What is Selective Laser Sintering (SLS), and why is it becoming a cornerstone in the landscape of modern manufacturing? The answers to this question might hold the key to the next evolutionary leap in your business.

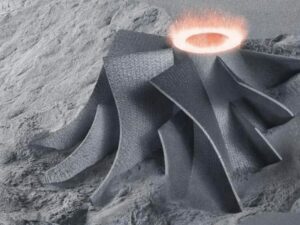

SLS is a powerful additive manufacturing technology that utilizes a laser to sinter powdered material layer by layer, according to a digital blueprint, to construct three-dimensional objects. This innovative technology is revolutionizing various industries by providing the ability to create complex geometries, use a wide range of materials, and adapt rapidly to design changes.

Read on to delve into the fascinating world of SLS printing.

1. Defining SLS Printing: A Brief Overview

When stepping into the realm of additive manufacturing, one encounters various groundbreaking technologies that are redefining the manufacturing process. According to LinkedIn, selective laser sintering, also known as SLS, is a 3D print technology that uses polymer powder to create parts. Technology fuses powder and creates strong, complex parts

2. History of SLS Printing

Peering into the history of SLS printing offers insight into its development and how it has progressively become an essential tool for numerous industries. Here, let us take a look at the journey of SLS printing:

Inception of SLS: The Early Years

The story of SLS printing began in the 1980s when Dr. Carl Deckard, a student at the University of Texas, proposed and developed the concept as part of his master’s thesis. Deckard’s idea was later commercialized by DTM Corp, which was eventually bought out by 3D Systems, one of the leading companies in the 3D printing market today.

SLS Printing: The Growth Phase

During the 1990s and 2000s, SLS printing experienced considerable growth and expansion. The process was continuously refined, and the range of materials that could be used with SLS expanded significantly. Thankfully, companies began to realize the value of SLS for prototyping and even production of end-use parts.

Modern SLS Printing: Integration and Advancement

In the recent decade, SLS printing has become an integral part of many industries. Technological advancements have further refined the process, making it more efficient and versatile. SLS has been adopted for various applications in industries such as automotive, aerospace, medical, and more. With continuous research and development, the future of SLS printing promises even more potential.

3. Advantages of SLS Printing

Embracing SLS printing can offer business owners numerous advantages, pushing the boundaries of traditional manufacturing methods. Here are some of the countless advantages of embracing SLS printing:

Design Freedom and Complex Geometries

SLS technology offers unprecedented design freedom. It can construct complex geometries that would be challenging, if not impossible, with traditional manufacturing methods. For instance, internal features, undercuts, thin walls, intricate details, and even interlocked or moving parts can be created with ease. This freedom allows for limitless creativity and innovation in product design.

Wide Range of Compatible Materials

The versatility of SLS printing is partly due to the wide range of materials it can handle. From different types of polymers like nylon and thermoplastic elastomers to metals such as aluminum and stainless steel, and even ceramics and composites, SLS technology is compatible with a broad array of materials. Believe me, this compatibility ensures that businesses can select the ideal material for their specific application.

Functional Prototyping and Production Capabilities

SLS printing is not just for prototypes; it’s equally effective for creating functional parts and end-products. Given the durability and high detail resolution of SLS printed parts, the technology is widely used for both functional prototyping and direct digital manufacturing of end-use parts. This dual capability enables businesses to streamline their product development and production processes.

4. Key Components of SLS Printing

Understanding the integral components of SLS machines can provide valuable insights into how the process works. Here, we will explore the key components of SLS machines, shedding light on their functionality and the importance of their maintenance:

Powder Bed

The powder bed is more than just a static component; it’s the stage where the magic of SLS printing unfolds. It consists of a precise layer of powdered material, usually ranging from 0.1mm to 0.15mm in thickness. As the laser sinters each layer according to the 3D design, the platform lowers, and the recoater spreads a new layer of powder.

Laser System

The laser system is undeniably the cornerstone of Suproto’s SLS printing. A high-power CO2 laser is utilized, which emits a beam of infrared light with significant energy. This laser doesn’t merely operate in a haphazard manner; it follows a specific path dictated by the digital file of the 3D design. It selectively targets areas in the powder bed, causing the powdered material to fuse at a granular level.

Scanning System

One might wonder how the laser beam accurately follows the 3D design path on the powder bed. The answer lies within the scanning system, an integral part of SLS printing. Controlled by the printer’s software, these mirrors move rapidly along the X and Y axes, directing the laser beam across the powder bed to accurately sinter the material according to the digital design.

Heating and Cooling Systems

The heating and cooling systems in an SLS printer play critical roles in ensuring a successful print. According to Matter Hackers, most print beds are heated in order to prevent the object from warping while it is being printed. During the process, the heating system maintains this temperature, while the cooling system kicks in after the printing is done, allowing the newly formed 3D object to cool and solidify.

5. Materials Used in SLS Printing

One of the major strengths of SLS printing lies in its compatibility with a diverse array of materials. Here are some of the diverse materials that showcase the major strengths of SLS printing:

Polymers (e.g., Nylon, Polyamide, Thermoplastic Elastomers)

Polymers are the most commonly used materials in SLS printing. The broad family of polymers includes materials like nylon and polyamide, each with its unique characteristics. Nylon, for instance, is known for its excellent strength-to-weight ratio, high durability, and flexibility, making it suitable for a wide range of applications, from mechanical parts to consumer goods.

