Accuracy and Consistency

Precision metal stamping significantly enhances the accuracy and consistency of complex stamping applications. High-tech equipment facilitates the stamping, folding, drawing, or piercing of a product in single or series operations. This ability to produce highly accurate parts consistently is essential for various precision applications.

Versatility

Suproto’s metal stamping services cater to both low- and high-volume production runs. This versatility is particularly beneficial for all businesses as it allows them to optimize production schedules and costs, regardless of the quantity required.

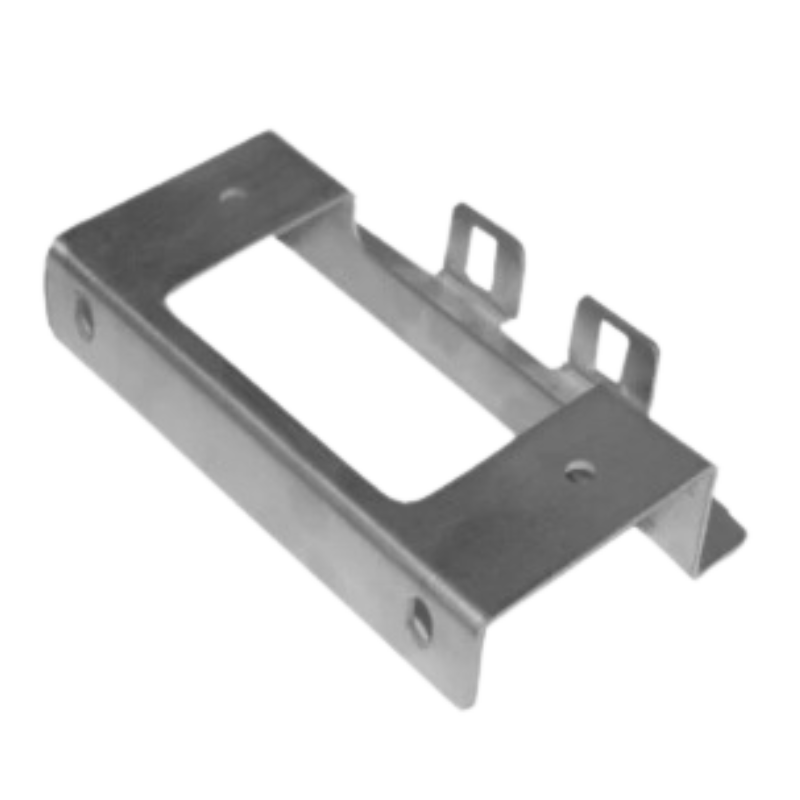

Custom Designs

With advanced tooling and machinery, metal stamping services can create intricate geometries and custom designs. This enables businesses to manufacture unique components tailored to their specific requirements. Custom metal stamping offers the advantage of precision and accuracy while allowing users to create their own designs, which are essential for industries that require specialized components.