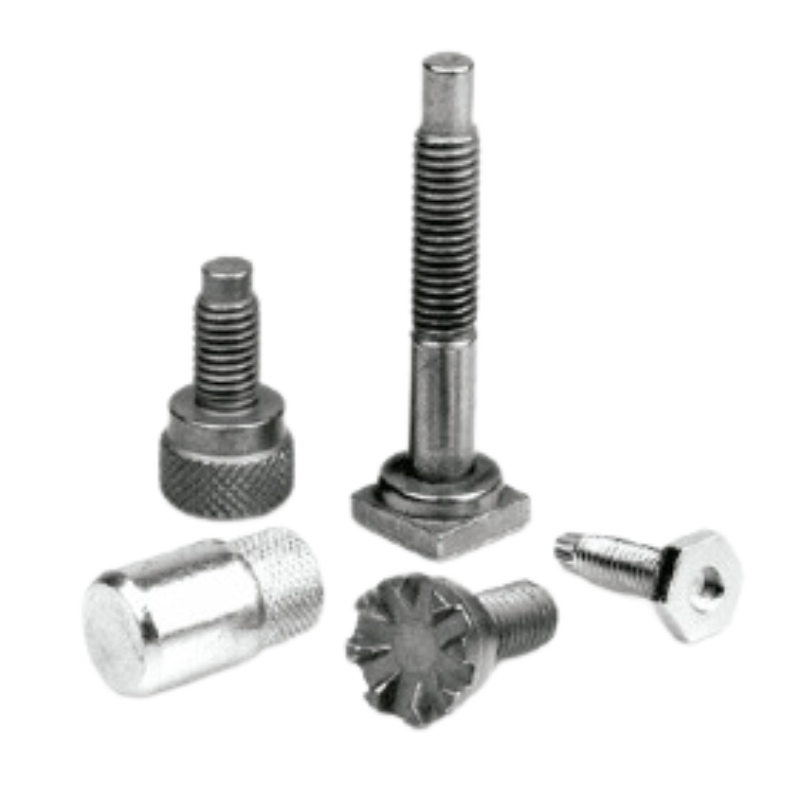

#1 Material Compatibility

When choosing an overmolding service, it’s vital to ensure that the materials intended to combine are compatible with each other. For example, some plastics may not adhere well to certain metals, and knowing this beforehand can save time and resources.

#2 Complexity and Costs

Evaluate the complexity of the product design and weigh it against the cost implications. Overmolding requires a more complex mold setup process, which can be costlier than traditional methods. Understanding this aspect is essential, especially if dealing with specialty parts or high-volume production.

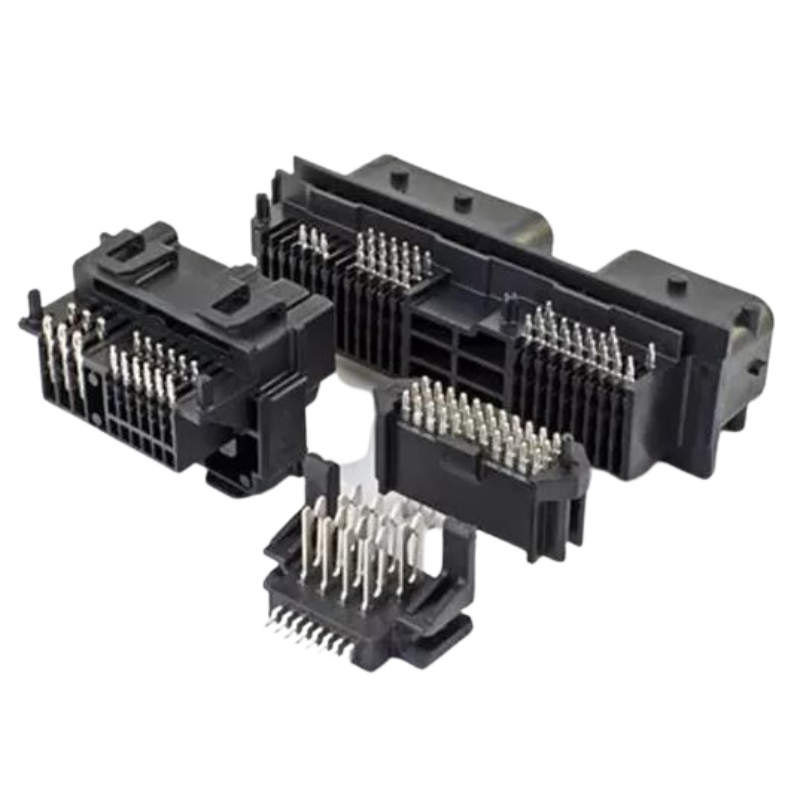

#3 Precision and Quality Control

Look for an overmolding service provider that can assure precision and adhere to stringent quality control standards like Suproto. This is especially crucial in industries like medical manufacturing, where products must meet specific regulatory requirements.

#4 Volume and Scalability

Determine the volume of production and assess whether the overmolding service can scale according to the needs. Based on experience, I can tell that overmolding is more efficient for high-volume production, but it must be ensured that the service provider has the capacity to meet production levels.

#5 Technical Support Expertise

Assess the level of technical support and expertise the service provider offers. Invozone says, providing technical support to customers is also one of the most crucial factors contributing to business growth. A KPMG study suggests that customer retention is crucial for revenue growth and exceptional tech support initiatives can prove beneficial for organizations.