High Strength-to-Weight Ratio

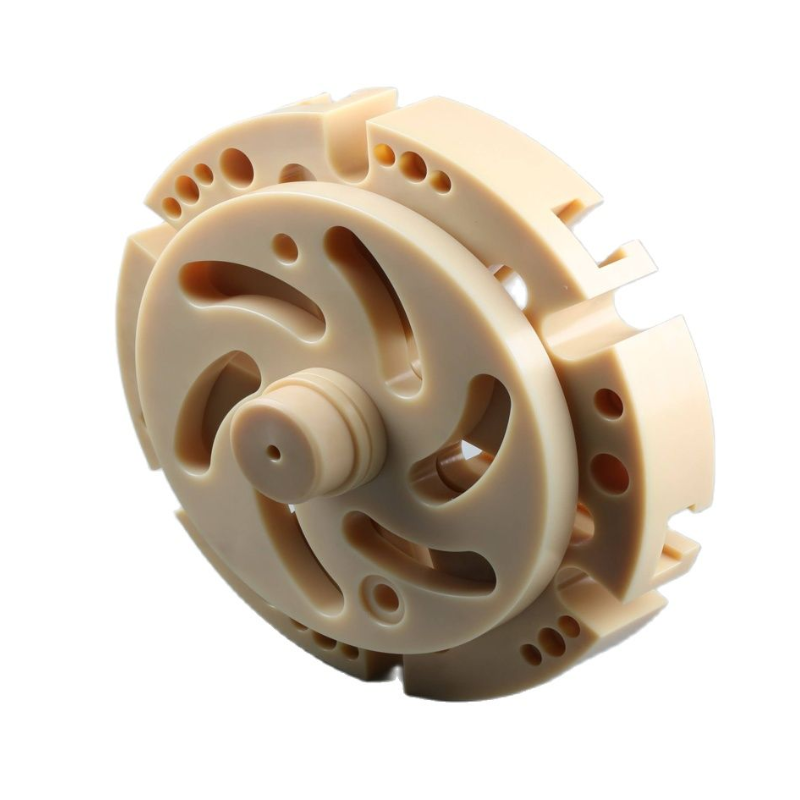

HDPE is renowned for its impressive strength-to-weight ratio. This characteristic ensures that the components machined from HDPE are robust yet lightweight, providing a balance between durability and portability. Suproto’s CNC machining HDPE service produces a lightweight, moisture-resistant part for a marine application.

Chemical and Moisture Resistance

HDPE has excellent resistance to both chemicals and moisture. This allows for machining HDPE into parts that are exposed to various chemicals or moisture-prone environments, extending their lifespan and reducing maintenance.

Excellent Machinability

According to Polyalto, high-density polyethylene (HDPE) can easily be machined or welded, which makes it possible to design larger projects, such as large watertight tank liners used to store important volumes of liquids. This allows the material to be worked easily and efficiently using CNC machines, resulting in high-quality HDPE parts.

Good Electrical Insulator

As an excellent electrical insulator, HDPE is ideally suited for applications where electrical conductivity could be a concern. This increases the safety and reliability of HDPE components in electrical applications. HDPE has a low friction coefficient, allowing for smooth movement when used in applications requiring sliding or rotating components.