According to Global News Wire, the global EDM market was valued at around USD 4.65 billion in 2017, expected to reach approximately USD 7.97 billion in 2024 with CAGR of slightly above 8.1% between 2018 and 2024. In the market for high-quality, precision manufacturing, Sinker EDM services emerge as a front runner. With that, here are the essential considerations that should be contemplated:

#1 Expertise and Experience

When selecting a Sinker EDM service, consider the expertise and experience of the service provider. Wanting a company that has a proven track record of delivering high-quality results and has a thorough understanding of the complexities involved in Sinker EDM machining. Suproto has established its credibility in this field, continually providing precision results.

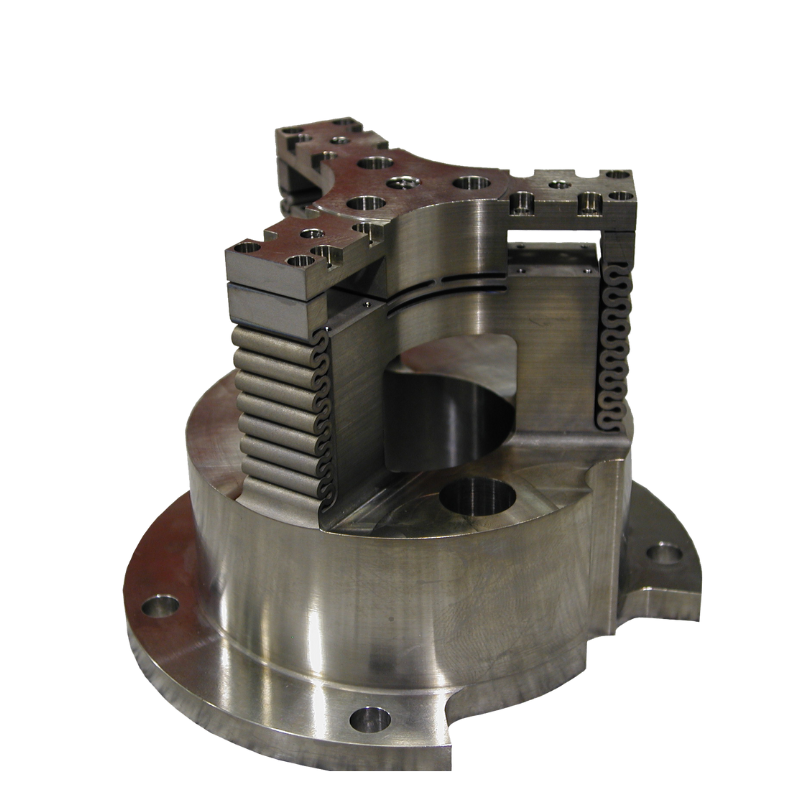

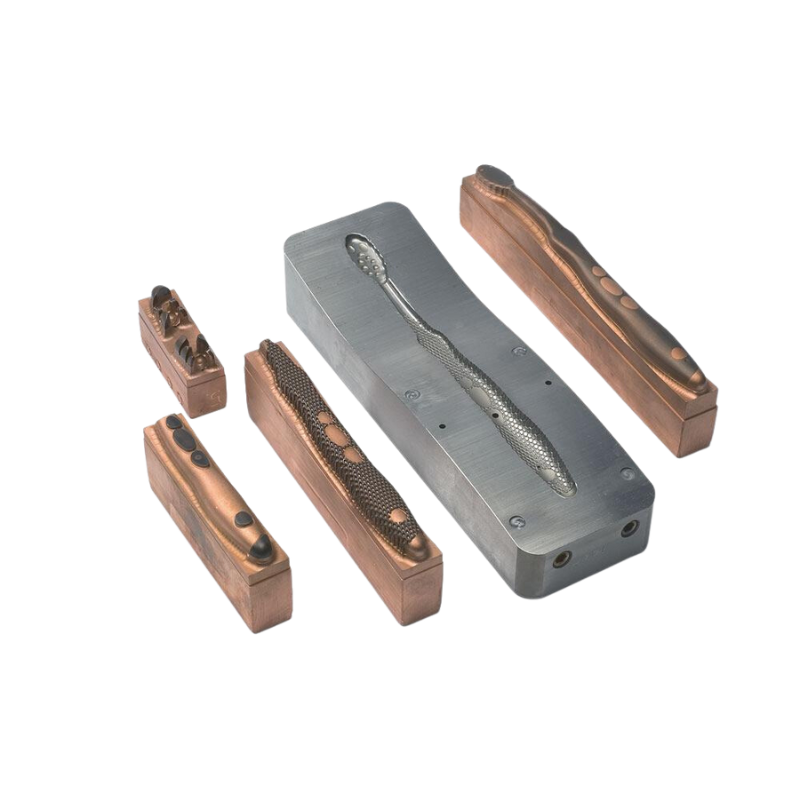

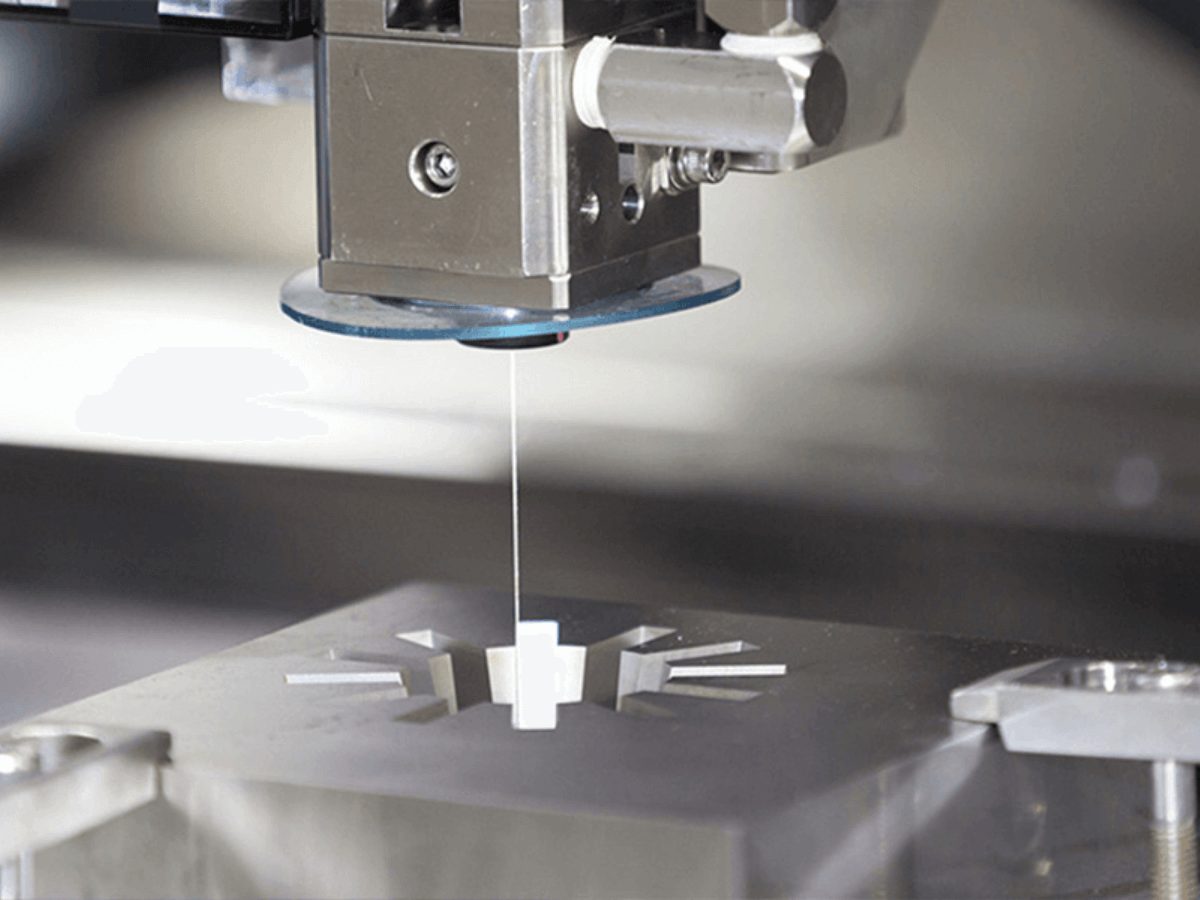

#2 Technological Capability

The efficiency of Sinker EDM services lies significantly in the technology being employed. A service provider with state-of-the-art equipment and updated software can ensure better accuracy and faster turnaround times.

