Have you imagined having a groundbreaking idea for a product that can change the world? The crucial step – prototyping – is where many innovations falter. However, as the development wheels start turning, countless obstacles and unforeseen issues start piling up, but the story doesn’t have to end this way.

Here is the game-changing approach that can save the day – rapid prototyping. It involves creating a simplified version of a product to test its concept, gather feedback, and make improvements. Furthermore, in this article, I will delve into the nuances of rapid prototyping, the strategies to employ, and the plethora of benefits it brings to product development.

Ready to turn every product idea into a market sensation? Read on!

1. Brief Overview of Rapid Prototyping

Rapid prototyping is a design workflow essential in product development that involves swiftly creating prototypes to test design solutions with users and stakeholders. Employing automated technologies such as 3D printing and CNC machining facilitates the creation of physical models at an accelerated pace. I believe the importance of rapid prototyping lies in its capacity to gather user feedback early in every design process.

2. The Evolution of Rapid Prototyping

From humble beginnings with basic handmade models to state-of-the-art 3D printing and CAD software, rapid prototyping has undergone a phenomenal transformation. Let’s explore its captivating journey.

Early Beginnings

In the 19th century, the genesis of rapid prototyping can be traced back to topography and photosculpture techniques. Though labor-intensive, these processes laid the groundwork for what we now recognize as rapid prototyping. I have seen topography use contours to create relief maps, and photosculpture involved capturing 3D shapes using photographs, both of which were a prelude to modern 3D printing.

Middle Ages

The 1980s marked the middle era in the development of rapid prototyping. During this period, Hideo Kodama from Japan and Charles Hull, often regarded as the father of modern rapid prototyping, from the USA were instrumental in the progress. They described and developed the first machines capable of 3D printing. Hull, for example, patented an apparatus for producing three-dimensional objects by stereolithography in 1984.

Present

Rapid Prototyping has grown phenomenally since the 1980s, embracing advancements in computer technology to evolve into agile and robust forms. From holographic printers to integration with CAD (Computer-Aided Design), its applications are diverse and transformative. Then it hit me, that the different sector is leveraging rapid prototyping to expedite product development cycles and enhance customization today.

3. Advantages of Rapid Prototyping

Rapid prototyping is not just fast; it’s a smart and efficient way to innovate. Delve into the manifold advantages, from boosting creativity to fostering collaboration. Here are some to explore:

Accelerated Product Development

First and foremost, one of the pivotal advantages of rapid prototyping is the acceleration of product development. By creating prototypes quickly and efficiently, companies and product teams can validate their ideas and designs with users at an early stage. Consequently, this iterative process allows for swift improvements based on user feedback, thus significantly reducing the time it takes to develop a final product.

Enhanced Creativity and Innovation

I have seen how rapid prototyping paves the way for a surge in creativity and innovation. Essentially, this approach permits designers to experiment with different concepts and ideas without incurring exorbitant costs. It grants the freedom to explore diverse solutions and adapt based on user reactions, thereby fostering a culture of innovation.

Reduced Costs and Risks

Furthermore, another substantial advantage of rapid prototyping is the reduction in costs and risks. Since this method facilitates early detection of design flaws, it consequently minimizes the risk of costly errors down the line. Also, I believe, by receiving user feedback during the initial stages, companies can avert potential issues that might have emerged after the product launch.

4. Types of Rapid Prototyping

Discover the diverse types of rapid prototyping methods, from traditional physical models to digital simulations. Whether in manufacturing or web development, learn which method aligns best with goals. Here are some to take note of:

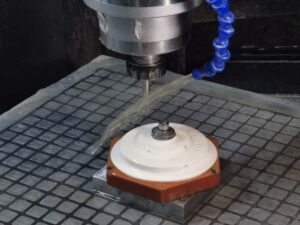

Subtractive Prototyping

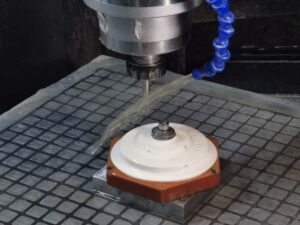

Delving into the various types of rapid prototyping, let’s start with subtractive prototyping. Essentially, this method involves removing material from a block or sheet to create the desired shape. Common techniques include milling, cutting, and drilling. Subtractive prototyping is particularly useful for creating prototypes out of materials that closely resemble the final product, thereby ensuring a high degree of accuracy and finish.

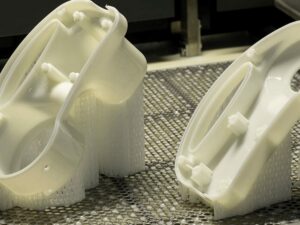

Additive Prototyping

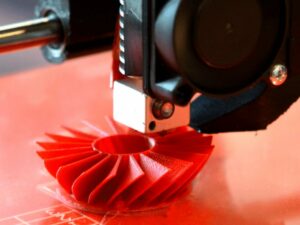

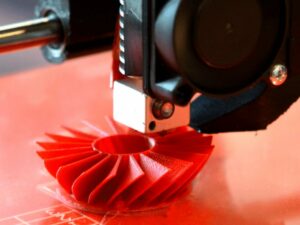

Next up is additive prototyping, which is also known as 3D printing. Unlike subtractive prototyping, this process involves building objects by adding material layer by layer. This method allows for the creation of complex geometries and forms that would be difficult or impossible to achieve with subtractive methods. I always take note of this: 3D printing is a subset of additive prototyping.

