01

Expertise in Swiss Machining

A key factor to consider when choosing a Swiss machining service is the expertise and experience. Skilled machinists who understand the intricacies of CNC Swiss precision machining are invaluable. They bring a depth of knowledge and experience that can save both time and money, by avoiding mistakes and ensuring efficient production.

02

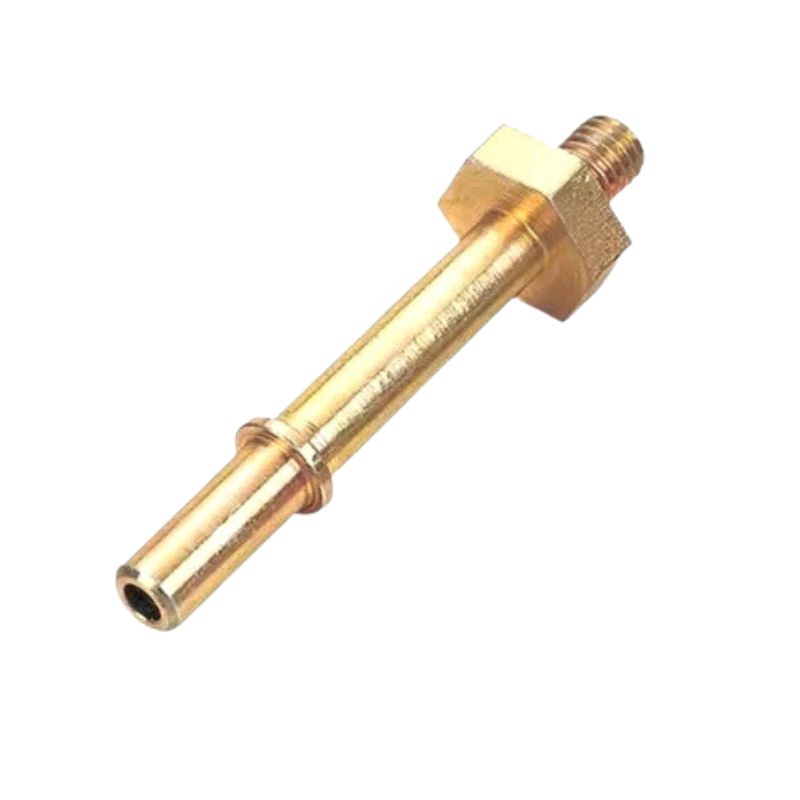

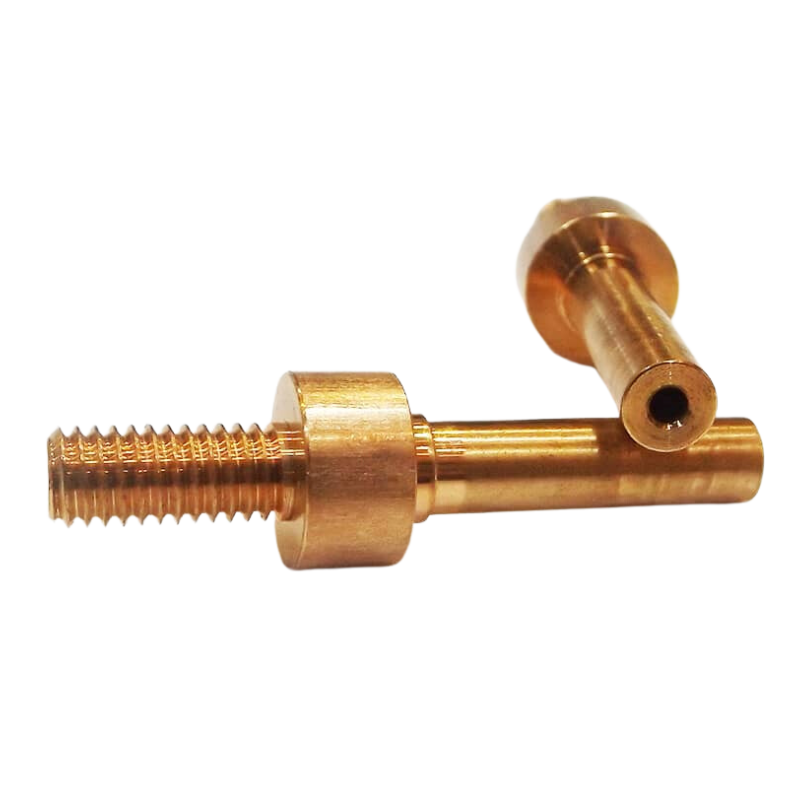

Capability to Handle Complexity

Swiss machining is known for its ability to handle complex geometries and tight tolerances. For instance, it's essential to ensure that the service that is chosen is capable of meeting the project's specific demands. This includes having the right equipment, software, and skilled personnel to handle complex jobs.

03

Scalability and Volume

According to an article in Ricardo, scaling up production is an integral part of the manufacturing process. Swiss machining, with its emphasis on precision, shouldn't mean sacrificing scalability. Once programmed, CNC Swiss machines can produce large volumes of identical parts, but it's crucial that the service anyone chooses has enough capacity to meet the project's requirements.

04

Quality Assurance

Quality assurance is vital in Swiss machining. When evaluating potential machining services, I suggest understanding their quality control protocols and compliance with internationally recognized standards such as ISO 9001. Suproto's dedicated quality assurance team, armed with cutting-edge inspection technology and tools, maintains precision in every stage of the machining process.