Have thoughts ever crossed your mind about what allows certain industrial components to maintain exceptional durability and low friction resistance? The enigma unwraps around a thin, high-performance surface treatment method known as Diamond-Like Carbon (DLC) Coating.

This comprehensive guide will illuminate the unparalleled properties of DLC coating, its numerous benefits, the diverse application techniques it entails, and the wide range of industries it caters to.

Read on and discover the fascinating world of DLC coating and its transformative impact on various industrial applications.

1. A Brief Overview of DLC Coating

Diamond-Like Carbon (DLC) Coating symbolizes a special category of material exhibiting properties akin to natural diamonds.

The treatment involves coating various substrates to elevate their functional performance and extend their service life. According to Science Direct, DLC coatings can be amorphous, more or less flexible, hard, strong, and slick according to the composition and processing method.

2. Benefits of DLC Coating

DLC Coating emerges as a game-changer across multiple industries, offering a spectrum of benefits. Here are some of the advantages that DLC coating brings along.

Improved Hardness and Wear Resistance

One of the most profound benefits of DLC coating is the extraordinary hardness it imparts to the substrate.

The diamond-like structure provides excellent wear resistance, significantly prolonging the life of coated components.

This enhancement allows substrates to withstand rigorous, high-stress operations without succumbing to wear and tear, ensuring consistent performance and reducing downtime.

Enhanced Friction and Lubricity

DLC coating acts as a powerful agent to mitigate friction, bestowing

substrates with enhanced lubricity.

This reduction in friction drastically improves the overall efficiency of the components, facilitating smooth operation and minimizing energy losses.

Furthermore, it aids in lowering heat production and subsequent thermal stress, particularly vital in high-speed operations.

Corrosion Protection

In addition, to wear resistance, DLC coating excels in offering excellent protection against corrosion.

Based on my research, it shields the substrates from a variety of environmental elements, such as moisture, oxygen, and corrosive chemicals, thereby averting any potential damage or degradation.

Thermal Stability

At Suproto, the thermal stability of DLC coatings is remarkable. They maintain their mechanical and physical properties even in high-temperature environments, ensuring reliable and consistent performance.

This quality makes them a preferred choice for applications with challenging thermal conditions.

Biocompatibility

Interestingly, DLC coatings exhibit biocompatibility, making them safe for use in medical devices and implants. Their non-toxic nature, coupled with their durability and resistance to corrosion, makes them ideal for applications where prolonged contact with body fluids or tissues is expected.

3. DLC Coating Techniques

DLC coating employs various techniques to meet the specific requirements of diverse applications. Below are the main methods of application of DLC coating.

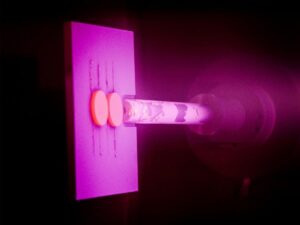

Chemical Vapor Deposition (CVD)

At Suproto, CVD is a frequently utilized method for applying DLC coatings. It involves the deposition of gaseous reactants onto the substrate, leading to the formation of a solid coating.

Trust me, this method excels in coating complex-shaped components and ensuring uniform coverage.

Physical Vapor Deposition (PVD)

PVD forms another common technique for DLC coating application. Amazing, right? It employs physical methods to vaporize the coating material and deposit it onto the substrate.

PVD can provide superior adhesion and a wide range of coating properties, making it suitable for a variety of applications.

Hybrid DLC Coatings

Hybrid DLC coatings represent a combination of different techniques to optimize the performance and longevity of the coated components.

They are designed to leverage the strengths of multiple methods and mitigate their weaknesses, resulting in coatings that deliver the best of all worlds.

4. Applications of DLC Coating

DLC Coating finds utility in a plethora of industries, each leveraging its unique properties to enhance the performance and durability of components. Let’s delve into the key application below.

Automotive Industry

DLC coatings are extensively employed to elevate the durability and efficiency of engine parts. For example, DLC coatings are used on components such as camshafts, pistons, and bearings to reduce friction, increase hardness, and improve fuel efficiency.

According to

InTech Open, DLC can be applied to automobile engine components in an attempt to provide energy efficiency by reducing friction and wear.

