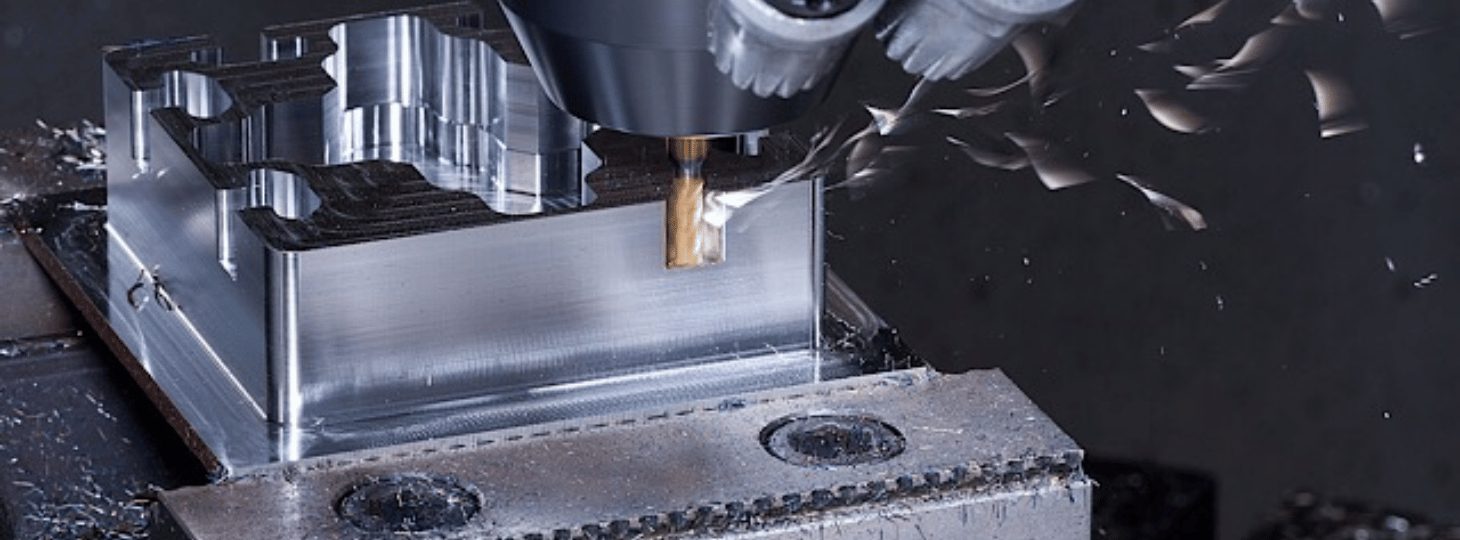

Industrial

CNC machining revolutionizes manufacturing with its precise detailing, consistency, and ability to work with various materials, boosting productivity and ensuring superior quality in heavy industries. From my experience, CNC machining has revolutionized heavy industries by delivering unparalleled precision, versatility, and productivity. This technology has a remarkable impact on manufacturing processes.

Automotive

With CNC’s precision, the automotive industry has seen unprecedented advancements. It allows for the manufacture of intricate car parts, from engines to suspension components, with impeccable accuracy and speed, reducing overall production time. Suprotos excels in providing such precision-focused solutions.

Aerospace

Due to the critical nature of aerospace components, CNC machining plays an integral role. It helps create high-strength, lightweight parts that meet stringent industry standards, improving fuel efficiency and overall safety. For instance, the machining of titanium, a common aerospace material, requires advanced CNC systems for optimal precision.

Medical

The medical industry requires highly accurate, complex components. CNC machining caters to this need, enabling the creation of everything from surgical instruments to orthopedic implants. This level of precision improves patient safety and treatment outcomes. The medical device market is projected to reach $432.6 billion by 2025, growing at a CAGR of 4.1% from 2020 to 2025 as stated by the PR Newswire.