Correctness

A critical feature of CNC plastic machining services is the remarkable precision they offer. Due to the use of digital design files that guide the machine’s tool path, the final part is shaped with utmost accuracy. This high level of precision is maintained regardless of the volume of the production run.

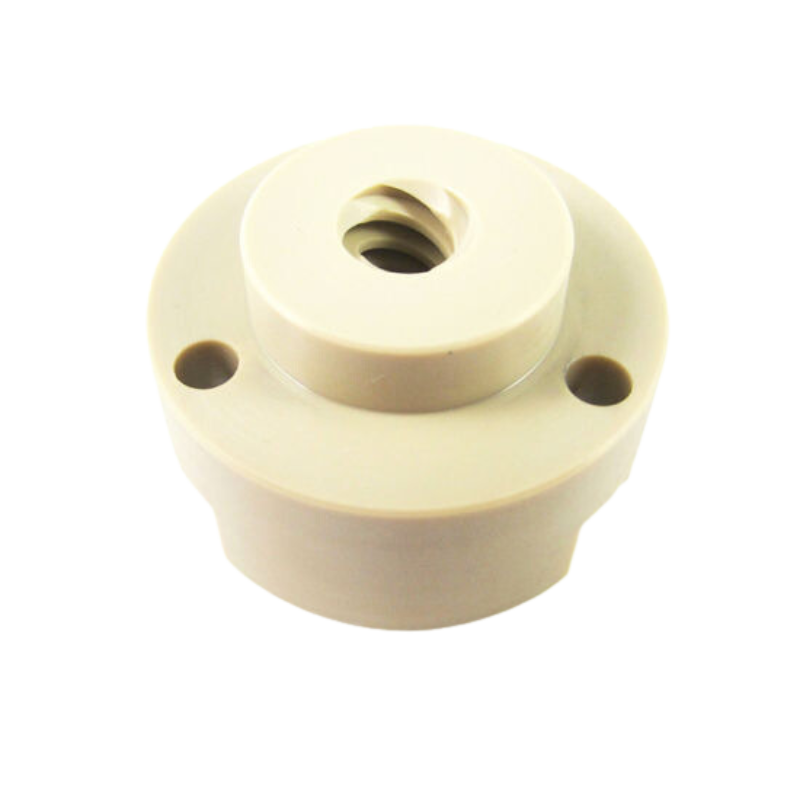

Flexibility in Design

CNC plastic machining services can handle complex geometries and create parts with very small or large dimensions. This flexibility extends the scope of design, thus opening doors to innovative product development.

Consistency

Consistency across multiple parts is a hallmark of CNC plastic machining services. They can repeatedly produce the same part with incredible accuracy, making this service an ideal choice for high volume production.

Wide Range of Compatible Plastics

CNC plastic machining is compatible with a wider range of plastics compared to other manufacturing methods. This adaptability empowers product teams with more choices for material selection. As an industry expert, I see the way that compatibility truly broadens the horizon for innovation and design possibilities.

Surface Quality

Another notable feature is the high degree of surface quality maintained in the parts produced. This factor is essential in manufacturing industries that require aesthetic appeal along with functionality.