Quality of Service

The paramount factor to consider is the quality and precision of the sheet metal fabricating service. This involves the accuracy of cuts, the consistency of output, the adherence to project timelines, and the ability to meet detailed design requirements. Assessing previous projects, client feedback, or requesting sample work can give you insights into the quality and precision of the service provider.

In evaluating global options, it’s also useful to consider the regional strengths and expertise in sheet metal fabrication. Notably:

Each of these countries has its own set of advantages and specialties in the field of sheet metal fabrication, contributing to the global market with unique capabilities and standards of quality.

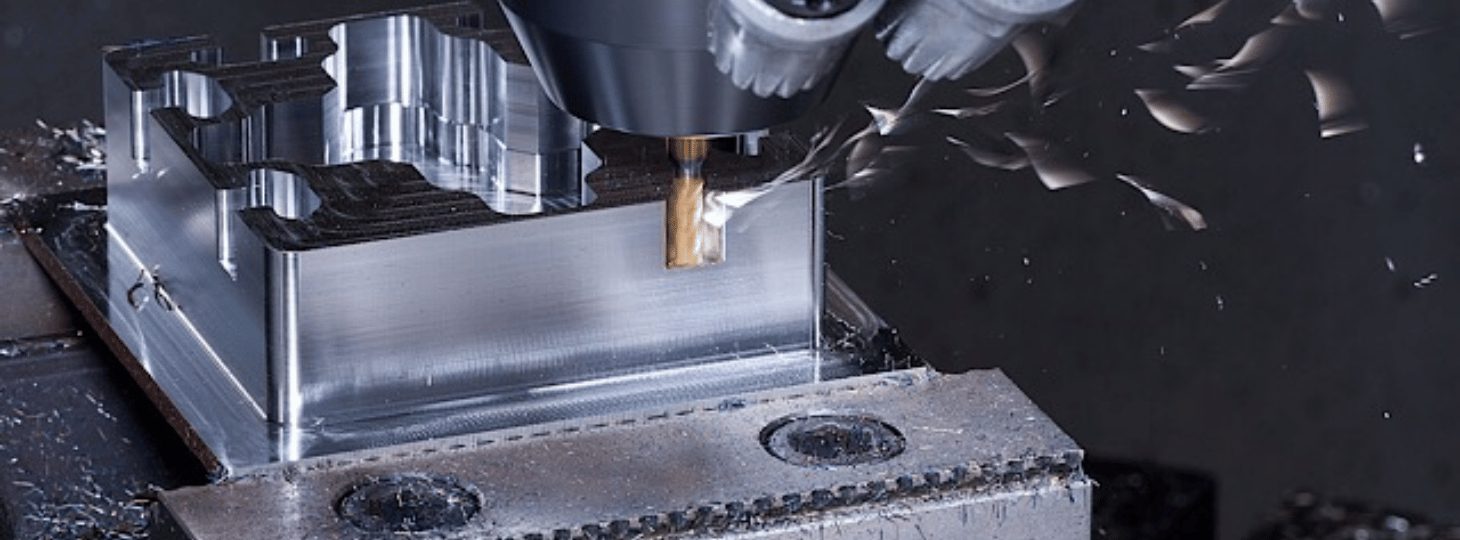

Technical Expertise

The technical expertise of the service provider can significantly impact the success of any project. This involves not just the skills to execute the project but also the ability to provide valuable input, foresee potential challenges, and offer effective solutions. I know anyone will agree, a service provider with robust technical expertise can ensure the smooth execution of the project, from design to completion.

Range of Services

Sheet metal fabrication involves a range of processes like cutting, bending, punching, and welding. The suitability of a service provider depends on whether they can offer all the services the project requires. Suproto stands out in this regard. Moreover, it’s also important to consider their expertise in working with different materials like stainless steel, aluminum, or copper.

Cost-Effectiveness

According to Local University Chicago, it is a main consideration to assure that the price to be paid for products and services is fair and reasonable. While seeking an affordable service is important, it’s equally important to ensure that the service provider can deliver high-quality work. This involves evaluating their pricing structure, understanding what is included in the cost, and ensuring there are no hidden charges.