Have you ever wondered what underpins the marvels of modern industry, ensuring they are manufactured with incredible accuracy and precision? As we admire our high-tech devices or drive our finely-tuned cars, seldom do we consider the intricate craftsmanship that has gone into making these products. The culprit behind this meticulous work is often an unsung hero: precision machining.

However, with precision machining, though, is its complexity and relative obscurity. Many people may not understand what it is or why it’s so critical. So, let’s cut to the chase: Precision machining is a manufacturing process that involves creating intricate parts with exceptional accuracy, using advanced machines capable of producing high-quality micro-products or features with meticulous detail.

So, let’s explore this essential manufacturing marvel together!

1. Overview of Precision Machining

The world of manufacturing is complex, evolving, and challenging. Yet, amidst challenges, a process has emerged that transforms raw materials into precise components with utmost finesse – Precision Machining.

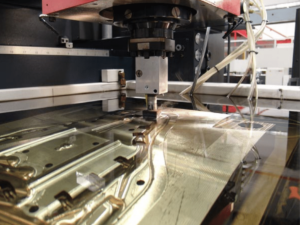

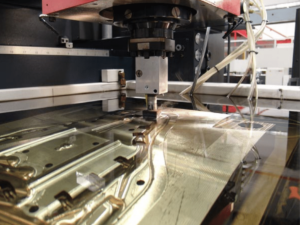

Precision machining is a type of machining process that uses computer-controlled machine tools for parts production. It not only shapes large pieces of material, but ensures they meet exact specifications. This includes procedures such as cutting, milling, turning, and electrical discharge machining, typically performed using Computer Numerical Control (CNC) equipment, according to Goodwin University.

Personally, as a CNC machine expert, the beauty of precision machining lies in its blend of artistry and science. This process produces large and small objects similar to what we use in daily life. It is truly remarkable how every single piece of an object can require a machinist’s skills.

2. A Brief History of Precision Machining

Delving into the past, we gain insights into the fascinating evolution of precision machining, a technique that has revolutionized manufacturing over centuries. From humble beginnings to the rise of modern, computer-controlled operations, precision machining’s history is marked by innovation and ingenuity.

History of Precision Machining:

- 18th Century: The development of steam engines in the 18th century led to the birth of precision machining. The manufacturing of precise, interchangeable parts for these engines marked the first significant use of precision machining techniques. It’s fascinating to think how this 18th-century invention laid the groundwork for the work I do every day.

- 1798: Eli Whitney secured a government contract to produce 10,000 muskets, pioneering the concept of standard parts with uniform dimensions, a fundamental principle in precision machining.

- 19th Century: The invention of the milling machine and the metal lathe in the 19th century were game-changers, introducing new levels of precision and control in machining operations.

- 1949: The first numerical control (NC) machine was created by John T. Parsons, drastically improving the accuracy and repeatability of machining operations.

- 1952: The Massachusetts Institute of Technology (MIT) developed the first computerized numerical control (CNC) machine, marking the beginning of the computer revolution in precision machining.

- 1970s-80s: During these decades, advancements in microprocessors and software technology further enhanced the capabilities and performance of CNC machining, making it the standard in precision manufacturing.

- 2000 to Present: Today, advancements in automation, artificial intelligence, and data analytics continue to propel the industry forward, offering unprecedented levels of precision, efficiency, and adaptability in machining processes. As someone deeply invested in this field, the speed of this technological revolution is both awe-inspiring and thrilling.

3. Types of Precision Machining

In the sphere of manufacturing, precision machining has carved a niche for itself, diversifying into numerous types that offer unique capabilities and advantages. Here, take a closer look at four major types of precision machining:

CNC Milling

A versatile process, CNC milling involves the use of computer controls to operate and manipulate machines and cutting tools to shape a workpiece. This process can create complex shapes and high precision parts from a variety of materials.

It’s also capable of multi-axis machining, providing superior accuracy and repeatability. Suproto leverage this technology to deliver unparalleled precision and efficiency in all our milling projects.

CNC Turning

This process utilizes a cutting tool that moves in a linear fashion while the workpiece rotates. CNC turning uses a machine to create perfect for creating cylindrical parts, offering high precision and speed.

A fitting example of the application of this method is in the aerospace industry, where intricate and highly accurate parts are a norm. The production of aircraft engine components often involves all this type of precision machining.

EDM Machining

A process in which electrical discharges are used to remove material from a workpiece. EDM can shape hard metals and produce complex shapes with high precision that are not possible with other machining methods.

As a CNC machine expert, I’ve witnessed the exponential growth and capabilities of these machining methods. Their ability to handle complex and high-precision tasks with remarkable efficiency is genuinely impressive.

