Have you ever pondered how to turn digital blueprints into real-life objects? The process behind these marvels is 3D Printing technology, a transformative innovation that’s redefining how we manufacture goods. But what is 3D Printing technology?

Simply put, it’s a method of producing physical objects layer by layer from a digital model, most often using computer-aided design (CAD). This article promises to guide you on a comprehensive journey through the complex and fascinating world of 3D printing technology. I will help you unravel the magic behind 3D printing and the transformative impact it has on our future.

Read on to unveil the world of 3D Printing.

1. An Overview of 3D Printing

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital model by depositing material layer by layer until the final object is formed. The process begins with a digital design, usually a Computer-Aided Design (CAD) file, which is sliced into thin cross-sections for the printer to produce.

This technology has been hailed for its ability to facilitate rapid prototyping, customize products, and reduce material waste. According to SmarTech, the market for 3D printing in construction topped $40 billion in revenues by the end of the 10-year forecast period, illustrating the vast potential of this technology.

Over the past decade, 3D printing has grown from niche technology into a significant player in the manufacturing sector. From my own experience in the field, I can affirm that 3D printing is a game-changing tool that enables unprecedented creativity and innovation.

2. The Evolution of 3D Printing

The story of 3D printing isn’t a recent one. In fact, it’s a journey that spans over three decades, tracing technology from its inception to its current widespread application. Here, we explore the key milestones in the evolution of 3D printing.

The Birth of 3D Printing

The birth of 3D printing can be traced back to the 1980s, with Chuck Hull, who patented the process of stereolithography (SLA) in 1986. SLA uses UV lasers to solidify photopolymer, a type of liquid plastic, layer by layer, to create 3D objects. Hull’s invention paved the way for the development of other 3D printing technologies, such as Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM).

The Expansion and Diversification

The 1990s and 2000s witnessed significant advancements in 3D printing technology. During this period, the range of materials compatible with 3D printers expanded considerably, including ceramics, metals, and different types of plastics.

The rapid pace at which 3D printing is evolving never ceases to amaze me. Wherein, 3D printers became more affordable and accessible, marking the start of technology’s transition from industrial to home use.

The Rise of Industrial and Commercial Applications

From 2010s to present, the scope of 3D printing has exploded, reaching various industries like healthcare, automotive, aerospace, and consumer products. Over the years, I’ve had the privilege to witness this transformative journey firsthand. The development of new printing technologies, such as metal 3D printing and bioprinting, has further expanded the potential applications of 3D printing.

3. Advantages of 3D Printing

As 3D printing technology continues to mature, its advantages over traditional manufacturing methods become increasingly evident. Let’s delve into some of the most significant benefits it provides.

Reduction in Costs

3D printing can drastically reduce manufacturing costs in several ways. It eliminates the need for expensive molds and tooling used in traditional manufacturing methods. Here is something we can both agree with that the technology also minimizes material waste due to its additive nature, and reduces costs associated with storing inventory since items can be printed on-demand.

Increased Speed

One of the most prominent advantages of 3D printing is its ability to speed up product development. From initial design to the production of a tangible model, 3D printing can complete this process within hours, drastically reducing the time to market for new products. From my point of view, this acceleration can mean the difference between being first to market or playing catch-up with competitors.

Manufacture Complex Geometries

A study by PWC indicates that 51% of manufacturers expect 3D printing to be used for prototyping and final-products in the next 3-5 years. 3D printing excels at producing complex geometries that are often impossible or very difficult to achieve with traditional manufacturing methods. From intricate lattice structures to complicated organic forms, 3D printing can bring even the most complex designs to life.

4. Different Types of 3D Printing Technology

As the field of 3D printing has grown, so too have the types of technologies that power this innovation. Here, we will delve into three primary types of 3D printing technologies that are fueling transformations across various sectors.

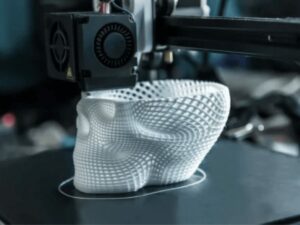

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most widely used 3D printing technology today. It works by extruding thermoplastic material layer-by-layer to create an object. FDM is well-suited for producing prototypes and functional parts due to its affordability, ease of use, and wide range of material options.

From my experience, understanding the unique capabilities of this 3D printing technology is crucial in determining the most suitable approach for any given project.

