Do you know what keeps our cars, boats, and industrial machinery running smoothly? It’s a critical component known as the transmission shaft. However, a lack of proper understanding of these shafts and their maintenance can lead to serious issues in equipment operation, performance, and longevity.

In this article, we are taking a detailed look at transmission shafts – their construction, types, applications, and much more. You must be wondering… This deep dive is specifically crafted to provide business owners and entrepreneurs with a comprehensive understanding of these vital mechanical components.

So, are you ready to gear up your knowledge about transmission shafts? Let’s dive straight into this topic.

1. Understanding Transmission Shafts

Transmission shafts transmit rotational movement and are vital components in mechanical systems. They are meticulously designed and engineered to endure high torque and vibrations. But there’s a catch, by effectively transferring rotational energy, transmission shafts play a pivotal role in facilitating the smooth and efficient operation of machinery, ensuring optimal performance and productivity.

Personally speaking, the importance of understanding these components cannot be overstated. They play a crucial role in the performance and efficiency of various machines, from cars to industrial equipment.

2. How a Transmission Shaft Works

The transmission shaft’s key role is to facilitate the transfer of rotational energy and torque from the engine to the wheels or other machinery components, serving as the linchpin of the power transmission process. Let’s delve into this intricate procedure, dissecting it into three straightforward phases.

Torque Generation

The engine, acting as a powerful heart, generates a dynamic force recognized as torque. This torque is then skillfully channeled via the transmission shaft, a critical conduit in the machinery. Now, this is important… This strategic transfer of torque ignites the key propulsion mechanism, sparking movement and operational effectiveness in vehicles or complex machinery.

Speed Regulation

Operating in perfect synchrony with the gearbox, the transmission shaft expertly manages the speed of rotation, channeling it efficiently toward the wheels or other kinetic components. For instance, consider a high-performance car shifting into higher gears. Here, the transmission shaft’s role in modulating the speed of rotation to the wheels becomes critical, ultimately defining the vehicle’s top speed and efficiency.

Direction Control

In specific scenarios, transmission shafts showcase their versatility by regulating the direction of rotation, thereby facilitating not just forward, but also reverse motion. This maneuverability aspect underscores their critical role in diverse operational dynamics. Here’s why that’s important… Understanding the working mechanism of transmission shafts can significantly improve maintenance and troubleshooting practices.

3. Key Features of Transmission Shafts

Crafted with a keen eye for detail, transmission shafts incorporate distinct features to meet the exacting demands of varied applications. Key attributes encompass:

Torque Transmission

The quintessential role of a transmission shaft is encapsulated in its capacity to handle and channel the torque, meticulously crafted by the engine, toward the wheels or other kinetic components. Here’s the bottom line… The transmission shaft’s design and purpose play a crucial role in converting engine-generated torque into motion, driving the operational effectiveness of vehicles or complex machinery.

Flexibility and Vibration Reduction

Crafted with meticulous attention to flexibility, transmission shafts excel in absorbing and dampening vibrations. And the best part is… This ability not only ensures seamless operation but also significantly reduces wear on interconnected components, safeguarding the overall system’s longevity and performance. As a transmission shaft manufacturer, we prioritize key features to deliver reliable, high-performance products.

Durability and Strength

Fabricated from resilient materials such as steel, transmission shafts boast exceptional durability and fortitude. These stalwart components are designed to endure immense levels of stress, resist extreme heat, and withstand wear and tear, a testament to their hard-wearing construction. For example, the vibration reduction feature of transmission shafts contributes significantly to the longevity of other machinery components.

4. Types of Transmission Shafts

A diverse array of transmission shaft types exists, each meticulously designed to fulfill specific requirements within distinct mechanical systems.

Main Shaft

The main shaft acts as the core conduit, directly linking the engine and transmitting torque and rotational motion. As an integral part of the powertrain system, it efficiently transfers the engine’s force, propelling mechanical elements for smooth and controlled movement. Here’s the interesting part… The main shaft’s robust design and precise engineering optimize power transmission, enhancing the machinery’s performance.

