Precision

One of the main features of custom parts machining is its high precision. Utilizing advanced technology, machinery can produce parts with extreme accuracy, down to even the smallest dimensions. This exactness ensures components perfectly fit their intended applications.

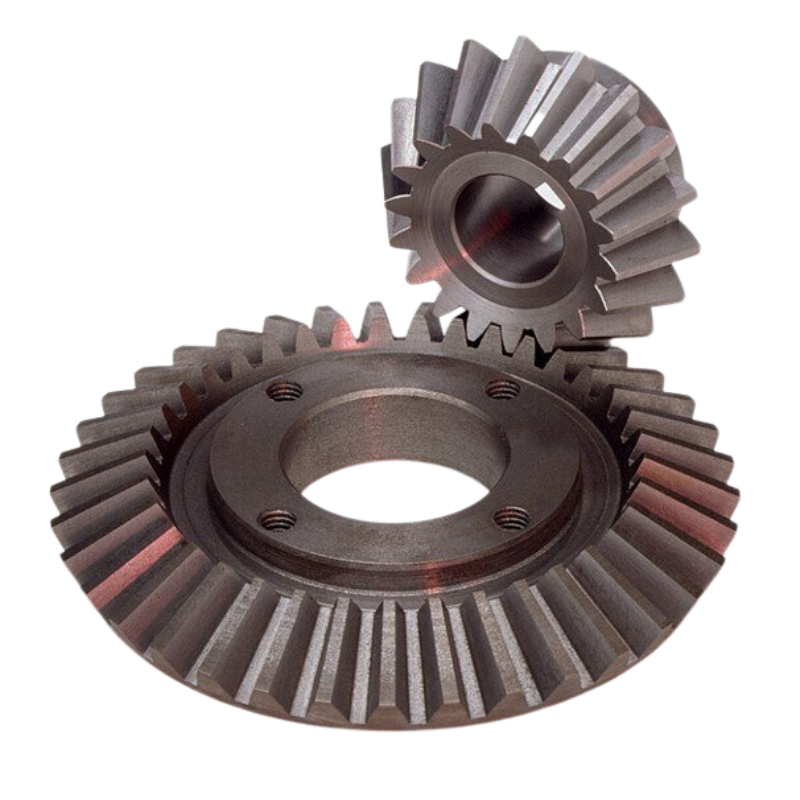

Versatility

With cnc custom parts machining, the range of parts that can be created is virtually limitless. The machinery can handle various materials and produce a diverse array of parts, from simple shapes to complex geometries.

Speed

Custom parts machining significantly cuts down on production time. Automated processes, coupled with the capability to run operations around the clock, result in faster turnarounds and higher output.

Consistency

One of the key strengths of custom parts machining is its ability to produce identical parts, even across large production runs. This consistency ensures every part meets the exact specifications without deviations. Suproto’s state-of-the-art facilities and dedicated teams have become a trusted name in the custom parts machining sphere.

Customizability

Perhaps the most defining feature, cnc custom parts machining allows for a high level of customization. Parts can be tailored to meet specific requirements, which can be critical in industries like aerospace or healthcare, where custom solutions are often needed.