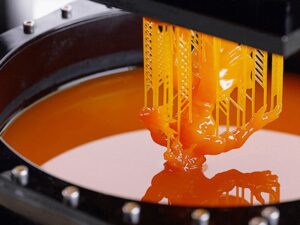

Stereolithography (SLA)

Stereolithography (SLA) was the first 3D printing technology to be invented. For example, when working on a project that required intricate architectural models, SLA was our go-to choice due to its exceptional level of detail and smooth surface finish.

It uses a UV laser to solidify photopolymer resins layer-by-layer. SLA is renowned for its high precision and surface finish, making it ideal for creating detailed prototypes, models, and production parts.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a high-power laser to fuse small particles of plastic, metal, or ceramic powders into a mass representing the desired 3D object. Here’s the interesting part that SLS can produce highly complex and robust parts without the need for support structures, and is often employed in applications that require high durability.

5. Materials Used in 3D Printing

The versatility of 3D printing extends to the plethora of materials that can be used. Whether it’s plastics, metals, or ceramics, each offers unique properties that can be exploited for specific applications.

Plastics

Plastics such as ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are commonly used in FDM 3D printing. ABS is robust and heat-resistant, making it perfect for creating durable parts. PLA, on the other hand, is biodegradable and safer to use, making it a popular choice for educational and home environments.

Metals

Metals, including stainless steel and titanium, are typically used in SLS or Direct Metal Laser Sintering (DMLS) technologies. Stainless steel is prized for its strength and corrosion resistance, while titanium combines lightness with incredible strength, making it ideal for aerospace applications. As I witnessed the resilience of these materials in 3D printing, I can vouch for their suitability in demanding applications.

Ceramics

Ceramics, though less commonly used than plastics or metals in 3D printing, offer excellent heat and corrosion resistance. In my line of work, the choice of material is often as important as the design itself. They are typically used in more specialized applications, including biomedical implants and high-temperature components.

6. Applications of 3D Printing

3D printing is much more than novel technology; it’s a revolutionary tool with the power to disrupt traditional manufacturing methods and reshape numerous industries. By enabling unprecedented design freedom, reducing lead times, and driving cost efficiency, 3D printing has found applicability in a diverse range of sectors. Here are the three pivotal fields where 3D printing is making significant inroads:

Manufacturing

3D printing, often referred to as additive manufacturing, has transformed traditional production methods. By building parts layer by layer, it reduces waste and allows for the production of complex geometries that would be impossible with traditional methods. Furthermore, 3D printing enables on-demand production, reducing inventory costs and speeding up the supply chain.

Medicine

In the field of medicine, 3D printing is advancing patient care and research. According to Precedence Research, the global 3D printing in the healthcare market is expected to reach USD 6.21 billion by 2023 at a CAR of 17.54%, indicating the significant impact this technology has on the sector.

It’s used to create patient-specific prosthetics and implants, model complex anatomical structures for surgical planning, and produce personalized medical devices. The future also holds the promise of bio-printing, where doctors could potentially print human organs for transplantation.

Architecture

3D printing is revolutionizing the architecture industry by offering new possibilities for building and model creation. Architects use 3D printing to create detailed architectural models for client presentations and construction planning. To illustrate, I’ve had the privilege of working on a project where 3D printing was employed to create a scaled model of a proposed commercial complex.

7. Challenges and Limitations of 3D Printing

As much as 3D printing is groundbreaking technology with countless benefits, it’s not without its fair share of challenges and limitations. Like any technology, it’s imperative to understand its shortcomings, not only to manage expectations but also to continually innovate and drive improvements. We will delve into four major areas where 3D printing faces hurdles:

Technical Limitations of 3D Printing

Despite its versatility, 3D printing technology still grapples with certain technical constraints. 3D printing processes can be relatively slow for mass production, making it less suitable for high-volume manufacturing. Here are some examples of technical limitations in 3D printing:

-

Limited material compatibility: Although the list of printable materials has grown over the years, it’s not unlimited. Not every material is compatible with 3D printing processes, which may restrict the kinds of objects that can be produced. Suproto, constantly researching and experimenting with various materials to expand the possibilities of 3D printing.

-

Size constraints: Larger objects often require industrial-sized printers which can be prohibitively expensive and require more space than is available in typical settings. Personally, I’ve encountered scenarios where 3D printing was not the best fit due to these size constraints.

-

Resolution and accuracy: While 3D printing can achieve remarkable detail, it is not always precise, especially when compared to traditional manufacturing methods. The resolution and accuracy can be influenced by several factors, including the quality of the printer, the printing technology used, and the properties of the printing material.

Cost Implications

While 3D printing can be cost-effective for small-scale, custom production, the initial setup costs and price of materials can be significant. This is especially true for industrial-grade printers and high-quality materials. Therefore, it may not always be the most economical choice, particularly for large-scale, uniform production.