Propeller Shaft

The propeller shaft serves as the intermediary, transferring power from the gearbox to the rear axle in rear-wheel-drive vehicles. Its crucial role enables the propulsion of the vehicle by effectively transmitting torque to the rear wheels. You guessed it… Engineered with precision and built to last, our propeller shafts ensure efficient and reliable power transmission, enhancing vehicle performance and maneuverability.

Counter Shaft

The countershaft may specifically refer to a shaft used in a manual transmission. Positioned parallel to the main shaft, it securely holds gears and rotates in the opposite direction, providing necessary gear reduction or overdrive functionality. The layshaft synchronizes with the main shaft for seamless gear shifting and precise speed and torque control, enhancing transmission system performance and versatility.

Lay Shaft

Layshaft lies in their specific applications within the transmission system. According to SAE International, a dynamic model has been developed for a layshaft-type geared rotor system. This model considers the interactions between three parallel rotating shafts and incorporates factors such as gear displacements and counter-shaft motions.

Output Shaft

The output shaft, as its name suggests, serves the crucial purpose of delivering power from the transmission to the other components of the machine. The output shaft acts as the crucial final link, transmitting rotational energy from the transmission to drive different mechanisms and enable machine operations. Suprotos excels in manufacturing all these types of transmission shafts, ensuring high quality and performance.

5. Materials Used for Transmission Shafts

The choice of construction material plays a critical role in determining the performance and durability of transmission shafts. Optimal material selection ensures that the shaft can withstand the mechanical stresses, torque loads, and environmental conditions it may encounter during operation. Below are the materials used:

Steel

Steel, the preferred material for transmission shafts, offers exceptional strength, durability, and resistance to wear and tear. Its robust nature allows shafts to endure demanding conditions, ensuring reliable performance over extended periods. Here’s something we can both agree on… Steel’s exceptional resistance to corrosion and remarkable thermal stability make it the ideal choice for manufacturers

Aluminum

In certain cases, transmission shafts are crafted from aluminum due to their advantageous lightweight properties. This material choice allows the shafts to achieve reduced mass, making them well-suited for high-speed applications where weight reduction is critical. Suprotos recognizes that aluminum’s lightweight nature plays a crucial role in improving acceleration, responsiveness, and fuel efficiency.

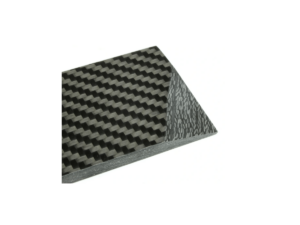

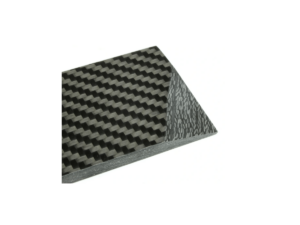

Carbon Fiber

The exceptional strength-to-weight ratio of carbon fiber makes it indispensable for high-performance applications. It allows the construction of transmission shafts that deliver exceptional performance without unnecessary weight. Now, this is important… Utilizing carbon fiber in manufacturing transmission shafts significantly reduces weight, enhancing performance and improving fuel efficiency.

6. Transmission Shafts in Different Industries

Transmission shafts assume a vital role as essential components in a wide range of industries, serving as integral components for the proper operation of various machines and vehicles. Without transmission shafts, the machinery and vehicles we rely on would be incapable of functioning optimally. Below are the following:

Automotive Industry

Transmission shafts play a crucial role in vehicles by transferring power from the engine to the wheels. As a vital component in the powertrain system, these shafts seamlessly transmit torque, converting engine power into forward motion at the wheels. So what’s my point? Transmission shafts play a crucial role in enabling vehicles to accelerate, decelerate, and maintain consistent speeds by efficiently transferring rotational energy.

