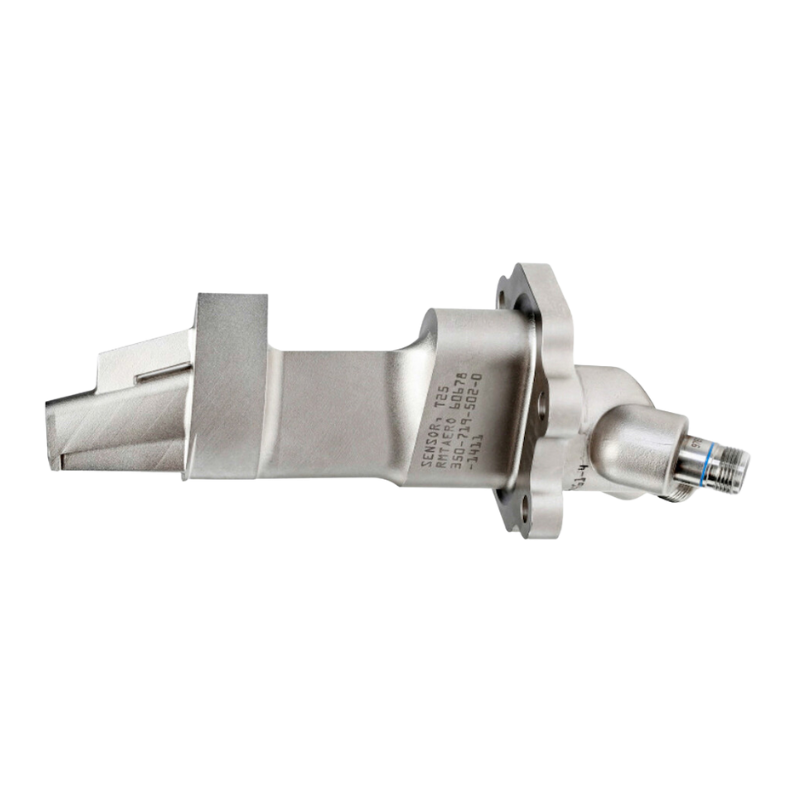

#1 Compatible Selection

Ensure that the 3D printing service to choose from offers a range of materials compatible with aerospace applications. Materials such as Titanium, Inconel, and high-performance polymers are often used in aerospace. Their ability to withstand high temperatures and pressures is crucial.

#2 Certifications

Check if the service provider holds relevant certifications like AS9100, which is specific to the aerospace industry. Compliance with industry standards ensures the production of high-quality 3D printed aerospace parts.

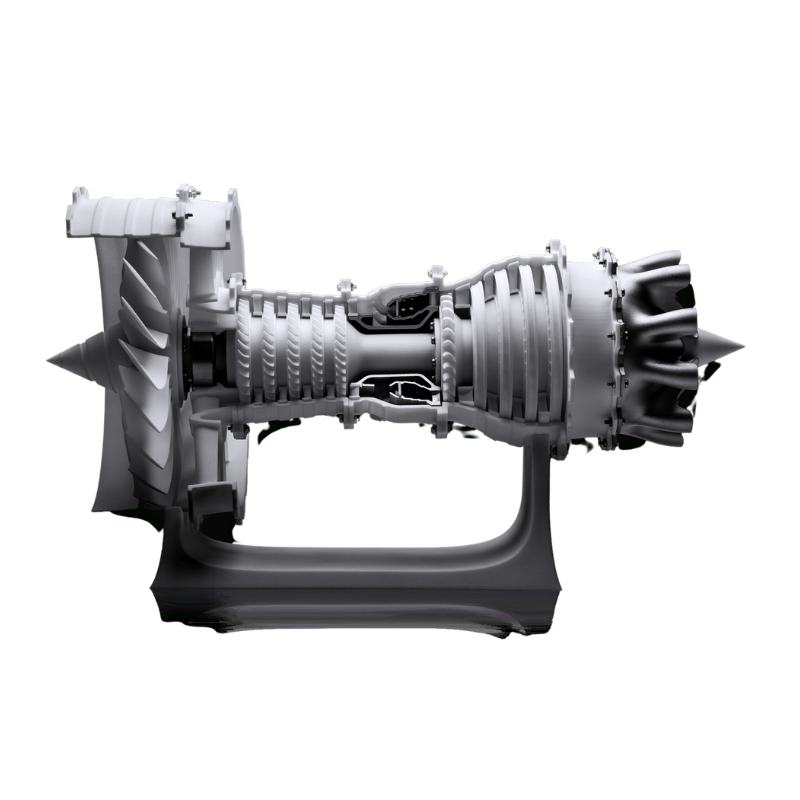

#3 Technological Expertise

Investigate the technological capabilities of the service provider. For example, Direct Metal Laser Sintering (DMLS) is a popular technology for producing metal aerospace components. At Suproto, we ensure that we are well-versed in the latest technologies and can cater to business-specific needs.

#4 Production Volume

For me, it is necessary to assess the service provider’s ability to handle the production volume. Whether the requirement is small-batch production or large-scale manufacturing, it is important that the service can scale according to the client’s needs.

#5 Quality Control

Consider the post-processing capabilities and quality control measures in place. Aerospace components often require finishing processes such as heat treatments or surface polishing to meet industry standards. For example, ensuring that the 3D printing service has stringent quality control measures is essential for producing reliable and durable components.