In the bustling landscape of manufacturing, China is emerging as a forerunner in CNC prototyping. But what’s the buzz all about? Is it just cost-saving, or is there more to this trend?

China’s CNC prototyping is revolutionizing the way products come to life, by blending affordability with cutting-edge precision. Through the course of this article, we will uncover how China’s evolving CNC technologies, honed since 1958, play a crucial role in this revolution.

Looking to turn the concept into reality efficiently? Read on to unlock the secrets behind China’s CNC prototyping marvel!

1. Understanding CNC Prototyping

Computer Numerical Control (CNC) prototyping is a revolutionary process that has changed the way products are designed and developed. It involves creating physical models or actual products from digital designs using computer-controlled machines. In manufacturing, CNC prototyping is vital as it enables the swift and precise production of small-scale parts or entire products.

This is crucial in the product development stage as it allows engineers and designers to examine the feasibility, functionality, and aesthetic of a design before transitioning to mass production. Moreover, CNC prototyping ensures the high repeatability and consistency of the produced parts, thanks to the high level of automation and advanced software, which eventually translates to cost savings and high-quality outputs.

2. Evolution of CNC Prototyping in China

Early Beginnings

China embarked on its CNC journey in 1958 when Tsinghua University produced the country’s first computerized numerical control machine. I believe, this time technology was limited, and CNC machines were mainly used for the military or aerospace industries due to the country’s economic and industrial recovery post World War III. The machines of this era were basic but laid the groundwork for future advancements.

Middle Ages

The 1980s marked a new era for CNC prototyping in China, characterized by economic reforms and globalization. China’s CNC industry began serving civilian purposes, as the country gradually became the world’s industrial center. However, they primarily functioned as advanced tools for mass production. It wasn’t until China emerged as the world’s largest automotive manufacturer in the 1990s that the transition began.

Present

Now, China has carved a niche for itself in the CNC prototyping space. With substantial investments in technology, infrastructure, and research & development, Chinese CNC machines now boast cutting-edge technology. This has led to remarkable improvements in speed and tolerance, the two most essential standards in the CNC prototyping industry. I see China has become a hub for prototyping services today.

3. Advantages of CNC Prototyping

Precision and Accuracy

One of the stellar advantages of CNC prototyping is its impeccable precision and accuracy. When it comes to manufacturing parts, even the minutest discrepancy can wreak havoc on the final product. Advanced technology ensures that every part is produced with a high degree of precision, adhering to exact specifications. I have seen with the development of technology accuracy has seen leaps and bounds.

Rapid Production and Turnaround

Additionally, CNC prototyping is synonymous with speed. Time is of the essence in today’s fast-paced world, and CNC prototyping is the hare in the race. The high degree of automation ensures that parts are produced at a breathtaking pace. At Suproto, we believe that the quick turnaround time is not just limited to production but also the ability to make on-the-fly changes to design.

Wide Range of Material Options

Lastly, the flexibility in material options is like a cherry on top. I can Imagine a wizard with a magic wand, able to transmute things into any material. That’s what CNC prototyping feels like. From metals like aluminum and steel to plastics and even wood, the list is exhaustive. This versatility opens up a myriad of possibilities across various industries, be it aerospace, medical, or automotive.

4. CNC Prototyping Process

Venture with me as we demystify the CNC Prototyping Process, a journey from concept to realization. Let’s take a look at the overview process below:

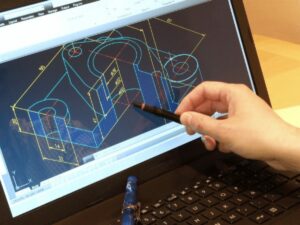

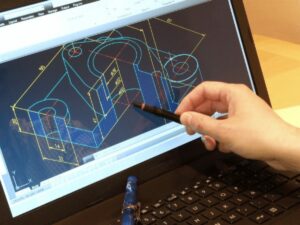

Step#1 CAD Designing

Our journey commences with CAD (Computer-Aided Design). Like an architect’s blueprint, CAD is where the initial design of the part is created. This digital design, for example, acts as the north star guiding the CNC machines. Crafted with utmost precision, this step is crucial as the machines will adhere to this design down to the last micron.

Step#2 Programming

After the design is polished to perfection, next up is programming. This stage is where the digital design is translated into a language the CNC machine understands. It’s akin to a symphony being composed, where each movement is meticulously orchestrated to ensure harmony. From my point of view, the tool paths are programmed to ensure efficient and precise production.

Step#3 Machining

As we delve deeper, we enter the heart of the process – machining. This is where the rubber meets the road. The CNC machine, armed with design and programming, gets down to business. For example, think of a sculptor chiseling away the machine and precisely carving the material into the desired shape.

Step#4 Quality Control

Finally, as our journey nears its end, the crowning jewel is quality control. This stage is the guardian, ensuring that each part is up to the mark and in sync with the design specifications. It’s important to ensure that the final product isn’t just produced rapidly, but is also of the highest quality. Companies like Suproto are well known for their stringent quality control, ensuring customer satisfaction.

5. Applications of CNC Prototyping

Automotive Industry

This sector, known for its high-speed performance and precision engineering, has embraced CNC prototyping like a long-lost friend. Utilized for creating everything from intricate engine components to breathtakingly sleek car bodies, CNC prototyping has been pivotal in driving innovation. Moreover, with the advent of electric vehicles, the complexity and precision required in manufacturing have risen.