Virtual Prototyping

Now, virtual prototyping involves creating digital models of the product instead of physical ones. This is especially beneficial in the early stages of product development as it allows for rapid iterations and evaluations without the need for physical materials. I see virtual prototyping is widely used for testing functionality, analyzing performance, and visualizing designs before moving on to the creation of physical prototypes.

5. Materials Used in Rapid Prototyping

Understanding how the choice of materials can impact not only the prototype’s functionality but also its cost, on the project’s specific requirements is crucial. Here are a few to consider:

Plastics and Polymers

First and foremost, plastics and polymers play an instrumental role in rapid prototyping. According to a study, one of the significant benefits of additive manufacturing, often referred to as 3D printing, is the freedom of design it offers, which is particularly advantageous when using plastics and polymers. I can tell, these materials are notable for their flexibility and ease of molding into intricate shapes.

Metals

Secondly, metals are also highly utilized in rapid prototyping. They are characterized by high thermal and electrical conductivity and are strong yet deformable under applied mechanical loads. This makes them indispensable in industries such as aerospace, where the strength and durability of materials are paramount.

Ceramics

Furthermore, ceramics are a cornerstone in the realm of rapid prototyping. These materials are inorganic compounds, usually made of oxides, carbides, nitrides, or silicates of metals, and are characterized by very high strength under compression and low ductility. As a ceramics enthusiast myself, I have seen at Suproto how the intricate nature of ceramics has led to revolutionary applications in biomedical implants and aerospace.

Composites

As per ScienceDirect, rapid prototyping technology has given rise to the development of application-oriented composites through processes such as Selective Laser Sintering/Melting, Laser Engineered Net Shaping, and Fused Deposition Modeling. These materials are essentially made by combining two or more distinct materials to exploit their best properties.

6. Rapid Prototyping Technologies

With the advent of 3D printing and advanced CAD software, here we unravel the various technologies available today. Learn how these technologies empower designers to create detailed and functional prototypes with unprecedented speed and precision.

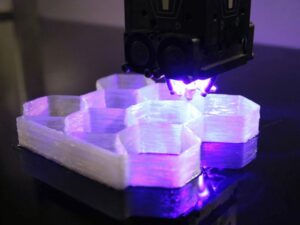

3D Printing

I can imagine a wizard conjuring objects out of thin air with 3D printing – modern-day sorcery turning digital dreams into tangible realities. Through this bewitching process, a cascade of materials is layered with microscopic precision, as directed by a digital 3D model, breathing life into intricate and fantastical designs.

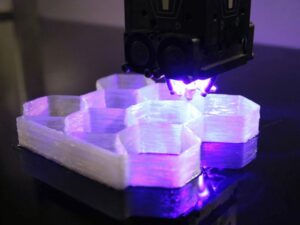

Commonly referred to as SLA, stereolithography is one of the earliest forms of 3D printing technologies that surfaced in the 1980s. The process of SLA involves the use of an ultraviolet laser which is aimed at a vat of photopolymer resin, solidifying the material layer by layer to create detailed and high-resolution objects. Unquestionably, the fine quality of surface finish makes SLA an ideal choice for creating cosmetic prototypes.

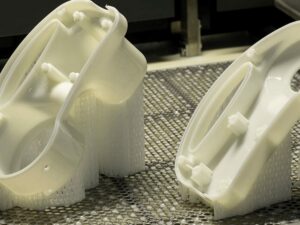

- Selective Laser Sintering (SLS)

Selective Laser Sintering, or SLS, is another additive manufacturing technology where a laser sinters powdered material, typically nylon or polyamide, binds it together to create a solid structure. Unlike SLA, SLS does not require support structures, as the powder acts as a support for the layers. This permits more complex geometries to be printed and enables the production of highly durable parts.

- Fused Deposition Modeling (FDM)

Shifting gears, let’s talk about Fused Deposition Modeling (FDM). It is an additive manufacturing technique that is especially popular among hobbyists. This process involves the melting and extrusion of a thermoplastic filament, which is deposited layer by layer to build the object. However, FDM is not the best option for highly detailed or complex structures as the resolution is comparatively lower than SLA or SLS.

Computer Numerical Control (CNC) Machining

CNC Machining is not an additive but a subtractive manufacturing process, which involves removing material from a solid block using various cutting tools. This process is primarily used for creating prototypes and parts from metals or plastics. Now I see this important, although it’s highly effective, CNC Machining usually requires more time and is often more expensive compared to additive manufacturing processes like 3D printing.