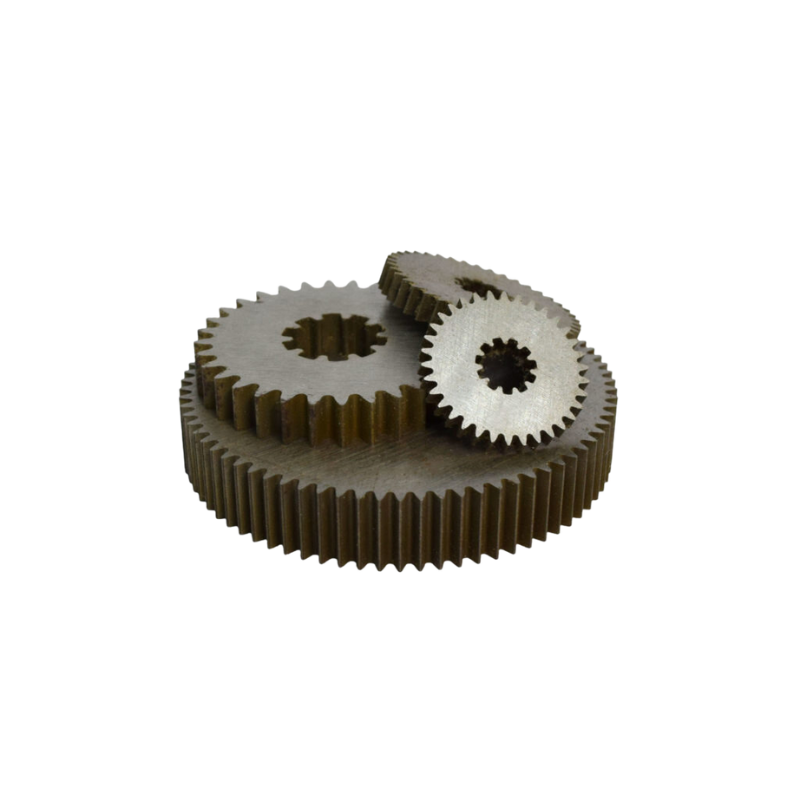

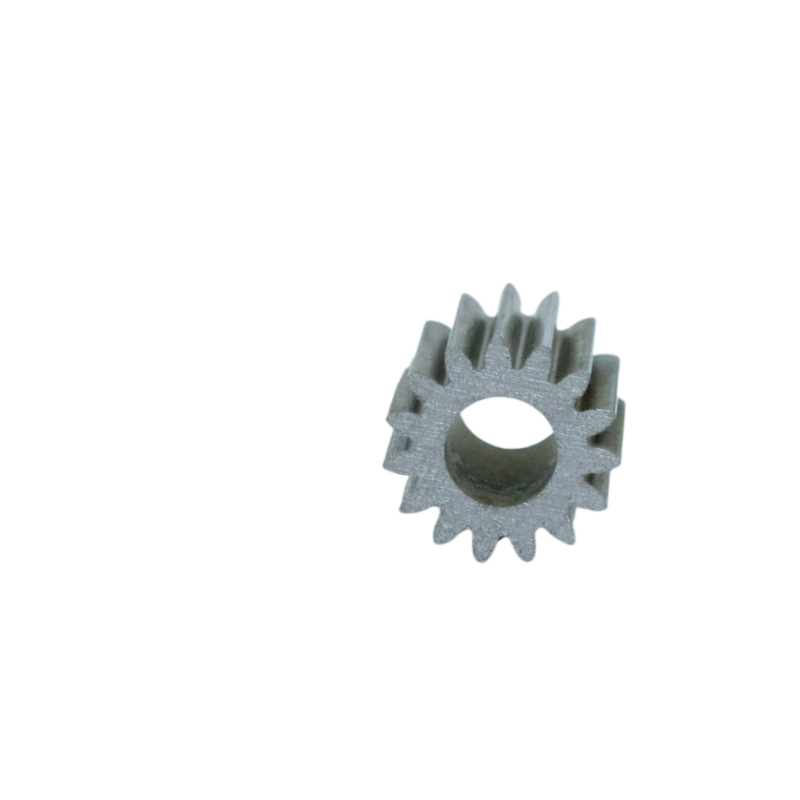

#3 Material Understanding

Each material behaves differently under the Sinker EDM process. Therefore, it’s crucial to choose a service provider who understands the material that businesses are working with and can adjust the process to achieve optimal results.

#4 Quality Assurance

Ensure the Sinker EDM service provider has a solid quality assurance process in place. This entails regular inspections and checks to confirm that the machined parts meet the desired specifications and quality standards.

#5 After-Sale Support

Good service providers stand by their work and are ready to address any concerns or issues that may have after the delivery. As such, a company that offers excellent after-sale support signifies their commitment to customer satisfaction. The EDM services market valued customer service highly, with top-rated firms receiving increased demand.