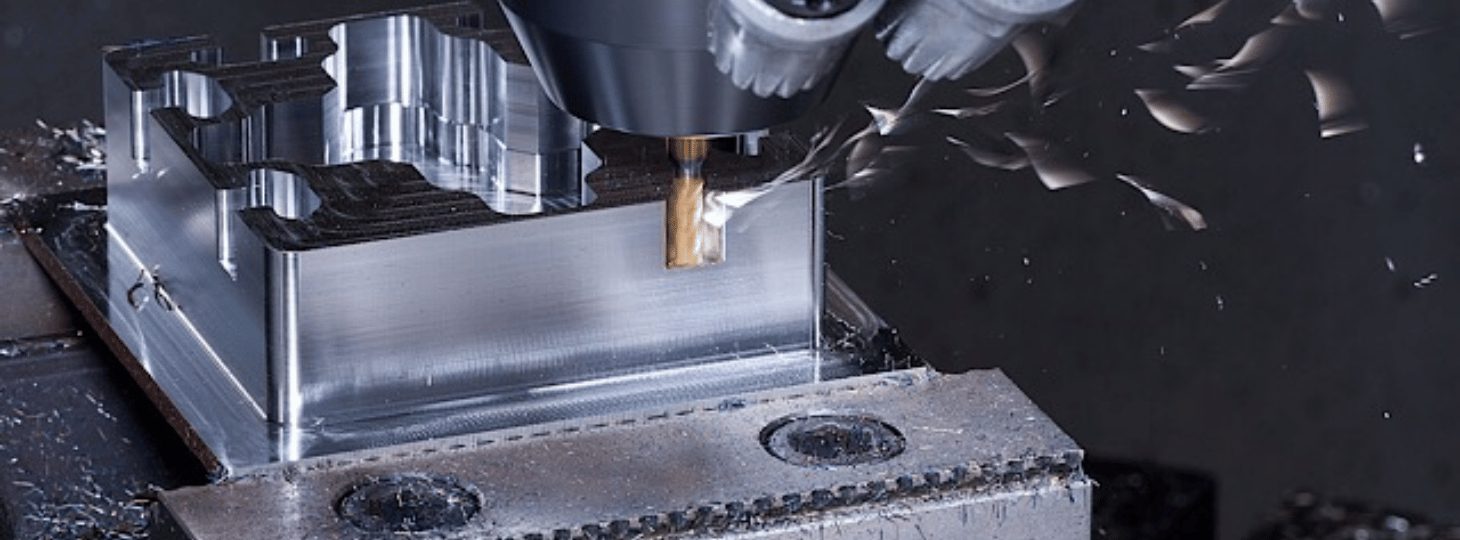

Product Development

The power of rapid prototyping businesses can significantly accelerate their product development cycles. This method facilitates the early identification of design imperfections, thereby curtailing unnecessary expenditure and streamlining timelines. For example, it enables the swift creation and evaluation of intricate geometric shapes, providing a pragmatic avenue for fine-tuning design intricacies and eliminating costly reiterations.

Testing and Refining Designs

Employing rapid prototyping, engineers and designers unlock a robust capability to scrutinize, test, and refine their designs with profound efficiency. This groundbreaking technology serves as a key facilitator in the production of precision-driven models, granting the luxury of comprehensive checks on all aspects of functionality and durability.

Presenting New Concepts

Rapid prototyping is used to present new product concepts to stakeholders. It brings ideas to life and helps secure approval or funding more quickly. According to Grand View Research, Inc., the global rapid prototyping material market is projected to reach a value of USD 2.6 billion by 2025, growing at a 30.9% CAGR. Companies like Suprotos are central to this revolution, helping businesses turn their concepts into reality.