Software for Virtual Prototyping

The cornerstone of rapid prototyping technologies is the software used for virtual prototyping. This software allows designers and engineers to create, test, and optimize designs in a virtual environment before manufacturing physical prototypes. The employment of virtual prototyping software has been a game-changer in product development, allowing for quicker turnarounds and more effective design processes.

7. Rapid Prototyping in Various Industries

Rapid prototyping is the unsung hero behind countless innovations across industries. Take a tour through diverse sectors and witness how rapid prototyping is revolutionizing product development and shaping the future.

Medical and Biotech

In the realm of medical and biotech, rapid prototyping has been nothing short of revolutionary. Customized patient-specific implants, surgical planning models, and even bioprinting of tissues are some astonishing applications in this sector. Interestingly, Suproto has been pioneering the use of 3D printing for producing surgical guides, which significantly reduces operating times and increases surgical precision.

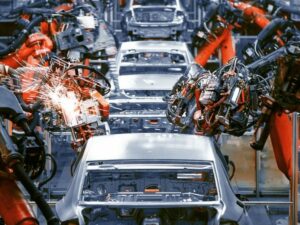

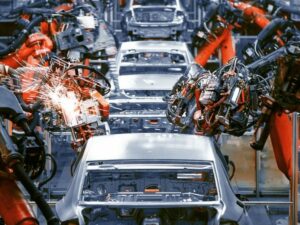

Automotive

Rapid prototyping in the automotive industry has been a driving force behind the accelerated development of new models and custom components. The ability to swiftly produce prototypes for parts testing, design validation, and even end-use components has reduced product development cycles significantly.

Aerospace

In the aerospace industry, the stakes are incredibly high, and there is no room for error. With rapid prototyping, engineers are able to create intricate, lightweight components, and even parts for small-scale production. One of the noteworthy achievements is the development of complex, lightweight structures that were previously impossible or too costly to manufacture using traditional methods.

Consumer Electronics

The consumer electronics sector thrives on innovation and quick turnarounds. Rapid prototyping here facilitates the swift development of casings, components, and even entire products for market testing and feedback. I suppose it’s particularly helpful in highly competitive markets where getting a product to the consumers before the competition is essential.

8. Challenges in Rapid Prototyping

While rapid prototyping is a formidable tool in product development, it’s not without its hurdles. This section sheds light on the various challenges and offers insights on how to navigate these challenges to effectively harness the full potential of rapid prototyping. See the ff below:

Technical Difficulties and Limitations

Despite the marvels of rapid prototyping, technical challenges abound. One of the major issues lies in the limitations of the technologies themselves; certain methods may not be suitable for particular materials or geometries. I can tell that achieving the desired levels of tolerance and finish can be challenging.

Material Selection and Availability

Material selection is pivotal in rapid prototyping and comes with its own set of challenges. The availability of materials compatible with certain rapid prototyping technologies may be limited, and finding the right material with the desired properties can be daunting.

Cost Constraints

Cost is often a considerable barrier to the implementation of rapid prototyping. While prices have been decreasing over the years, the initial investment in equipment and materials can still be substantial, especially for small businesses or startups. I can vouch, Suproto, for example, offers consultation services to help businesses optimize their designs for manufacturability and cost-effectiveness.

The following table outlines the challenges in rapid prototyping, including technical difficulties, material selection and availability, and cost constraints, along with potential solutions to overcome these obstacles.

| Challenges |

Description |

Possible Solutions |

| Technical Difficulties |

Rapid prototyping technologies may have limitations that make them unsuitable for certain materials or geometries. Achieving the desired levels of tolerance and finish can be challenging. |

– Research and select appropriate rapid prototyping technologies for specific requirements. – Work closely with experts and technicians to optimize designs and overcome technical limitations. |

| Material Selection |

Material selection is crucial in rapid prototyping, but finding the right material with desired properties can be daunting. The availability of materials compatible with certain rapid prototyping technologies may also be limited. |

– Conduct thorough research on available materials and their compatibility with rapid prototyping technologies. – Explore alternative materials or techniques to achieve desired properties. – Collaborate with material suppliers to expand the range of available options. |

| Cost Constraints |

The initial investment in equipment and materials for rapid prototyping can be substantial, especially for small businesses or startups. While prices have decreased, cost remains a significant barrier to implementation. |

– Evaluate the return on investment (ROI) and long-term benefits of rapid prototyping for the business. – Consider outsourcing rapid prototyping services to reduce upfront costs. – Optimize designs for manufacturability and cost-effectiveness through consultation services or collaborations with experts. – Explore grants, funding options, or partnerships to offset the initial investment. |

Conclusion

Throughout our deep dive into the world of rapid prototyping, we’ve witnessed its remarkable evolution, versatile applications, and its ability to accelerate design timelines and foster innovation. Now, it’s time to think, “How could the business leverage rapid prototyping to efficiently explore, validate, and refine the next groundbreaking product or feature?”

As business innovators, it’s crucial to stay ahead. Pondering over the potential of rapid prototyping for the business, or needing insights to chart the prototyping journey, we’re here to help. Reach out to us and let’s embark on a transformative collaboration. The innovation awaits – contact us now!