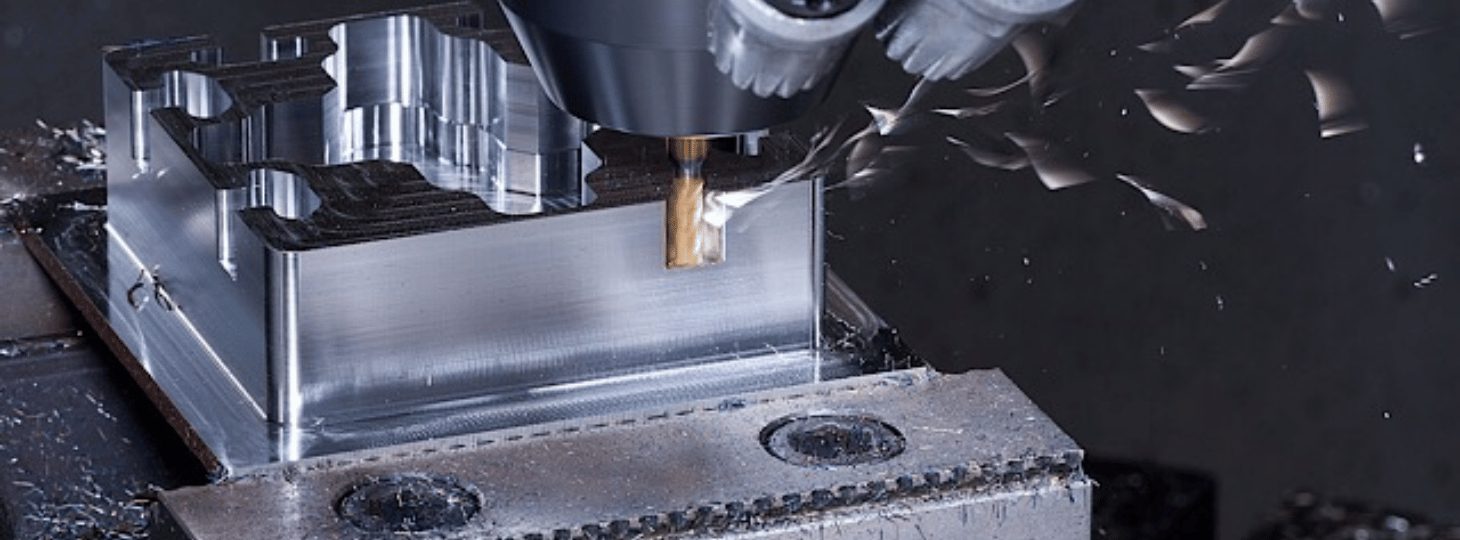

Customizing Business

3D printing allows manufacturers like Suproto, to create customized prototypes swiftly and economically. This speeds up the development process and encourages creativity, as businesses can experiment with different designs without worrying about high manufacturing costs.

Consumer Goods Industry

In the consumer goods industry, 3D printing empowers businesses to offer a range of personalized products. This can result in better customer engagement, fostering a stronger connection between the brand and the consumer.

Medical Industry

In healthcare, 3D printing is used to create tailored medical implants such as dental fixtures and prosthetic limbs, enhancing patient outcomes and satisfaction. According to NIH, 3D printing technology has been widely used in the field of implantable medical devices in recent decades because of its advantages in high precision, complex structure, and high material utilization.