As per Grand View Research, the global 3D printing construction market size was valued at USD 18,175.7 thousand in 2022 and is projected to register a compound annual growth rate (CAGR) of 101.9% from 2023 to 2030. Since architectural 3D printing services have continuously moved up in the industry, here are the crucial factors that must be taken into account:

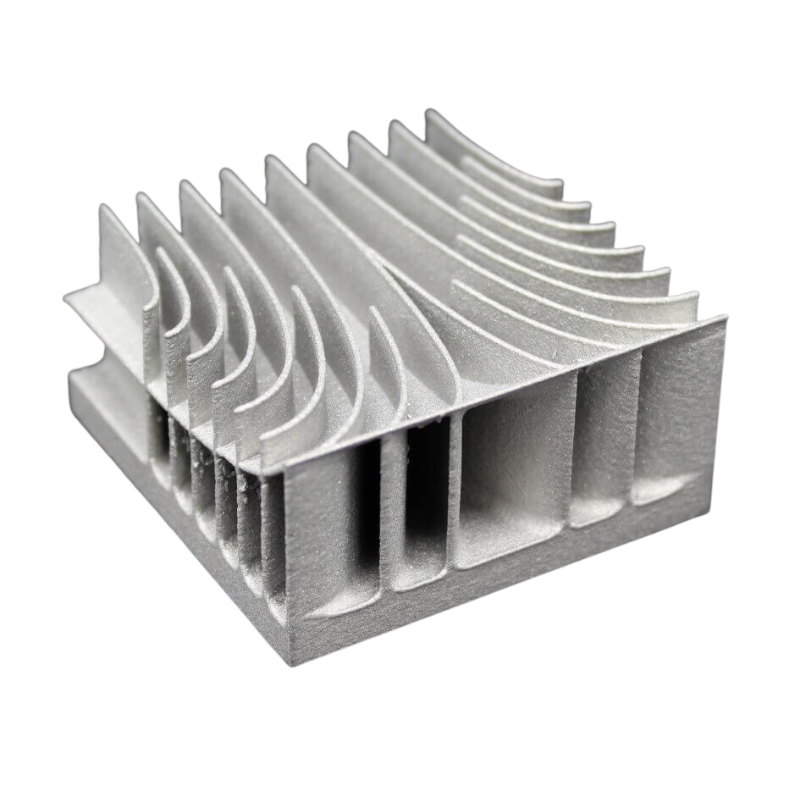

#1 Standard Materials

When choosing a 3D printing service, it is vital to assess the quality of the printers and materials they use. For example, a company using industrial-grade printers and high-quality filaments will produce more durable and detailed models than one using consumer-grade equipment.

#2 Consultation Services

Aside from good customer support, it is essential that the service provider should offer consultation and support throughout the project, helping to choose the right materials and optimize the designs for business 3D printing.

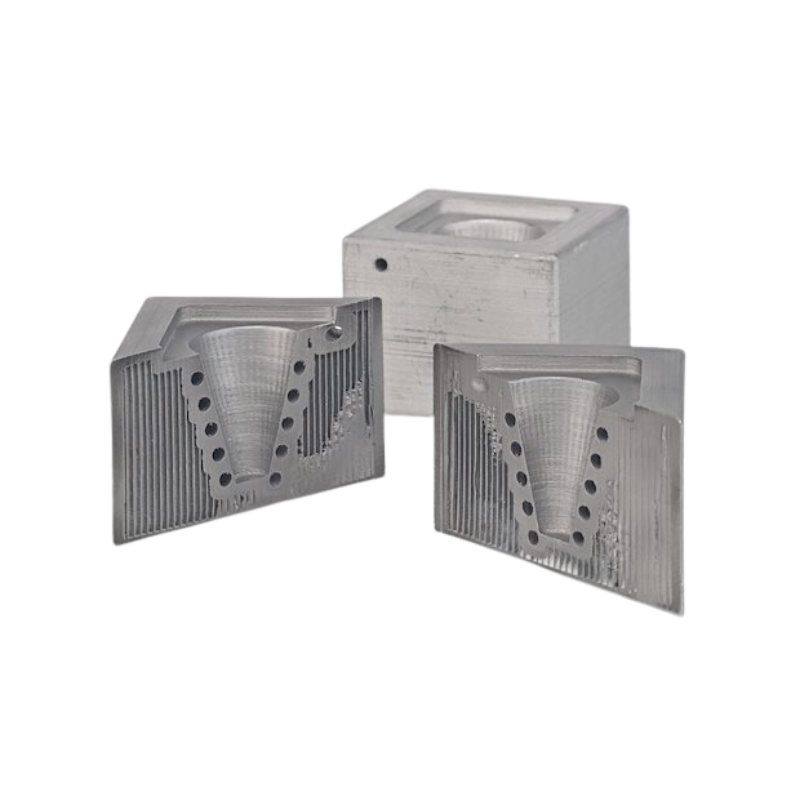

#3 Customization Options

Customization is one of the main advantages of 3D printing. Ensure that the service provider offers a range of customization options, from materials and colors to scale and complexity. I can tell that 3D printing technology has been increasingly utilized for mass customization, particularly in industries like healthcare, automotive, and construction, with its ability to create objects with complex designs.

