Ever wondered about the costs involved in 3D printing with plastic? As an entrepreneur or business owner, grasping the financial aspects of such a dynamic industry is crucial. Concern often arises around the affordability and cost-effectiveness of 3D-printed plastic. Some find it hard to decode the various costs involved, from material expenses to machine usage and labor charges.

In this article, we will systematically demystify the cost breakdown of 3D printing plastic. By delving into the details of various factors affecting the cost, we’ll provide you with an in-depth understanding of where your money goes.

So, are you ready to dive into the fascinating world of 3D printing economics? Let’s embark on this knowledge journey together.

1. Understanding the Basics of 3D Printing Plastic

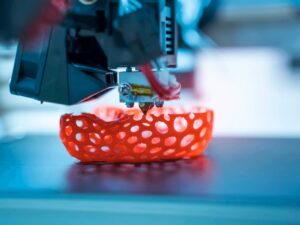

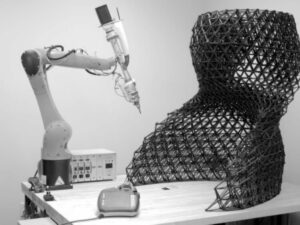

3D printing plastic is a complex process that transforms digital models into tangible objects. This process, also known as additive manufacturing, is accomplished by depositing layers of plastic one atop the other. As an entrepreneur, comprehending this fundamental principle is the first step towards mastering 3D printing economics.

According to Fortune Business Insights, the global 3D printing market size was valued at $18.33 billion in 2022 & is projected to grow from $22.40 billion in 2023 to $105.99 billion by 2030. Here’s the interesting part: businesses are heavily investing in this technology, highlighting its importance. So, learning the basics is no longer a choice but a necessity for survival and success in the evolving marketplace.

2. Applications and Benefits of 3D Printing Plastic

3D printing plastic is widely adopted across various industries due to its versatility and cost-effectiveness. Here, we will look at its common applications and benefits:

Applications of 3D Printing Plastic

Prototyping

Plastic 3D printing expedites the prototyping process, enabling faster design iterations and a reduction in time-to-market. And the best part is, the cost-effectiveness of 3D printing becomes evident when comparing the minimal tooling investment to the expenses of traditional manufacturing. For instance, traditional methods require expensive tooling investments, while 3D printing offers cost-efficient iterations without such costs.

Custom Parts Production

3D printing plastic enables the economical production of custom parts with complex geometries. This application finds use in various industries, including automotive, aerospace, consumer products, and more. 3D printing enables businesses to produce customized prototypes and one-off parts quickly and cost-effectively. It facilitates intricate designs, accelerates product development, and improves design optimization.

Medical and Dental Applications

3D printing plastic has revolutionized the medical and dental fields. It allows the production of patient-specific implants, surgical guides, anatomical models, dental prosthetics, and orthodontic devices. Technology enables precise customization, ensuring better patient outcomes and enhanced comfort. 3D printing plastic improves patient care and treatment planning in dental and healthcare fields.

Benefits of 3D Printing Plastic

Flexibility

One of the significant advantages of 3D printing plastic, such as the services offered by Suprotos, is its unparalleled design flexibility. It allows for the creation of complex and intricate geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This freedom of design enables innovative solutions, customization, and rapid iterations, catering to diverse needs and applications.

Speed

Compared to traditional manufacturing methods, 3D printing plastic can significantly reduce production time. The ability to fabricate parts layer by layer eliminates the need for complex tooling or assembly processes, streamlining the manufacturing workflow. Rapid prototyping and on-demand production capabilities enable faster time-to-market, empowering businesses to respond swiftly to market demands.

Cost-Efficiency

For low-volume production and prototyping, 3D printing plastic can be more cost-effective than traditional manufacturing methods, and I’ve personally witnessed how it eliminates the need for expensive molds, dies, or tooling equipment, resulting in significant upfront cost savings. Consolidating multiple components into a single 3D-printed part reduces costs, making it an attractive option for businesses.

