#1 Material Selection

Material selection is imperative for the performance and durability of the injection molded parts. It is essential to take into account the environmental conditions and the physical stresses the parts will be exposed to. For example, Polypropylene (PP) is a popular choice for injection molding due to its high strength-to-weight ratio, high rigidity, and low moisture absorption.

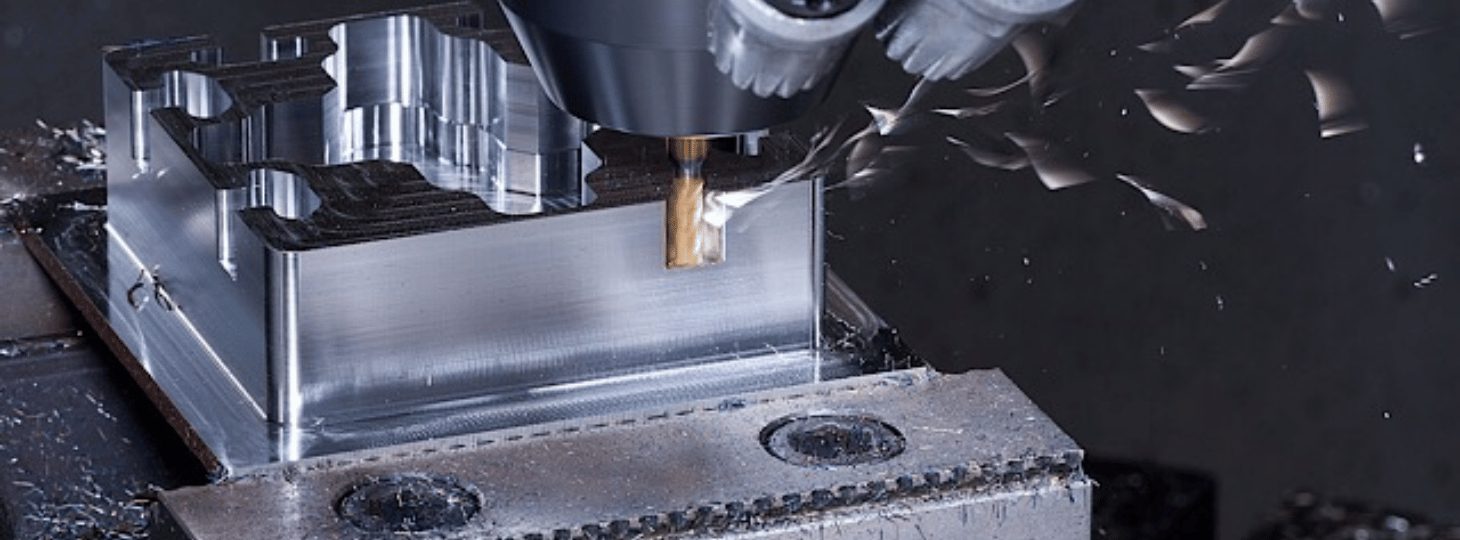

#2 Advanced Technology

It is vital to evaluate if the service provider integrates advanced technologies such as robotics and automation, which can increase efficiency and quality. Utilizing advanced practices can also contribute to waste reduction and cost-efficiency. Suproto is known for being committed to innovation and continuous improvement.

#3 Proper Arrangements

Assessing the lead time and scalability of the service provider is critical to ensure alignment with the project timeline. Establish proper arrangements regarding production schedules, and make sure they can scale production in response to fluctuating demands. Speaking from personal experience, clear communication and flexible arrangements with the injection molding service provider were indispensable.

#4 Expertise in Complex Designs

Ensure that the service provider has expertise in handling complex designs, particularly if the project involves intricate geometries or tight tolerances. They should have engineering-based knowledge and the capability to guide everything from design to manufacturing.

#5 Certifications

Checking for quality certifications such as ISO 9001 or AS9100 is paramount. It is also important to verify that they have a robust quality control process in place. Choose to work with a service provider that can demonstrate adherence to high industry standards through certifications and positive client testimonials.