I’ve noticed that a comprehensive cost-benefit analysis is crucial before implementing 3D printing in any operation. It’s not just about the cost of the printer, but also about material costs, operational costs, and the potential savings in design, production, and logistics.

The following table provides an overview of the cost implications associated with implementing 3D printing, emphasizing the importance of conducting a comprehensive cost-benefit analysis before incorporating this technology into operations.

| Cost Factors |

Description |

| Initial Setup Costs |

The upfront expenses associated with acquiring 3D printers, software, and necessary equipment. These costs may vary based on the type and quality of printers purchased. |

| Material Costs |

The cost of the raw materials used for 3D printing, such as filaments, resins, powders, or metals. The prices can vary depending on the material type, quality, and supplier. |

| Printer Maintenance Costs |

Regular maintenance and repair costs to keep the printers in good working condition. This includes cleaning, calibrating, and replacing components when necessary. |

| Labor Costs |

The expenses related to personnel involved in the operation, including technicians, operators, and designers who create and optimize 3D models for printing. |

| Energy Consumption |

The amount of electricity consumed by 3D printers during operation. Larger, industrial-grade printers may require more power and contribute to higher energy costs. |

| Post-Processing Costs |

Additional costs associated with post-processing activities, such as removing support structures, sanding, polishing, or painting the printed objects, if required. |

| Design and Prototyping |

Potential savings achieved by reducing the time and costs associated with traditional design and prototyping methods. 3D printing allows for rapid iteration and testing. |

| Production and Logistics |

Potential savings in production and logistics costs due to on-demand manufacturing, reduced inventory, and the ability to create complex or custom parts as needed. |

| Economies of Scale |

The impact of scaling up production on cost efficiency. While large-scale production can lower costs, it may not always be the most economical option with 3D printing. |

Quality Control and Standardization Issues

3D printing also faces issues of quality control and standardization. Given that this technology is relatively new, industry-wide standards for production and quality assurance are still in development. This can lead to inconsistencies in print quality and performance across different machines and materials. Let’s delve into these issues:

-

Inconsistency in output: Even when the same settings are used, 3D printed objects can show variations. This can be due to subtle changes in environmental conditions, differences in material properties, or slight changes in machine performance over time.

-

Lack of industry standards: As of now, the 3D printing industry lacks globally accepted standards for materials, processes, and testing methods. This lack of standardization can create difficulties for businesses to ensure their 3D printed products meet consistent quality levels, especially when different machines and materials are used.

-

Post-processing variances: The quality of the final 3D printed product is often heavily influenced by post-processing steps, such as support removal, surface smoothing, and curing. The manual nature of many of these steps can introduce significant variability in the final product quality.

-

Material quality control: There can be significant variations in the quality of 3D printing materials between different suppliers, and even between different batches from the same supplier. These variations can significantly impact the strength, durability, and appearance of the final printed product.

-

Machine calibration issues: The precision of 3D printing machines can drift over time, requiring frequent calibration to ensure accurate output. This is particularly true for businesses using multiple 3D printers, where slight differences in calibration can result in significant differences in the final products.

Environmental Considerations

There are environmental considerations to keep in mind with 3D printing. While technology can reduce waste in manufacturing, the energy consumption of 3D printers is relatively high. Let’s familiarize these considerations:

-

Energy consumption: 3D printers, especially those operating on high energy-consuming technologies like Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS), use a substantial amount of energy. This could be an environmental concern, particularly when the energy is sourced from non-renewable resources.

-

Waste generation: While 3D printing can reduce waste compared to traditional manufacturing methods by only using the material needed for the product, there’s still waste generated, especially during failed prints or support structure disposal. Suproto, prioritize sustainable practices and are always seeking innovative solutions to minimize waste.

-

Material choices: Many 3D printers use plastics like ABS and PLA for printing. While PLA is a biodegradable material derived from renewable resources, ABS is a petroleum-based plastic. The environmental impact of sourcing these materials and the potential pollution caused by their disposal are significant considerations.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available to assist and guide you.

Conclusion

3D printing is a transformative technology that’s redefining the manufacturing landscape. Having been immersed in the world of 3D printing for years, I’m continually amazed by its endless possibilities and future potential. I encourage anyone curious about incorporating 3D printing into their operations to reach out.

Don’t hesitate to contact us for more information or if you have any questions about 3D printing technology. We’re here to assist you on this exciting journey into the future of manufacturing. Remember, the only limitation in 3D printing is your imagination!