Subtractive Manufacturing Process

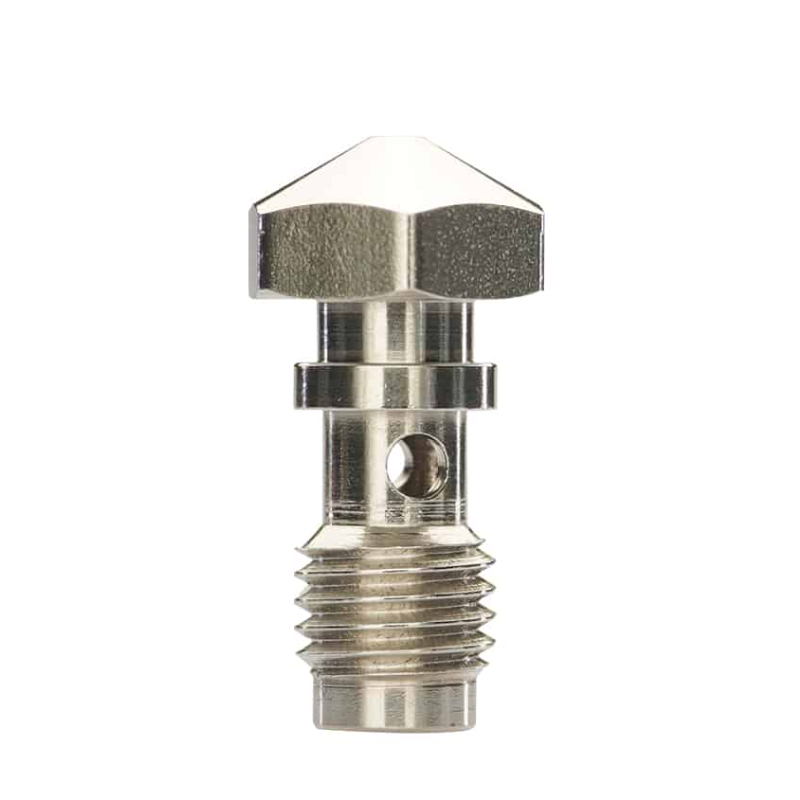

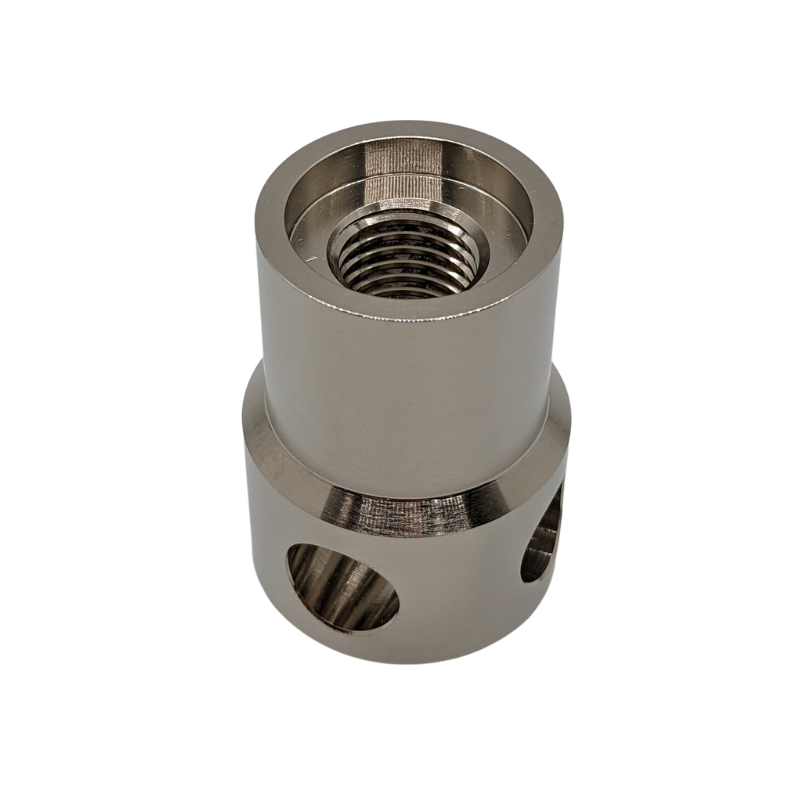

CNC turned components utilize a subtractive manufacturing process, where material is removed from a rotating workpiece using a non-rotating cutting tool. This offers exceptional control and precision, ensuring the creation of intricate parts with exacting specifications.

Computer Programmed

The process is programmed and controlled by computer numerical control (CNC), ensuring high accuracy. This technology facilitates the conversion of a CAD design into instructions for the machine, allowing for the creation of highly complex and precise parts.

Versatility

CNC turning centres, which can be part lathe and part mill, offer increased versatility. They are able to produce components with various shapes and sizes, even intricate designs that might be difficult or impossible to manufacture using other methods.

High Precision

Precision is a key attribute of CNC turned parts. These components are machined to an extremely tight tolerance, making them ideal for applications that require high precision, examples are automotive manufacturing, aerospace, and medical industries. Suproto’s commitment to precision and excellence is evident in every component they produce, providing customers with reliable, high-performance parts.

Safety in Operations

One of the less talked about, but equally important features, is the safety of CNC turning operations. Unlike manual operations, the hands-off nature of CNC machines significantly reduces the risk of accidents during the manufacturing process.