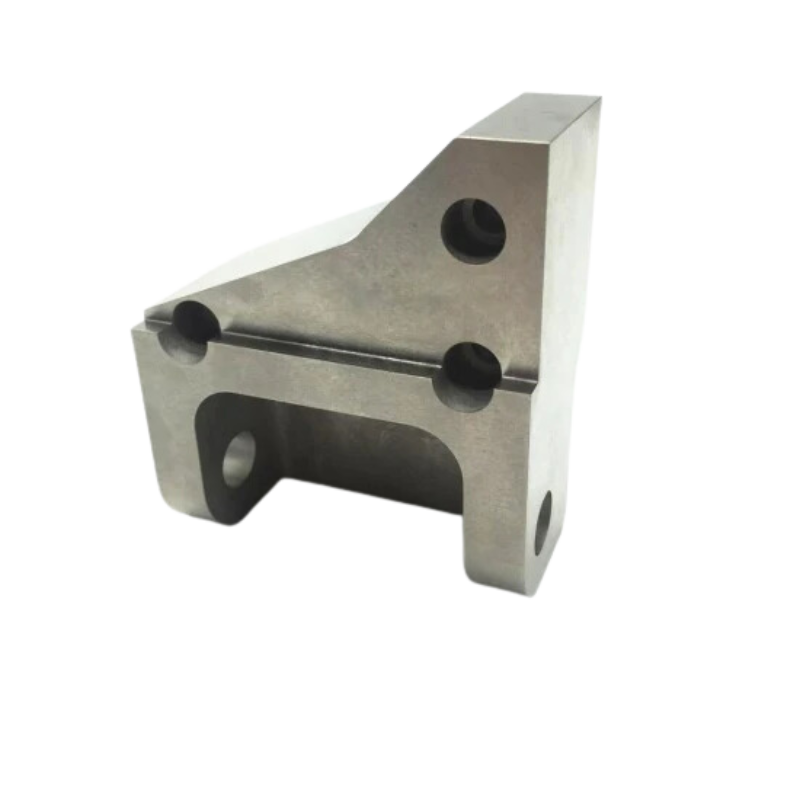

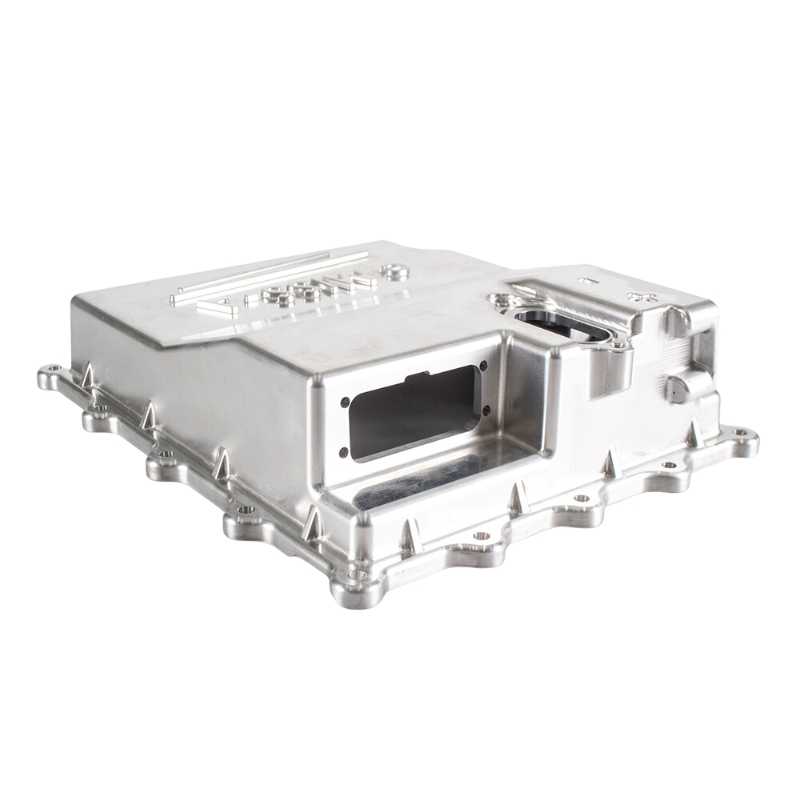

High Precision and Accuracy

CNC prototyping stands out for its exceptional precision and accuracy. Unlike traditional manufacturing methods, CNC prototyping is fully automated, with pre-programmed software directing the tools’ movements. Trust me, this digital precision ensures the consistency of each part, achieving accuracy down to the micrometer.

Versatility

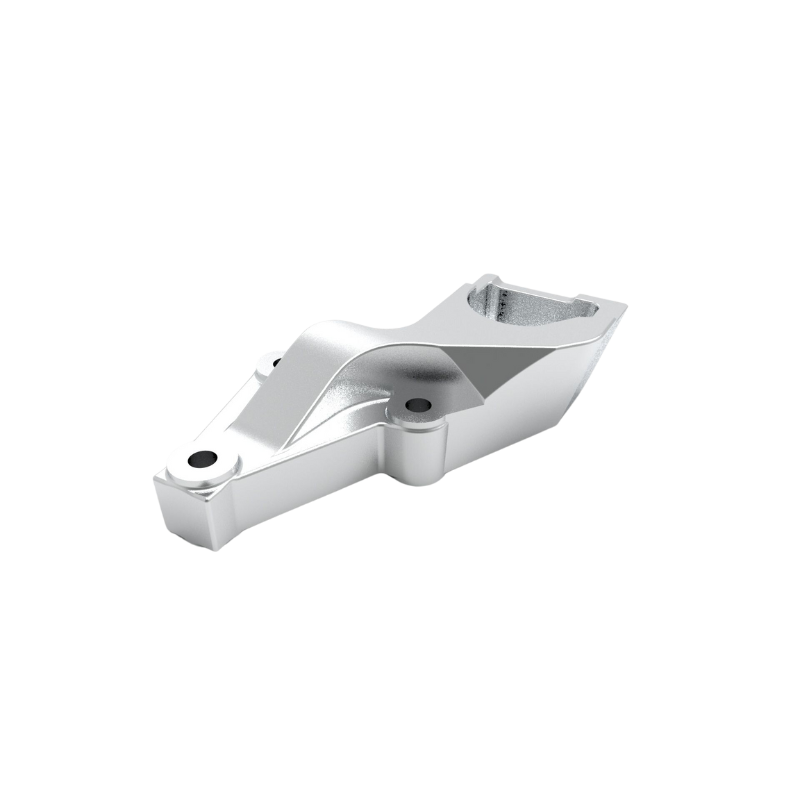

The versatility of CNC prototyping is another of its standout features. It’s not just about working with different materials, from robust metals to versatile plastics. CNC prototyping of Suproto shines in its ability to produce a broad spectrum of parts and components, no matter how complex. Whether anyone need a one-off prototype cnc machining or a low-volume production run, CNC prototyping can handle it all.