Aerospace Industry

In the demanding environment of aerospace, DLC coatings come into play to provide excellent wear resistance and thermal stability.

They are used in various parts, from engine components to landing gear, ensuring reliable operation even under extreme conditions.

Thanks to their superior properties, DLC coatings help to reduce maintenance costs and increase the reliability of aerospace components.

Medical Devices

Owing to their

biocompatibility, DLC coatings are increasingly being employed in the medical industry. They are used on various medical devices and implants, including heart valves, orthopedic implants, and surgical instruments.

The coatings ensure durability and longevity, reduce friction for better functionality, and provide resistance against body fluids and tissues.

Cutting Tools

DLC coatings play a pivotal role in enhancing the performance and lifespan of cutting tools. They help to increase tool hardness, decrease friction, and prevent material adhesion, leading to cleaner cuts and longer tool life.

These benefits are critical in industries such as machining, metalworking, and woodworking.

Firearms and Defense

In the realm of firearms and defense, DLC coatings find wide application due to their excellent wear resistance, low friction, and corrosion resistance.

They are applied to various parts, from barrels to firing pins, improving their durability and performance. This ensures reliable operation, which everyone will agree, is paramount in defense applications.

5. DLC Coating vs. Other Surface Treatments

DLC Coating stands in comparison with other surface treatments. Below, let us explore how it fares against other methods.

DLC vs. PVD Coating

While both DLC and PVD coatings offer increased hardness and wear resistance, DLC coatings usually offer superior friction reduction and can be applied in thinner layers, making them ideal for applications where size and weight are critical considerations.

However, the choice between the two often depends on the specific application and its requirements.

The table below provides a comprehensive comparison between DLC (Diamond-Like Carbon) and PVD (Physical Vapor Deposition) coatings, highlighting their key properties such as hardness, wear resistance, friction reduction, coating thickness, and considerations for size and weight, helping you make an informed decision based on your specific application requirements.

| Property |

DLC Coating |

PVD Coating |

| Hardness |

High |

High |

| Wear Resistance |

Excellent |

Excellent |

| Friction Reduction |

Superior |

Good |

| Coating Thickness |

Thin |

Variable (can be thicker) |

| Size and Weight |

Ideal for critical size and weight considerations |

May have more flexibility in size and weight constraints |

| Adhesion to Substrate |

Good |

Good |

| Temperature Resistance |

Moderate to High |

Moderate to High |

| Deposition Method |

Various techniques (e.g., plasma-assisted CVD) |

Physical vapor deposition |

| Surface Finish |

Smooth |

Smooth to textured |

| Cost |

Relatively higher |

Relatively lower |

DLC vs. Nitriding

Nitriding, a process of diffusing nitrogen into the surface of a metal, is another common surface treatment. However, it does not offer the same level of corrosion resistance or low friction as DLC coatings.

Plus, DLC coatings can be applied to a wider range of materials, including non-ferrous metals and alloys.

DLC vs. Ceramic Coating

Ceramic coatings, like DLC coatings, provide increased hardness and wear resistance. However, they tend to lack the low friction and biocompatibility offered by DLC coatings. Hence, for applications such as medical devices or high-speed components, DLC coatings may be more suitable.

6. Maintenance and Care for DLC Coatings

Proper maintenance of DLC coatings is instrumental in capitalizing on their optimal properties and ensuring prolonged service life.

Here are key considerations involved in the upkeep of DLC-coated components:

Cleaning and Inspection

To maintain the superior performance of DLC coated parts, it’s paramount to perform regular cleaning and inspection. Cleaning processes should be gentle yet effective, focusing on the removal of accumulated grime, foreign particles, or other residuals that could potentially affect the functioning of the coating.

Care must be taken not to employ abrasive cleaning tools or solutions, which may inadvertently harm the coating.

Lubrication Considerations

Despite the inherently low friction of DLC coatings, certain applications might benefit from supplementary lubrication.

This additional step can further minimize friction and wear, thereby extending the lifespan of the coated component. It is highly important to select lubricants that are compatible with the DLC coating and do not cause any adverse effects.

