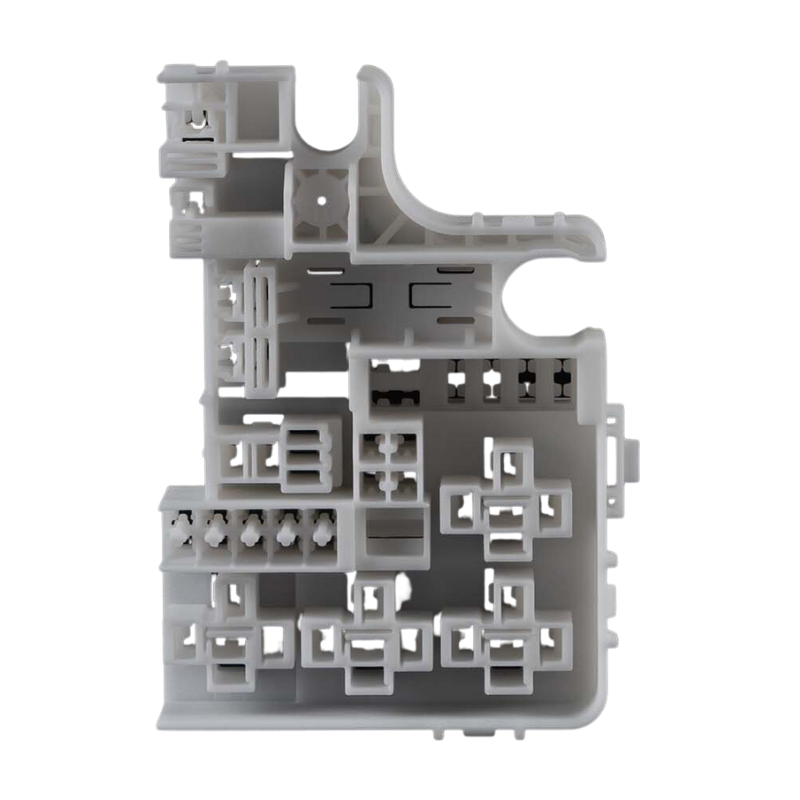

Complexity and Freedom of Design

SLS allows for the creation of intricate geometries, interlocking parts, and even parts within parts. This freedom makes it a preferred choice for highly intricate designs that would be impossible to create using traditional manufacturing methods. An example is in the eyewear industry, where a manufacturer used SLS 3D printing to produce unique and custom-made eyeglass frames.

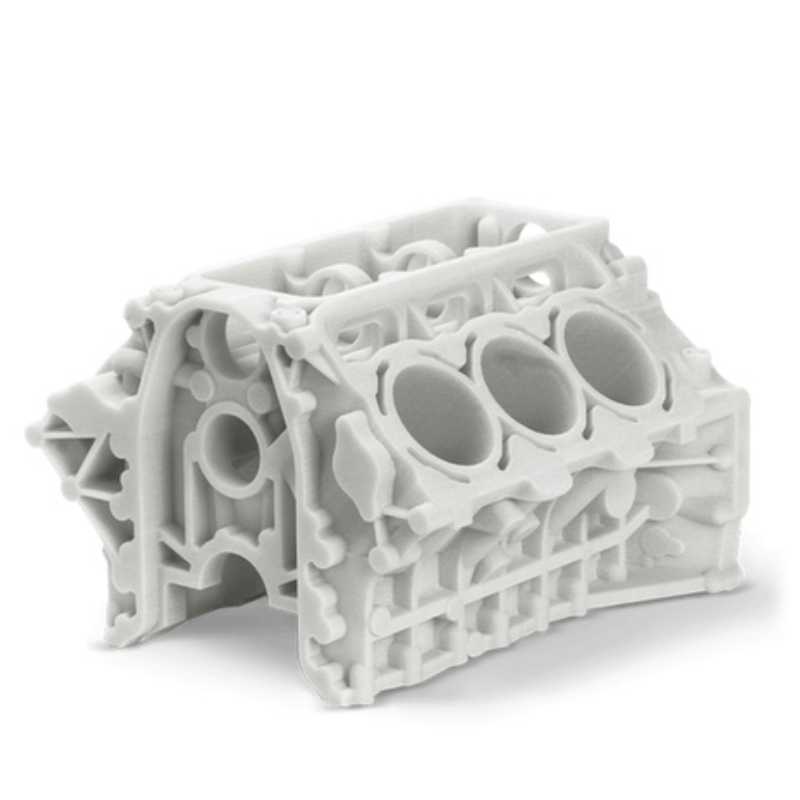

Durability and Functionality

SLS printed parts are exceptionally durable and functional. These parts are not only prototypes but are often end-use parts due to their high strength and temperature resistance.

Batch Production Capability

Unlike other 3D printing methods, SLS supports the simultaneous production of multiple parts in a single batch. This feature allows for cost-effective and efficient mass production. In my experience, this capability can be a real game-changer when dealing with large-scale or high-volume projects.

Material Diversity

SLS can use a variety of materials, ranging from nylon to metals. This diversity broadens its applicability across numerous industries. Capitalizing on this versatility, Suproto offers a comprehensive selection of materials, expanding possibilities for customer projects and unique applications.

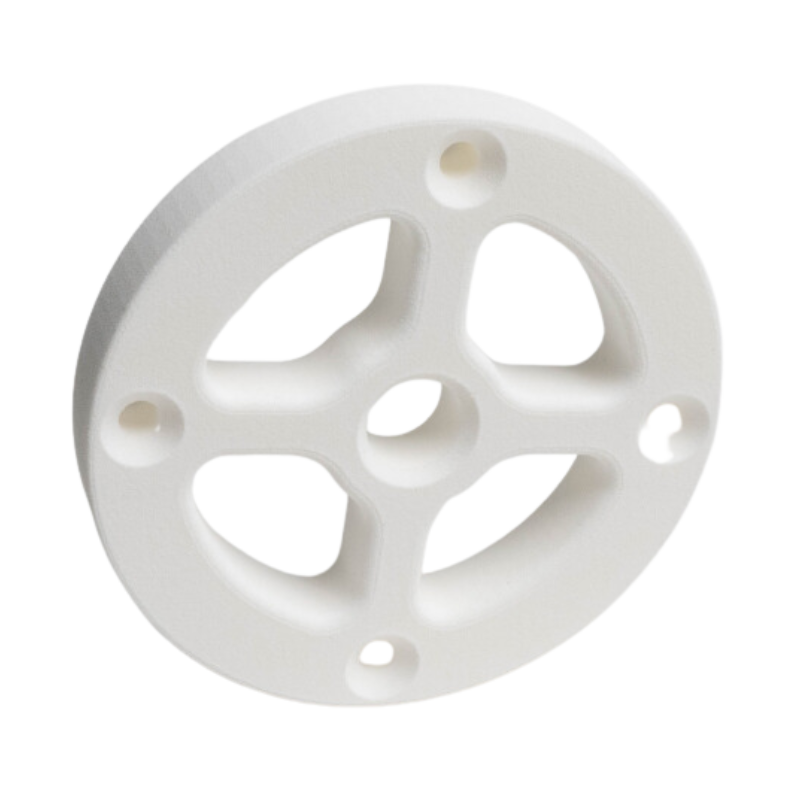

No Support Structures Needed

One significant advantage of the SLS technique, offered by 3D printing service, is that the powder acts as a built-in support. This characteristic eliminates the need for additional support structures, reducing post-processing time.