#1 Quality Assurance

Making certain that the fabricator has the capacity to produce and deliver products that align with the unique specifications and maintain the highest quality standards is absolutely vital. This doesn’t merely entail the fabricator’s ability to craft pieces that visually match the expectations. Adhere to strict quality control procedures to guarantee client satisfaction.

#2 Technical Capabilities

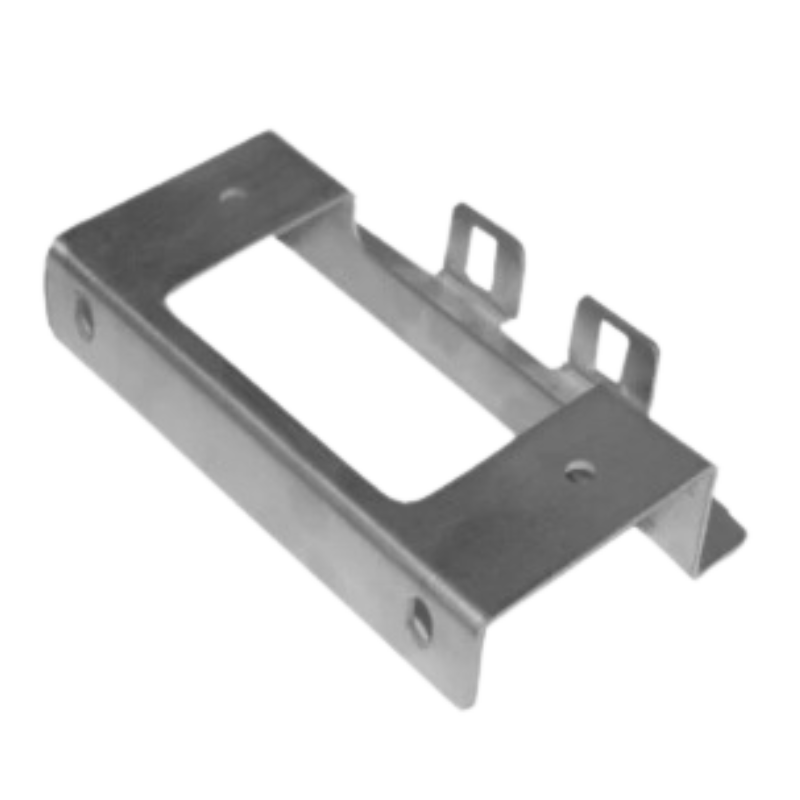

The technical capabilities of a fabricator, vital for project success, extend beyond advanced machinery. They encapsulate a skilled workforce, deep knowledge of diverse materials, and a capacity for tackling unique project requirements. For instance, the fabricator should be able to handle the specific type of metal that the project requires.

#3 Industry Experience

Choosing a fabricator with proven industry experience is essential. Their tenure represents not just years in business, but a wide-ranging knowledge base, derived from managing diverse projects and overcoming numerous challenges. Fabricators with a long track record, like Suprotos, often bring invaluable insights and knowledge.

#4 Turnaround Time

Timely delivery is essential for keeping the project on schedule. According to Hollingsworth, a compelling study revealed a significant trend among consumers that cannot be ignored: approximately 69% of shoppers expressed that they would be much less inclined, or even unlikely, to patronize a retailer in the future if an item they bought was not delivered within two days of the promised date.

#5 Communication

Effective and transparent communication with the fabricator plays a crucial role. Building a strong partnership with a fabricator who understands the vision and requirements is essential. Here’s why that’s important, for it to establish a relationship where the ideas and expectations are not only acknowledged but truly understood and transformed into reality.