3. Cost Breakdown of 3D Printing Plastic

To truly comprehend the cost of 3D printing plastic, it is essential to analyze and dissect the various factors that contribute to the overall expenses. Let’s explore each of these components in detail:

Material Costs

Material costs involve the expense of the plastic filament used in the 3D printing process. Here’s the interesting part: the type and quality of plastic can affect the price, with specialty filaments often being more expensive. Calculating the material costs includes considering the amount of filament consumed during the printing process.

Machine Usage Costs

Machine usage costs encompass the depreciation, maintenance, and electricity expenses associated with operating the 3D printer. These costs are calculated based on the machine’s lifespan, maintenance requirements, and power consumption during printing.

Labor Costs

Labor costs include the wages of the operators and technicians involved in the 3D printing process. And the best part is, these costs encompass not only the time spent preparing the digital model, operating the printer, monitoring the print job, and post-processing tasks, but they also vary based on the complexity and duration of the printing project.

Post-Processing Costs

Post-processing costs involve any additional steps or treatments required after the printing process. This can include cleaning, support removal, surface finishing, painting, or any other necessary post-processing tasks. The complexity and intricacy of the printed object can influence the amount of post-processing required and, consequently, the associated costs.

Additional Expenses

Additional expenses refer to any supplementary costs incurred during the 3D printing process. This category includes expenses for design software, quality testing, packaging materials, shipping, and any other unforeseen project expenses. According to TWI Global, 3D printing can also reduce costs on materials as it only uses the amount of material required for the part itself, with little or no wastage.

4. Methods To Reduce 3D Printing Costs

While 3D printing offers numerous benefits, entrepreneurs often look for ways to further reduce its costs. In a competitive market, implementing these cost-reduction strategies is as crucial as delivering high-quality products. Let’s explore each of these methods:

Optimizing Design

Optimizing the design involves designing the part specifically for additive manufacturing, taking advantage of its unique capabilities. By designing with considerations for support structures, material usage, and printability, it is possible to reduce the amount of material required and minimize post-processing efforts, ultimately lowering costs.

Material Selection

Choosing the right material can have a substantial impact on costs, and you see my point, right? By strategically selecting materials that strike a balance between quality and cost-effectiveness, businesses can effectively reduce expenses without compromising the desired properties of the printed parts. This ensures cost savings while maintaining functionality and performance requirements for successful outcomes.

Print Orientation

The orientation of a part during printing can significantly impact its strength, surface finish, and the amount of support material required. By leveraging Suprotos’ expertise and strategically orienting the part to minimize overhangs and maximize self-supporting features, businesses can effectively reduce material waste and achieve substantial savings in post-processing time and costs.

Batch Printing

Printing multiple parts in a single print run, known as batch printing, can dramatically enhance efficiency and substantially reduce costs. By optimizing build volume and part arrangement, businesses maximize space utilization, reduce printing time, and optimize resources. This approach allows for efficient production, minimizing material waste and optimizing resource allocation, leading to significant cost savings.

5. Pricing Models in the 3D Printing Industry

The 3D printing industry utilizes a range of pricing models to effectively address diverse customer needs and budgets. Let’s explore each of these models:

Pay-Per-Print

Pay-Per-Print pricing involves charging customers based on the number of prints. This pricing model typically includes the cost of materials, machine usage, and labor. Customers are billed according to the quantity and complexity of the prints they require. For instance, the calculation might consider factors such as the volume of material used, printing time, and the complexity of the part.

Subscription Models

Some 3D printing service providers offer subscription plans with fixed fees for a set number of prints or machine usage hours, benefiting recurring or frequent customers. But guess what I realized just in the nick of time? Subscription models not only offer cost savings and flexibility but also foster strong partnerships, ensuring a seamless and reliable 3D printing experience.

Bulk Ordering Discounts

To incentivize larger orders, many 3D printing service providers offer bulk ordering discounts. Here’s what we found instead: the pricing per print decreases as the volume of prints increases, which ultimately encourages customers to consolidate their printing needs and place larger orders, resulting in substantial cost savings.

Custom Quotes

For complex or unique projects, 3D printing service providers offer custom quotes. This pricing model takes into account various project-specific factors such as the complexity of the design, material requirements, post-processing needs, and any additional services requested. Custom quotes provide tailored pricing based on the specific project requirements.