Laser Machining

This employs a high-powered laser to cut, drill, or weld materials. Laser machining is particularly advantageous when dealing with materials that are difficult to machine using traditional methods, as it offers high precision and minimal physical impact on the workpiece. Laser machining is, to me, akin to a surgical procedure – precise, clean, and efficient.

4. Materials Used in Precision Machining

When it comes to precision machining, the choice of material plays a critical role in determining the overall success of the operation. Various materials such as metals, plastics, and ceramics have their unique properties, benefits, and challenges.

Let’s delve deeper into these materials and understand their characteristics, applications, and the considerations one must keep in mind during machining.

| Material |

Characteristics |

Applications |

Machining Considerations |

| Metals |

Metals, including steel, aluminum, brass, and others, are known for their high strength, durability, and heat resistance. They can be easily shaped and are good conductors of electricity. |

They are used extensively in automotive, aerospace, construction, and many other industries. |

Metals are generally machinable, but the specific techniques used may vary depending on the hardness and ductility of the metal. Care must be taken to manage heat during machining. |

| Plastics |

Plastics are typically lighter than metals, and they offer good resistance to chemicals and corrosion. They can also be flexible or rigid based on their composition. |

They are used in a variety of applications, from packaging and consumer goods to automotive parts and medical devices. |

Plastics are softer and more sensitive to heat compared to metals. Proper temperature control and sharp cutting tools are critical to prevent melting or deformation. |

| Ceramics |

Ceramics are extremely hard and resistant to heat and corrosion. They are also electrically insulative. |

They find applications in electronics, medical devices, aerospace, and more due to their unique properties. |

Due to their hardness, ceramics can be difficult to machine and often require specialized machining techniques like grinding or ultrasonic machining. Care should be taken to prevent cracking. |

Take note that the material characteristics, applications and considerations, varies on several factors, such as the usage and process. According to a report by Data Intelo, the global metal fabrication market is anticipated to expand at a CAGR of around 4% during the forecast period, 2020 – 2026.

From my experience in the field, I’ve always found it fascinating how we can shape these diverse materials into incredibly intricate and precise components. It’s a testament to how far precision machining technology has come.

5. Key Concepts in Precision Machining

Precision machining relies on several critical concepts that govern the quality and efficiency of the final product. Three of these key concepts are listed below:.

Tolerance

In precision machining, tolerance refers to the permissible limit of variation in the physical dimensions of a manufactured part. It’s a measure of the allowed deviation from the intended design, playing a significant role in determining the quality and functionality of a part. Having spent countless hours in the workshop, I can confidently attest that getting this aspect right can make or break the performance of a part.

Surface Finish

This concept relates to the texture, roughness, or smoothness of a part’s surface after machining. I have witnessed the art of balancing these factors that can achieve the desired result is one of the things I find most engaging in precision machining. A better surface finish often means higher quality, as it can influence the part’s performance, longevity, and ability to resist wear.

Machinability

According to a study in Science Direct, machinability can be defined as the ease with which the material is machined in terms of specific energy, specific horsepower, or shear stress. Factors influencing machinability include hardness, ductility, thermal conductivity, and chip breaking.

As an example, consider the manufacturing of automotive engine parts, where components must be made from materials with high machinability to ensure efficient manufacturing and optimum performance.

6. Precision Machining Processes

Precision machining processes are the heart of manufacturing, responsible for transforming raw materials into functional components with exceptional accuracy. They include various techniques, each offering unique capabilities that cater to specific needs. Understanding these methods helps in selecting the optimal process for a particular application, thus ensuring efficient and economical manufacturing.

Here are five steps that are often involved in precision machining processes:

Step#1 Planning and Design

This involves creating detailed blueprints of the final product using computer-aided design (CAD) software. These blueprints serve as instructions for the CNC machines, ensuring they know what cuts to make, where to make them, and how deep they should be. This step is crucial in ensuring that the final product meets the required specifications.

Step#2 Setting Up the Machine

Once the design process is complete, the next step is to set up the CNC machine. This includes loading the design files into the machine’s computer, setting up the appropriate cutting tools, and positioning the raw material. Proper setup is crucial for ensuring accuracy and precision in the final product.

Step#3 Milling

This is a machining process where a rotating cutting tool, the mill, removes material from the workpiece. The mill moves across the workpiece in several directions, allowing for the creation of a wide range of shapes and features. Precision milling is used for producing complex parts with tight tolerances and excellent finishes.

Step#4 Turning

Turning involves rotating the workpiece while a single-point cutting tool moves in a linear motion. This removes material from the workpiece, shaping it into the desired form. As a professional in the field, I can emphasize enough the importance of understanding these processes, wherein recision turning allows for the production of cylindrical or round parts with high dimensional accuracy and surface finish.

