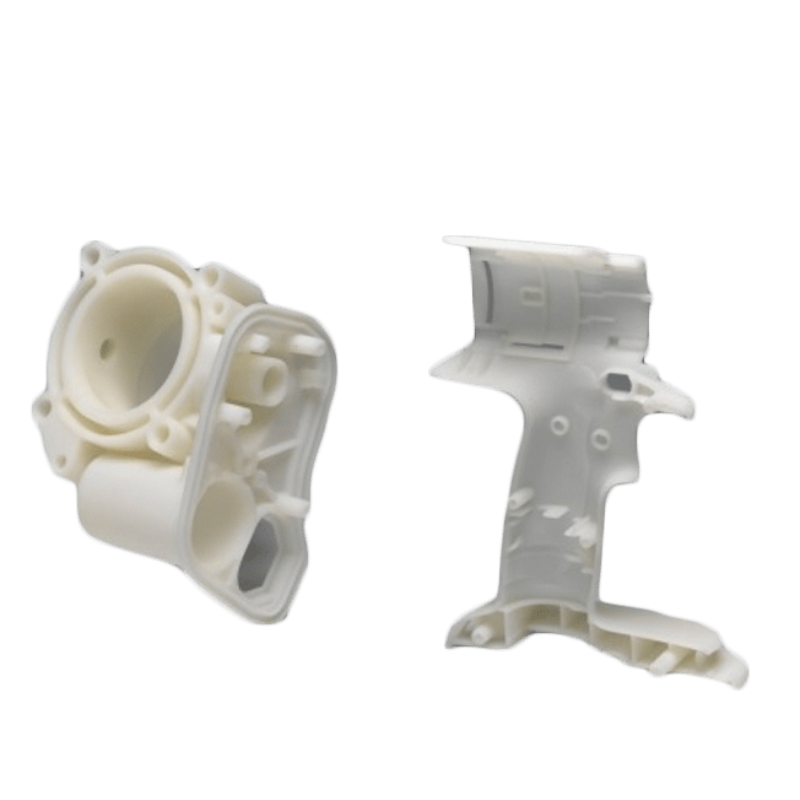

High Resolution and Accuracy

SLA printing service provides a superior level of precision compared to other 3D printing technologies. This allows the production of parts with intricate details and complex geometries. Due to technology’s accuracy, it’s extensively used in industries where precision is crucial, such as aerospace and medical sectors.

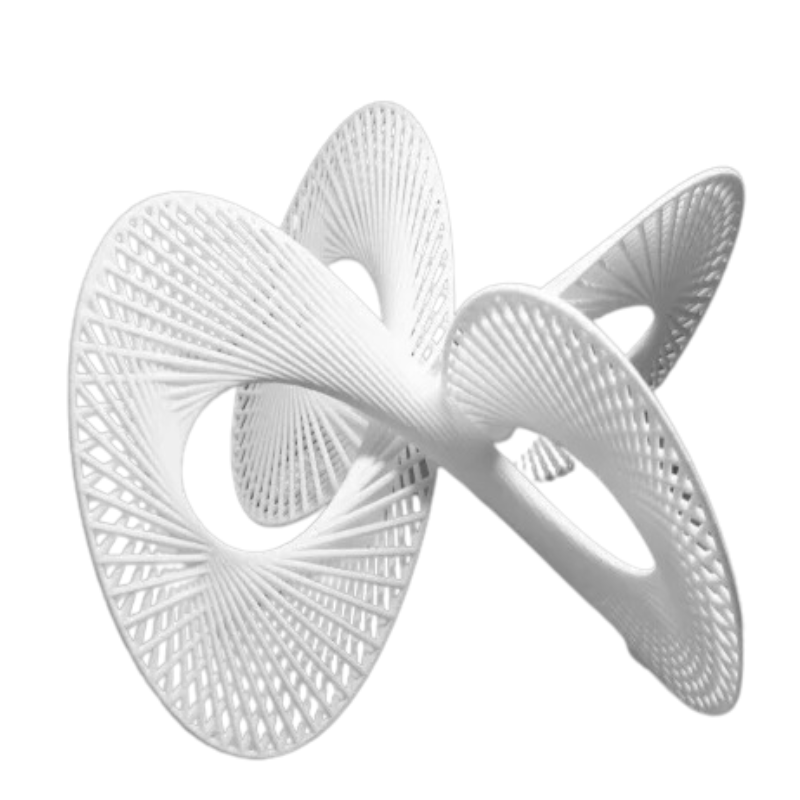

Smooth Surface Finish

One of the key benefits of SLA printing is the smooth surface finish of the produced parts. This quality makes SLA 3D printing ideal for creating aesthetic models, prototypes, and end-use parts that require minimal post-processing.