Avoiding Abrasive Materials and Harsh Chemicals

In maintaining and cleaning DLC coated parts, the use of abrasive materials or harsh chemicals should be strictly avoided. These substances can inflict damage on the coating, thereby diminishing its effectiveness.

I suggest always opting for mild cleaning agents and soft cleaning tools that will not scratch or degrade the coating.

Reconditioning and Recoating Options

Should a DLC coated part exhibit signs of excessive wear or damage, reconditioning, and recoating options are available. These processes can restore the component to its optimal state.

Reconditioning usually involves surface preparation and cleaning before applying a fresh coat of DLC. These options can significantly extend the component’s service life, making them a cost-effective alternative to part replacement.

7. Challenges and Limitations of DLC Coating

While the advantages of DLC coating are plentiful, it is not devoid of certain challenges and limitations. Here are some aspects for a comprehensive understanding of its applications and performance.

Coating Delamination

Delamination or separation of the DLC coating from the substrate presents one potential challenge. This issue can emerge due to insufficient adhesion, extreme mechanical stresses, or fluctuating temperatures. Although rare, when delamination occurs, it can drastically affect the performance of the coated part.

To mitigate this issue, strict adherence to the optimal coating process and substrate preparation is of utmost importance.

Substrate Compatibility Issues

Though DLC coatings boast of wide-ranging compatibility with diverse materials, certain substrates may not optimally interface with the coating. This incompatibility can result in subpar adhesion, hardness, and even accelerated wear of the coating.

The solution is a thorough evaluation of substrate material. It is crucial before applying the DLC coating to ensure optimal performance and longevity.

Cost Considerations

A point to consider regarding DLC coatings is the associated cost, which can be higher than other conventional coating processes.

This is predominantly due to the specialized equipment and advanced technologies involved in the DLC coating process. However, it’s imperative to consider the long-term benefits that these coatings provide, which can balance the initial investment.

Temperature Limitations

Even though DLC coatings are celebrated for their remarkable thermal stability, they are not impervious to extremely high temperatures. Above certain temperature thresholds, DLC coatings can start to degrade or lose some of their beneficial properties.

In my opinion, this limitation necessitates a careful assessment of the operational environment’s temperature range before choosing DLC coating.

8. 4 Factors Affecting DLC Coating Performance

Several variables can influence the overall performance of DLC coatings. Here are some factors that allow optimized applications and superior end results.

#1 Substrate Material Selection

One of the most critical determinants of DLC coating performance is the selection of the substrate material. Various materials can interact differently with the coating, thereby affecting its final properties, including adhesion strength, hardness, and wear resistance.

Speaking from experience, it’s crucial to select a substrate that is compatible with DLC coating to ensure a successful application.

#2 Coating Thickness

The thickness of the DLC coating, similar to the use of

drill rod, significantly impacts its overall performance and durability. While a thicker coating might provide superior protection and hardness, it can introduce increased mechanical stresses, potentially leading to coating delamination. Conversely, a coating that is too thin may not provide the necessary wear resistance or durability.

#3 Adhesion and Interfacial Properties

The adhesion between the DLC coating and the substrate significantly influences the coating’s performance and longevity. Subpar adhesion can lead to premature coating failure or delamination.

Additionally, the interfacial properties, including the chemical bonding and mechanical interlocking at the coating-substrate interface, can affect the coating’s resistance to wear and other detrimental conditions.

#4 Operating Environment

The environment in which the DLC coated component operates can substantially affect the coating’s performance. For instance, factors such as temperature, pressure, exposure to corrosive substances, and mechanical stress can influence the durability and effectiveness of the coating.

Thus, an accurate understanding of the operating conditions is crucial during the selection and application of a DLC coating.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

DLC coatings offer an impressive range of benefits, from enhanced hardness to superior wear resistance and biocompatibility, making them a top choice for many industries. Despite a few limitations and challenges, understanding the intricacies of the process and the factors influencing performance can help make the most out of this exceptional surface treatment.

For businesses aiming to harness the power of DLC coatings, it is agreeable that partnering with a seasoned expert in the field is vital. Suproto, a leading DLC coating manufacturer, brings a wealth of experience and a promise of quality.

Feel free to contact us for more information and to explore how we can assist in elevating component performance and longevity.