Step#5 Drilling

In drilling, a rotating cutting tool known as a drill bit is pressed into the workpiece to create holes. The process is widely used in precision machining to make accurate and consistent holes in various materials. Precision drilling is a fundamental step in many machining applications. Having drilled countless holes in my career, I can tell you that the precision this method offers is second to none.

Step#6 Grinding

Grinding uses an abrasive wheel as the cutting tool to remove material from the workpiece’s surface. It’s mainly used for achieving superior surface finish and extreme dimensional accuracy. Precision grinding is essential when the application requires parts with very tight tolerances and high levels of surface finish

7. Applications of Precision Machining

Precision machining forms the backbone of various industries, paving the way for innovative applications by allowing the creation of complex and precise components. Its remarkable level of precision, efficiency, and consistency makes it indispensable in many sectors. Here are the sectors that precision machining stands out:

Industrial and Manufacturing

- Machine Components: Precision machining is integral in creating components for machines in various industries. These parts require high accuracy and consistency, thus demanding the precision only this technique can provide.

- Assembly Line Parts: The mass production of goods in assembly lines relies on components produced by precision machining. These parts need to fit perfectly and function flawlessly to ensure smooth operations.

- Engine Parts: Precision machining allows for the production of intricate engine parts, which demand exact tolerances and measurements for efficient performance. From my perspective, as a professional in this field, the engine is like the heart of a machine and precision machining, its pulse.

Medical and Biotechnological

- Surgical Instruments: The medical field relies heavily on precision machining for the production of surgical instruments. The high level of precision ensures that these tools function reliably during critical procedures.

- Orthopedic Implants: Orthopedic implants such as artificial joints require extreme precision for proper fit and function. Precision machining provides the necessary accuracy for creating such intricate components.

- Biotechnological Equipment: Precision machining is critical for the biotech industry, producing the highly accurate components required in sophisticated laboratory equipment.

Aerospace and Automotive

- Engine Parts: Precision machining is vital in manufacturing various engine components for both the aerospace and automotive industries. These parts must meet strict tolerances to ensure optimal performance.

- Transmission Components: Precision machining is used to produce transmission components, which must be incredibly accurate to provide smooth and reliable vehicle operation.

- Airframe Parts: In the aerospace industry, precision machining is used to produce parts of the airframe, where high accuracy and durability are required due to the harsh conditions encountered during flight. As a long-time enthusiast of aerospace technology, I can’t help but marvel at how precision machining has revolutionized this industry.

8. Precision Machining vs. Traditional Machining

Precision Machining and Traditional Machining, two key manufacturing methodologies, have unique advantages and characteristics that suit different requirements and applications. Understanding the contrast between these two approaches is crucial for manufacturers, as it can profoundly impact the totality of production. Let’s analyze these differences through the table below:

| Criteria |

Precision Machining |

Traditional Machining |

| Accuracy |

Precision machining offers a high level of accuracy, typically within a few microns. |

Traditional machining has lower accuracy compared to precision machining. |

| Tolerance |

It can handle extremely tight tolerances. This is critical for industries like aerospace and medicine where even a small variance can lead to significant problems. |

It can deal with more generous tolerances, which is suitable for less critical parts. |

| Surface Finish |

It often results in better surface finishes, which can reduce the need for secondary processes like polishing. |

The surface finish from traditional machining might require additional processes to achieve the desired quality. |

| Complexity |

Precision machining can handle complex geometries and designs that might be impossible with traditional methods. |

Traditional machining is typically better suited for simpler parts and designs. |

| Time and Cost |

Although the initial setup cost can be high, precision machining can be faster and more cost-effective for complex parts or high-volume production. |

Traditional machining might have lower setup costs and can be cost-effective for simpler parts or low-volume production. |

| Material Waste |

Precision machining tends to produce less waste, as it removes only the necessary material. |

Traditional machining might generate more waste, depending on the part’s complexity and the operator’s skill. |

Keep in mind that the choice between precision and traditional machining will depend on the specific requirements of the project, including factors like part complexity, production volume, and tolerance demands. This is where a manufacturer like Suproto stands out with its commitment to evaluating these factors to provide the optimal machining solution.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

In the vast world of manufacturing, precision machining stands as a pillar of quality and efficiency, driving the production of components that make up our everyday devices and machinery. At Suproto, we share your passion for precision and detail.

Whether you are a seasoned professional in the field or a curious newcomer interested in learning more about precision machining, we welcome your questions and ideas. Contact us anytime for more information or product details. After all, it’s through shared knowledge that we build, create, and innovate. We’re just a click away!