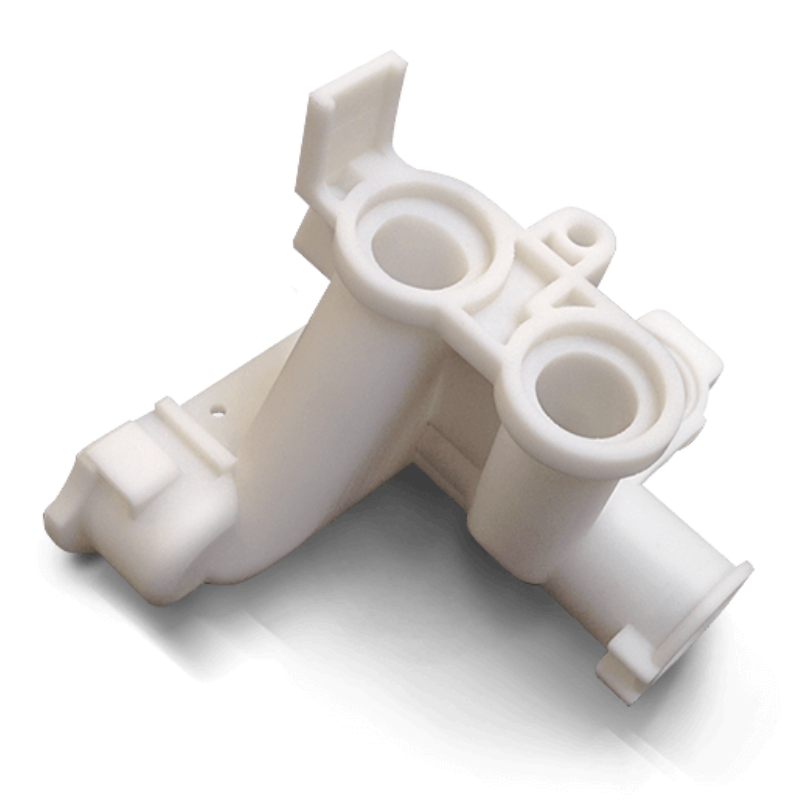

Variety of Material Choices

SLA printing offers a wide range of material choices to users. From rigid to flexible, clear to opaque, and standard to high-temperature resistance, the versatility in material selection caters to different industry needs. For example, a company that produces custom parts can utilize SLA 3D printing services quickly and accurately produce high-quality prototypes or final parts.

Isotropy

SLA 3D printing produces highly isotropic parts. This means that the parts have uniform properties in all directions-a characteristic essential in many engineering applications. From my own perspective, this ensures reliable performance and quality in various engineering applications.

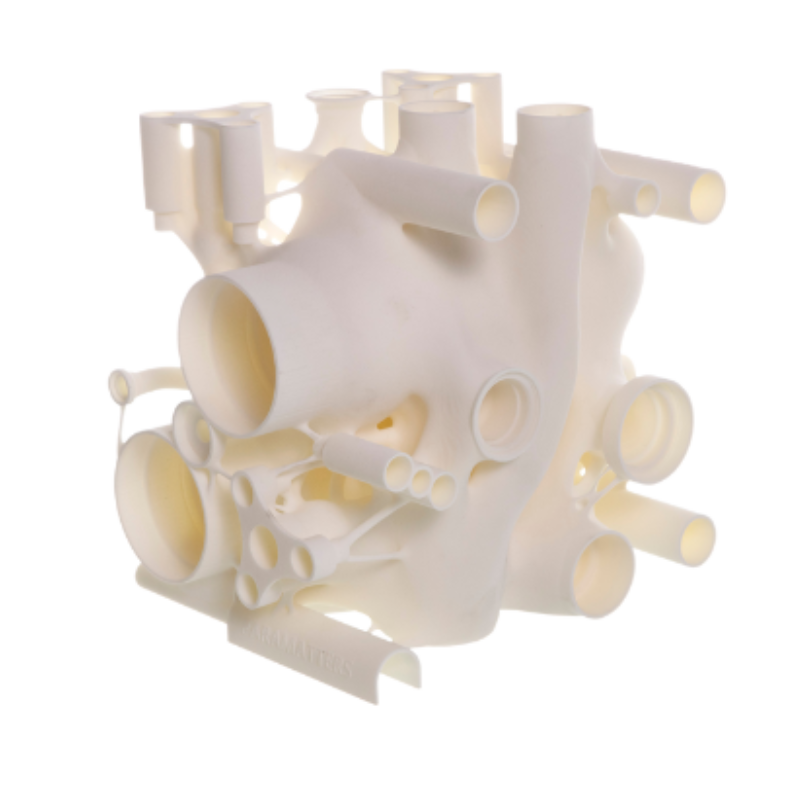

Watertightness

SLA printed parts and prototypes have continuous surfaces, ensuring they are watertight. This feature, combined with 3D printing service from Suproto’s high-quality printing process, makes it ideal for applications involving fluid or airflow, such as microfluidic devices or fluidic connectors.