As the world moves towards more sophisticated manufacturing methods, the nickel alloy market is projected to grow from $12.14 billion – $14.68 billion (USD) from 2017-2022, reported by Corrotherm International. With the numerous advantages of using Inconel for 3D printing, it is vital to weigh certain considerations before choosing a service. Below are the ff:

#1 Material Knowledge

Deep understanding of Inconel as a material is critical. As stated by Mark Forged, inconel, a nickel-based superalloy, is highly resistant to corrosion and high temperatures, and it retains strength even after multiple heat cycles. Therefore, the chosen service provider should have profound knowledge about the material, its properties, and how to handle it during the 3D printing process.

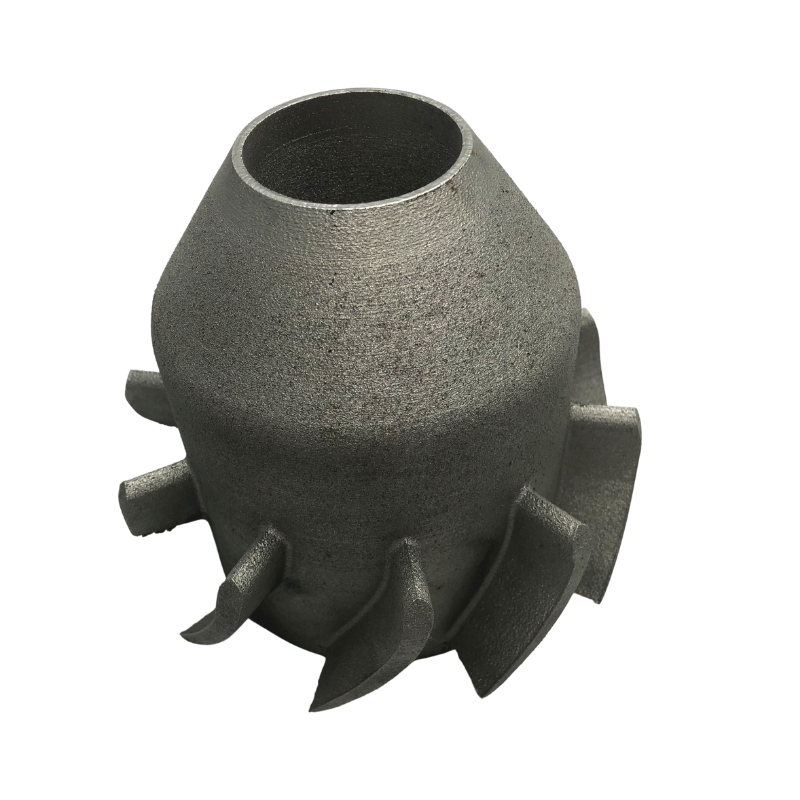

#2 Design Capabilities

The design capability of the service provider is a significant factor. Inconel 3D printing allows for intricate, one-of-a-kind part fabrication, and the service provider should have the skills to maximize these capabilities without compromising the end product’s desired aesthetics and performance.

#3 Heat Control

When 3D printing with Inconel, it’s important to control heat warps that occur during the melting and solidifying of powder layers. So, consider choosing a service provider who understands and demonstrates the ability to efficiently manage the heating process, crucial for maintaining dimensional tolerance in the printed parts.

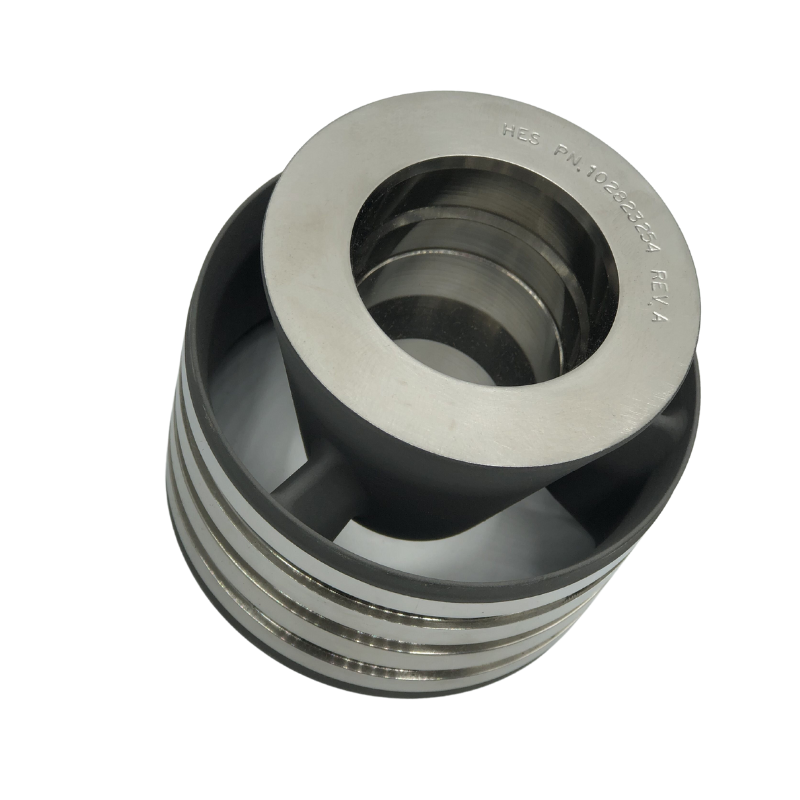

#4 Minimum Wall Thickness

The minimum wall thickness plays a significant role in determining the strength and functionality of a 3D printed part. Depending on the grade of Inconel used, the minimum wall thickness for 3D printed Inconel parts can vary, making it a vital factor to consider that every service provider should focus.

#5 Production Cost

Inconel is traditionally an expensive material. Nevertheless, 3D printing offers a cost-effective alternative due to its material efficiency. Therefore, opt for a service like Suproto that provides an economical solution without compromising on quality. Keep in mind that the decision to choose an Inconel 3D printing service requires thorough research and a holistic understanding of the project’s specific needs.