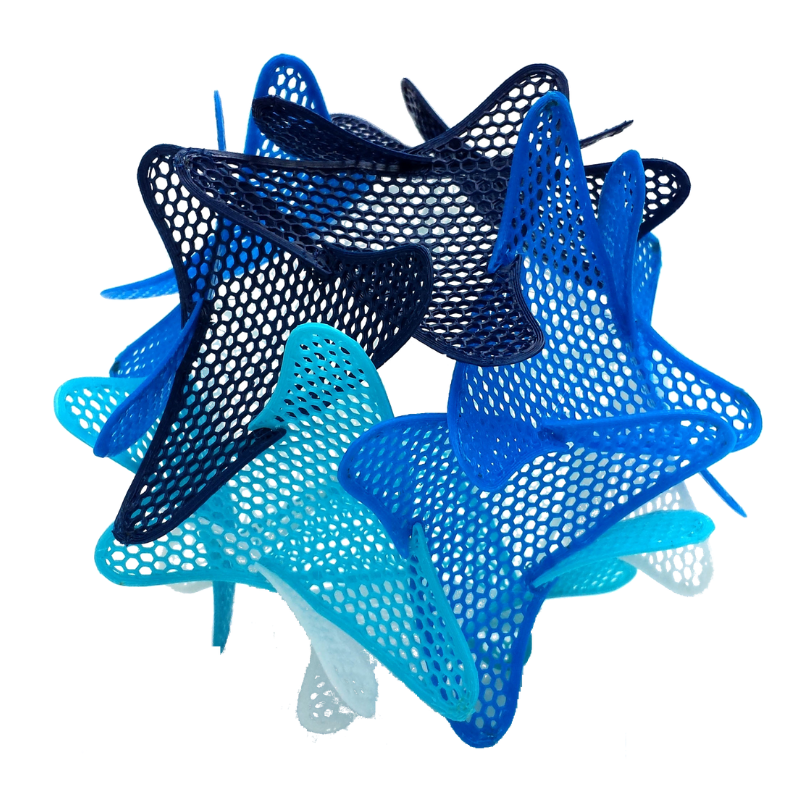

Wide Range of Material Compatibility

One of the main attractions of FDM 3D printing is its wide compatibility with numerous materials. Thermoplastics such as ABS, PLA, Nylon, and others can be used in the FDM process. Speaking from experience, this provides businesses with a considerable level of flexibility in product design and functionality, fulfilling their specific needs.

Economical Manufacturing Solution

Suproto’s FDM technology, along with its 3D printing service, stands out for its cost-effectiveness. Its operational simplicity means that the maintenance and operational costs are relatively low, making it an ideal solution for businesses looking to minimize production expenses without sacrificing the quality of output.

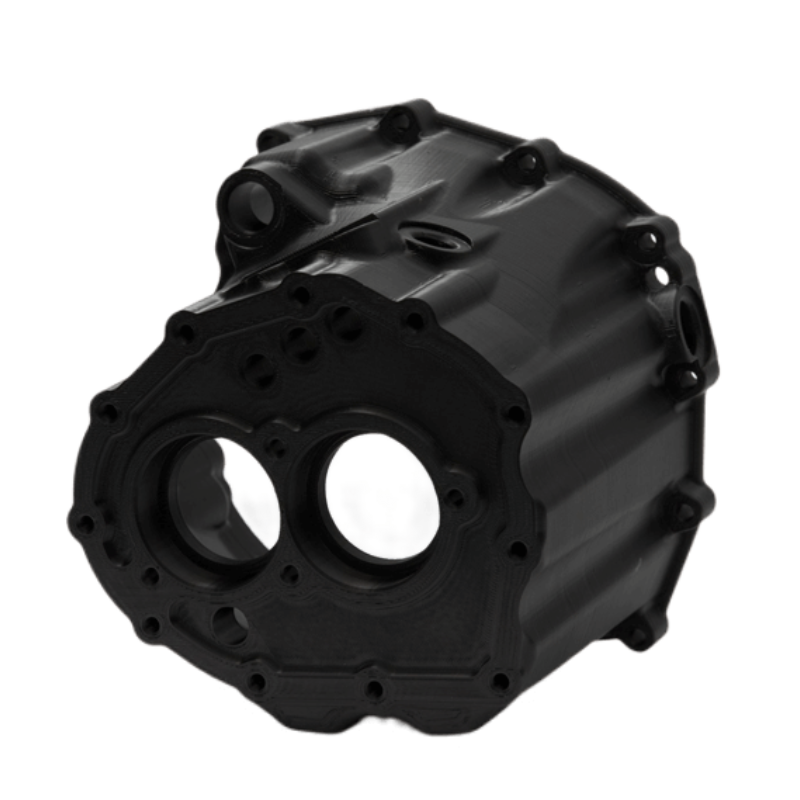

Rapid Prototyping

FDM 3D printing enables rapid prototyping, an essential aspect of modern manufacturing processes. Businesses can swiftly transform their concepts into tangible prototypes, helping to shorten the development cycle, enhance design precision, and streamline the overall production process.