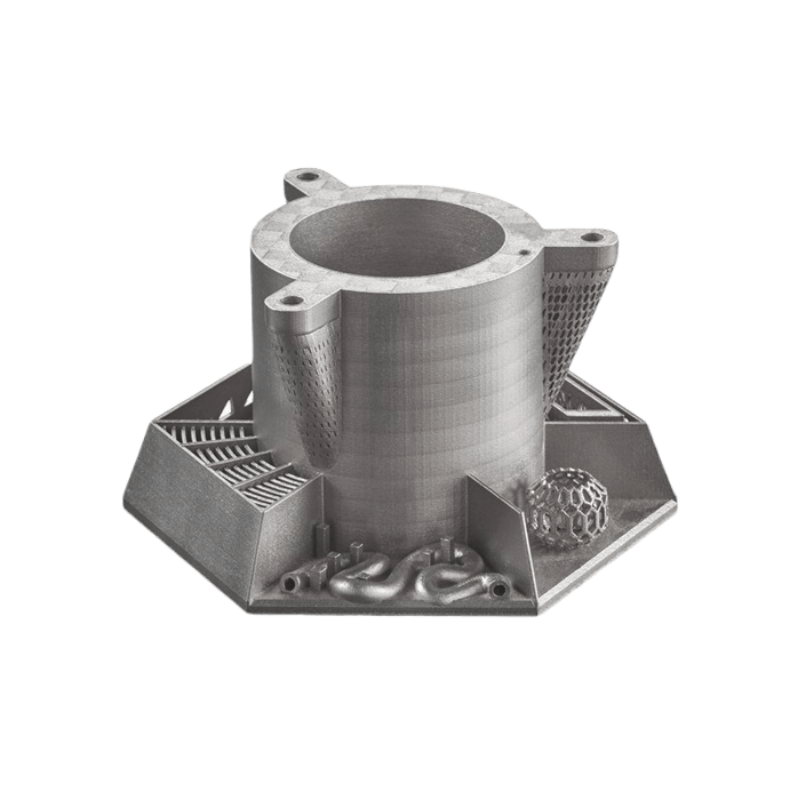

#4 Review Previous Projects

Looking at the company’s previous projects and reading client testimonials can give insights into their expertise and reliability. Suproto, for example, we have successfully executed complex architectural projects with positive client feedback. It is likely to be a good choice.

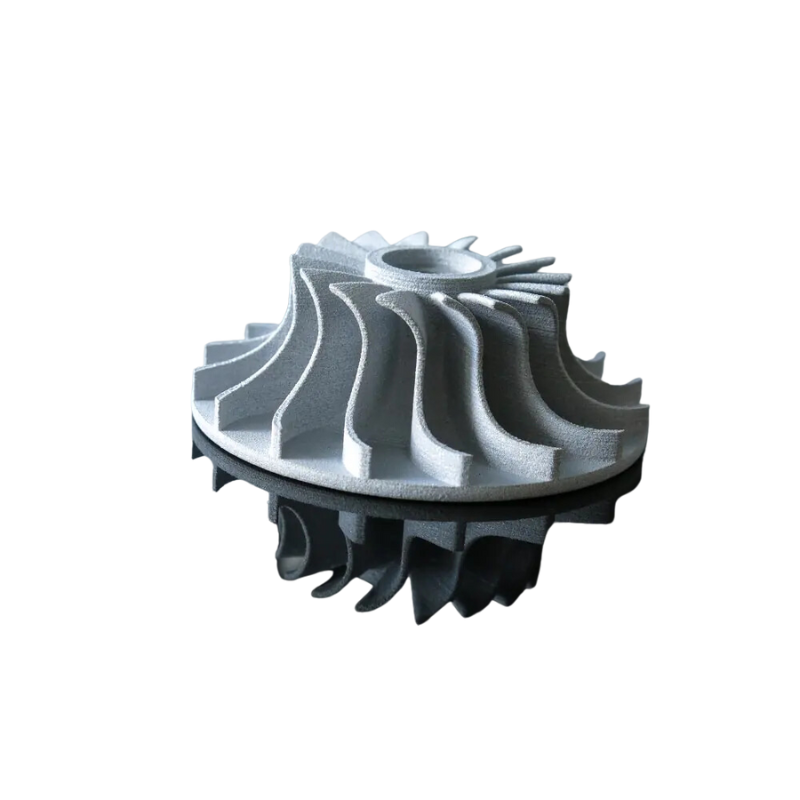

#5 Turnaround Time

Turnaround time is crucial in architectural projects. Ensure that the 3D printing service can deliver high-quality models within the given timeframe. Additionally, check if they have the capability to scale up production if needed.