The table below provides insights into the significance of transmission shafts in the automotive industry, highlighting their crucial role in power transmission and as essential components in the powertrain system. Discover how these shafts enable vehicles to efficiently transfer torque and convert engine power into forward motion, contributing to overall performance and drivability.

| Significance of Transmission Shafts in the Automotive Industry |

Description |

| Power Transmission |

Transmission shafts are crucial components in vehicles as they play a vital role in power transmission. They transfer rotational energy from the engine to the wheels, enabling the vehicle to accelerate, decelerate, and maintain consistent speeds. By efficiently transmitting torque, the transmission shafts ensure that the engine’s power is effectively converted into forward motion, allowing the vehicle to move efficiently and smoothly. |

| Essential Component in Powertrain System |

Transmission shafts are integral parts of the powertrain system in vehicles. They form a crucial link between the engine and the wheels, facilitating the transfer of power and torque. As key components in the drivetrain, the transmission shafts ensure that the engine’s power is efficiently delivered to the wheels, enabling the vehicle to move and perform various driving functions. The proper functioning of transmission shafts is essential for the overall performance, drivability, and efficiency of the vehicle. |

Aerospace Industry

In aircraft, transmission shafts play a critical role in controlling and regulating various systems and components. They facilitate seamless torque and rotational energy transmission for power distribution and flight control mechanisms. I’m sure you’re with me on this one… They enable the operation of essential aircraft systems, including engine accessories, flight control surfaces, landing gear, and auxiliary systems.

Marine Industry

Transmission shafts are essential components in boats and ships, transferring power from the engine to the propellers. They convert the engine’s rotational energy into propulsive force, driving the vessel through the water. For example, in a large cargo ship, transmission shafts enable the engines to transfer rotational energy to the propellers, allowing the vessel to navigate through water with enhanced power and control.

Industrial Machinery

In manufacturing plants, PVD coating transmission shafts play a crucial role in driving an extensive array of machines and tools. These shafts form the backbone of power transmission systems, enabling the efficient transfer of rotational energy from the source, such as an electric motor or engine, to various equipment and machinery. Suprotos is a trusted name that provides high-quality transmission shafts that meet varied requirements.

7. Factors Affecting Transmission Shaft Performance

The performance of a transmission shaft is influenced by various factors that significantly impact its operation and effectiveness. These factors encompass:

Torque

The torque transmission directly impacts shaft performance, determined by design, material, and structural integrity. A higher torque rating allows the shaft to handle greater power and rotational forces for reliable and efficient power transfer within the system. According to ScienceDirect, in the United States, torque tubes are utilized in gate drive applications, specifically for radial and vertical gates, to transmit torque to a hoist winch.

Speed

In high-speed operations, specialized shafts are essential to withstand increased demands, including elevated speeds, forces, and vibrations. These shafts are engineered to endure the unique stresses of high-speed applications. Amazing, isn’t it? By utilizing specialized high-speed shafts, businesses can confidently operate their machinery at elevated speeds, ensuring smooth and efficient performance under demanding conditions.

Vibrations

Minimizing vibrations optimizes machine operation and prolongs transmission shaft lifespan. Excessive vibrations accelerate wear and tear, impacting performance and reliability. How awesome is that? Maintaining a proper balance of the transmission shaft can have a remarkable impact on reducing operational vibrations and enhancing overall machine performance.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

In conclusion, transmission shafts are pivotal components in various machinery and vehicles. Understanding their features, types, materials, and factors affecting their performance can lead to better maintenance, longevity, and efficiency.

You won’t believe what we discovered… By staying knowledgeable about transmission shafts and their intricacies, businesses can make informed decisions, implement effective maintenance practices, and maximize the performance and lifespan of their machinery.

Looking to optimize your machinery or vehicles with the best transmission shafts? Reach out to us. Our team of experts will guide your business in making the best choice that suits your specific needs.