6. Cost Comparison: 3D Printing vs. Traditional Manufacturing

When comparing the costs of 3D printing and traditional manufacturing can provide perspective on its economic viability, several factors come into play. Let’s explore the key cost comparison aspects:

Startup Costs

3D printing typically has lower startup costs compared to traditional manufacturing methods. The problem is, traditional manufacturing often requires significant investments in tooling, molds, and specialized equipment, which can lead to high upfront costs. In contrast, 3D printing eliminates the need for such expensive tooling, resulting in reduced initial expenses.

Unit Costs

Unit costs in 3D printing can be higher for large production volumes compared to traditional manufacturing, but it becomes more cost-effective for low-volume production or customized parts. Traditional manufacturing benefits from economies of scale, lowering unit costs with higher volumes. However, it becomes more cost-effective for low-volume production or customized parts, making it ideal for niche applications.

Lead Times

3D printing offers faster lead times compared to traditional manufacturing methods. But there’s a catch. With 3D printing, parts can be produced on-demand, eliminating the need for long setup times and tooling production. This enables rapid prototyping and quicker response to design iterations, reducing time-to-market. However, there are limitations in terms of production volume and material options that need to be considered. The following table compares lead times between 3D printing and traditional manufacturing methods, highlighting the advantages and limitations of each approach.

| Aspect |

3D Printing |

Traditional Manufacturing |

| Lead Time |

Faster |

Longer |

| Setup Time |

Minimal or No setup time required |

Significant setup time required |

| Tooling Production |

Not required |

Required |

| On-Demand Production |

Possible |

Not possible |

| Prototyping |

Rapid prototyping |

May require additional time for prototyping |

| Design Iterations |

Quicker response to design iterations |

Additional time may be required for design changes |

| Time-to-Market |

Reduced |

Potentially longer |

| Production Volume |

Limited |

Higher volume capability |

| Material Options |

Limited |

Wide range of material options |

7. 4 Factors Affecting the Cost of 3D Printing Plastic

Each factor plays a role in determining the overall expenses and should be carefully considered during the planning and budgeting stages of a 3D printing project. Understanding them can help in better financial planning. Let’s explore these key factors:

#1 Type and Quality of Plastic

The choice of plastic material affects the cost of 3D printing. Different types of plastics come with varying price points, with specialty or high-performance materials often being more expensive. Additionally, the quality of plastic, including factors like durability, strength, and surface finish, can impact the cost as well.

#2 Print Volume and Complexity

The size and complexity of the printed object, such as those handled by Suprotos, significantly influence the cost of 3D printing. For instance, larger prints typically require more material and time, resulting in higher costs. Additionally, intricate designs or objects with complex geometries may require additional support structures or post-processing, adding to the overall expenses.

#3 Printing Technology and Equipment

The choice of 3D printing technology and equipment can affect the cost. Different printing technologies have varying material requirements and operational costs. Here’s the main issue with that: some technologies, like stereolithography (SLA), may utilize specialized resins that are more costly, while others, like fused deposition modeling (FDM), may use thermoplastic filaments that are relatively more affordable.

#4 Finishing and Post-Processing

The level of finishing and post-processing required for the printed parts can impact the overall cost. And this is where people run into trouble. Finishing techniques such as sanding, polishing, painting, or adding surface textures may incur additional expenses. Similarly, post-processing steps like support removal, curing, or heat treatment can contribute to the total cost.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

In conclusion, understanding the cost of 3D printing plastic involves analyzing factors like material, labor, machine usage, post-processing, pricing models, and traditional manufacturing costs. We hope this article has provided valuable insights into the cost factors of 3D printing plastic. As you explore 3D printing, consider the financial aspect along with the benefits it offers, such as speed, flexibility, and customization.

Fortunately, there’s a simple solution. If you’re ready to explore the possibilities of 3D printing or have any questions, feel free to reach out to our team of experts at Suprotos. We are dedicated to providing guidance and support to help you harness the immense potential of this transformative technology.