Metals (e.g., Aluminum, Stainless Steel)

While SLS printing initially focused on polymers, the technology has expanded to accommodate metals. The ability to work with metals like aluminum and stainless steel opens new horizons for SLS printing. Aluminum, being lightweight and having excellent thermal properties, is widely used for parts that need to withstand high temperatures.

Ceramics and Composites

The use of ceramics and composite materials in SLS printing represents the continuous evolution of the technology. Ceramics can be used to create intricate designs for applications in the medical, aerospace, and electronic industries. In my opinion, composites can provide tailored characteristics, creating opportunities for highly specific applications.

6. Applications of SLS Printing

With its unique advantages and broad range of compatible materials, SLS printing has found its way into numerous industries, pushing the boundaries of what’s possible in each. Here are the remarkable ways in which SLS printing has made a profound impact across numerous industries:

Automotive and Aerospace

Within the automotive and aerospace sectors, SLS printing has proven to be an influential technology. Its ability to create lightweight and intricate components provides a clear advantage. Parts such as air ducts, motor housings, or even structural parts are now being produced with SLS, reducing the weight of vehicles and aircraft while maintaining structural integrity.

Medical and Healthcare

In the realm of medical and healthcare, SLS printing is making considerable contributions. At Suproto, customized patient-specific implants, surgical aids, and prosthetics can be manufactured efficiently with this technology. It allows for the creation of highly complex structures with interconnected channels or porous surfaces, which can promote better integration with the human body.

Consumer Products and Fashion

The world of consumer products and fashion is another realm where SLS printing is leaving its mark. From intricate jewelry designs to bespoke furniture, and from high-end fashion accessories to unique home decor items, the possibilities seem endless. Anyone will agree that the design freedom provided by SLS enables artists and designers to bring their most complex and intricate designs to life.

Architecture and Construction

In architecture and construction, SLS printing is used to create precise scale models of architectural designs, assisting architects in visualizing their projects and communicating their ideas more effectively. It also allows for rapid prototyping of construction components, enabling builders to test and refine their designs before production.

7. Limitations and Challenges of SLS Printing

While SLS printing holds incredible potential, like all technologies, it also comes with its share of challenges. Here are some of the limitations surrounding SLS printing:

Cost and Time Considerations

The initial investment for an SLS printing service machine can be quite substantial, presenting a potential barrier for small and medium-sized businesses. The problem is, while technology can accelerate the prototyping process, the printing speed for large volumes or large parts can be slower compared to traditional manufacturing methods, affecting the overall production timeline.

Surface Finish and Post-Processing Requirements

Parts produced by SLS often exhibit a slightly rough surface finish due to the sintered powder particles. While this texture might be acceptable or even desirable for some applications, others may require a smooth finish, necessitating post-processing steps such as sanding or polishing. Speaking from experience, this additional step could introduce further cost and time considerations.

Size and Build Volume Constraints

Although SLS printers can produce a wide range of part sizes, the maximum build volume is limited by the size of the powder bed. This means that larger parts may need to be printed in sections and assembled later, which could affect the part’s strength and integrity.

The table below provides an overview of different 3D printing technologies and their respective size and build volume constraints, including considerations for printing larger parts in sections and the potential impact on strength and integrity.

| Printer Technology |

Size and Build Volume Constraints |

Considerations |

| SLS (Selective Laser Sintering) |

Maximum build volume limited by powder bed size |

Large parts may need to be printed in sections and assembled later, potentially affecting strength and integrity |

| FDM (Fused Deposition Modeling) |

Build volume limited by the size of the printer’s gantry system |

Generally suitable for smaller to medium-sized parts; large parts may require printing in sections and assembly |

| SLA (Stereolithography) |

Build volume determined by the size of the resin vat |

Generally suitable for smaller to medium-sized parts; larger parts may require printing in sections and assembly |

| DLP (Digital Light Processing) |

Build volume determined by the size of the resin vat |

Similar considerations as SLA printers, suitable for smaller to medium-sized parts |

| Binder Jetting |

Build volume determined by the size of the build chamber and the size of the powder bed |

Large parts may require printing in sections and assembly |

| Material Jetting |

Build volume determined by the size of the print bed and the printing technology |

Generally suitable for smaller to medium-sized parts; larger parts may require printing in sections and assembly |

| DMLS/SLM (Direct Metal Laser Sintering/Selective Laser Melting) |

Build volume determined by the size of the powder bed |

Typically used for smaller to medium-sized metal parts; larger parts may require printing in sections and assembly |

| EBM (Electron Beam Melting) |

Build volume determined by the size of the powder bed |

Similar considerations as DMLS/SLM printers, suitable for smaller to medium-sized metal parts |

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available to assist and guide you.

Conclusion

SLS printing, with its multitude of applications and advantages, has the potential to transform traditional manufacturing methods and spur innovation. However, as with all technologies, it is not without its challenges. A thorough understanding of both its capabilities and limitations can enable businesses to leverage SLS printing effectively and optimize their production processes.

If you are contemplating the incorporation of SLS printing into your business and wish to acquire further information regarding its potential advantages and applications, contact us today! We will be delighted to offer expert guidance and customized solutions tailored to meet your specific business requirements.