Aerospace Sector

Here, there are zero margins for error, and CNC prototyping fits the bill perfectly. In my experience, the ability to create lightweight, yet durable components, is paramount in aerospace. From turbine blades to cockpit instruments, CNC prototyping allows for the creation of highly specialized parts that can withstand the extreme conditions of space and high-altitude flight.

Medical Industry

Now, let’s step into the life-saving domain of the medical industry. For me, in this field, precision is not just crucial; it’s a matter of life and death. CNC prototyping is extensively used for making surgical instruments, implants, and even intricate components of medical devices. With CNC prototyping, personalized medical equipment that caters to specific patients can be produced, revolutionizing patient care.

6. How China Dominates the CNC Prototyping Industry

Technological Innovation

Setting the stage for China’s dominance is its unrelenting focus on technological innovation. China has transformed itself into a global manufacturing powerhouse, with CNC prototyping being one of its crowning jewels. According to ITA, Over the past ten years, China’s domestic market supported approximately 70% of locally-made machine tools. China has catapulted itself to the forefront of CNC technologies.

Skilled Workforce

Furthermore, China’s supremacy can be attributed to its highly skilled and dedicated workforce. With a rich history of craftsmanship and an emphasis on technical education, China has fostered a workforce that is adept at handling the nuances of CNC prototyping. Believe me, this pool of talent ensures that the high standards required in CNC prototyping are not just met but exceeded.

Competitive Pricing

Finally, the trifecta is completed with China’s competitive pricing. Through economies of scale, efficient production methodologies, and a vast supply chain, China has been able to offer CNC prototyping services at prices that are highly competitive. At Suproto, we have seen this has made it an attractive destination for businesses around the globe looking for high-quality CNC prototyping without breaking the bank.

7. Choosing the Right CNC Prototyping Service in China

Quality Assurance

Quality assurance is the backbone of any manufacturing venture, and when it comes to CNC prototyping, it’s no different. To ensure that the prototypes meet the highest standards, it is essential to partner with a service that is laser-focused on quality. Trust me, look for companies that have robust product testing, verification processes, and certifications like ISO 9001:2015, which attest to their commitment to excellence.

Technology Utilization

Another critical aspect to consider is the technology utilized by the CNC prototyping service. With advancements in CNC technologies, it’s pivotal that the service to choose is up-to-date with the latest in machining equipment. The utilization of state-of-the-art CNC machines and post-processing systems is a telltale sign of a service that can deliver products of the highest quality.

Customer Service

Thirdly, in this interconnected world, effective communication and customer service play a significant role in the success of the project. Choose a CNC prototyping service that offers improved communication, to easily keep track of the machined parts. According to Gartner Research, “89% of companies now expect to compete mostly on the basis of customer experience.”

Intellectual Property Protection

Last but certainly not least, intellectual property protection is a paramount consideration. The CNC prototyping process often involves handing over intricate designs, and it’s crucial that these remain secure. Thankfully, China has taken dramatic steps to improve its intellectual property laws, which means there is confidence in handing over the designs to a Chinese machine shop.

The table provides an overview of intellectual property protection in China, highlighting its legal framework, protection measures, enforcement mechanisms, and the confidence in handing over designs to Chinese machine shops.

| Aspect |

Intellectual Property Protection |

| Country/Region |

China |

| Legal Framework |

China has taken dramatic steps to improve its intellectual property laws. |

| Patent Protection |

Chinese patent laws provide protection for inventions and technical innovations. Patents can be registered with the State Intellectual Property Office (SIPO). |

| Copyright Protection |

China’s copyright laws protect original literary, artistic, and scientific works, including computer software. Copyrights can be registered with the National Copyright Administration (NCAC). |

| Trademark Protection |

Chinese trademark laws protect registered trademarks, including logos, names, and symbols. Trademarks can be registered with the Trademark Office of the State Administration for Industry and Commerce (SAIC). |

| Trade Secret Protection |

China has enacted laws to protect trade secrets and confidential business information. Companies can take legal action against unauthorized disclosure or misappropriation of trade secrets. |

| Enforcement Mechanisms |

China has established specialized intellectual property courts to handle IP-related disputes. There are also administrative bodies, such as SIPO and NCAC, responsible for enforcement and dispute resolution. |

| Anti-Counterfeiting Measures |

China has implemented various measures to combat counterfeiting, including enhanced customs enforcement, stricter penalties for intellectual property infringement, and cooperation with international organizations. |

| International Agreements |

China is a signatory to several international agreements related to intellectual property protection, including the Berne Convention, the WIPO Copyright Treaty, and the Agreement on Trade-Related Aspects of Intellectual Property Rights (TRIPS). |

| Confidence in Chinese Machine Shops |

Due to China’s improved intellectual property laws and enforcement measures, there is confidence in handing over intricate designs to Chinese machine shops. However, it is advisable to exercise caution and ensure appropriate contracts and agreements are in place to protect intellectual property rights. |

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

As we dive into China CNC prototyping, we have seen it is an essential service that can cater to the specific needs of businesses. Considering the complexity and prolonged decision-making process in the business space, the question is how to ensure CNC prototyping requirements are met efficiently and accurately.

Engaging with a reliable partner for China CNC prototyping can empower you with high-quality, precise products essential for business operations. For any questions and insights on how to make the best out of the business CNC prototyping strategies, do not hesitate to contact us. Our experts are here to help navigate the challenges and optimize all production processes.