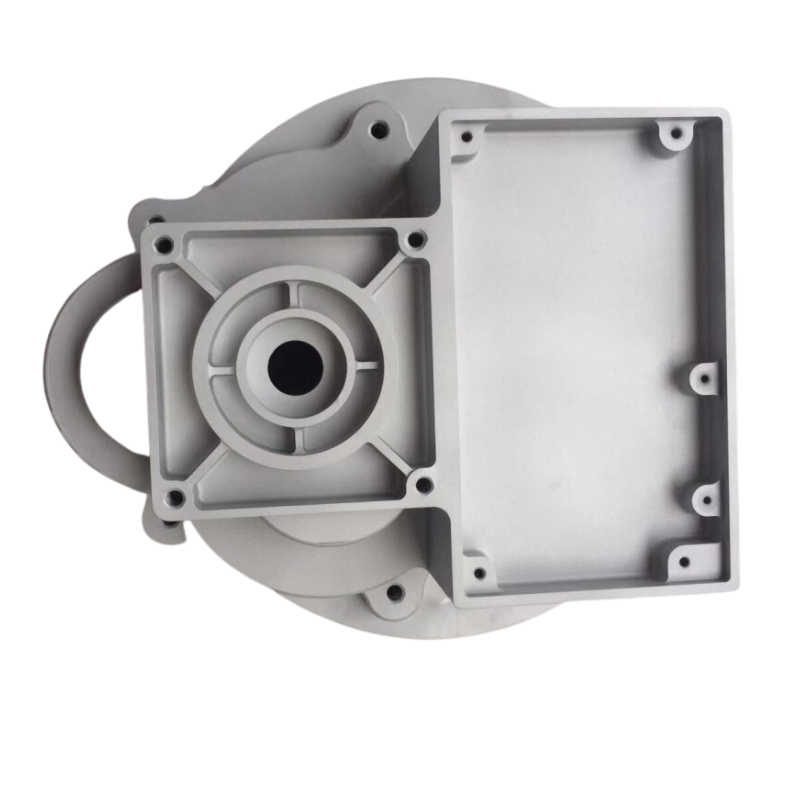

#1 Type of Metal Used

The first and foremost consideration is the type of metal used. Not all stainless steel is created equal and the specific alloy used can have a significant impact on the final product’s properties. Variations in the composition of stainless steel can affect several factors examples are hardness, corrosion resistance, and machinability.

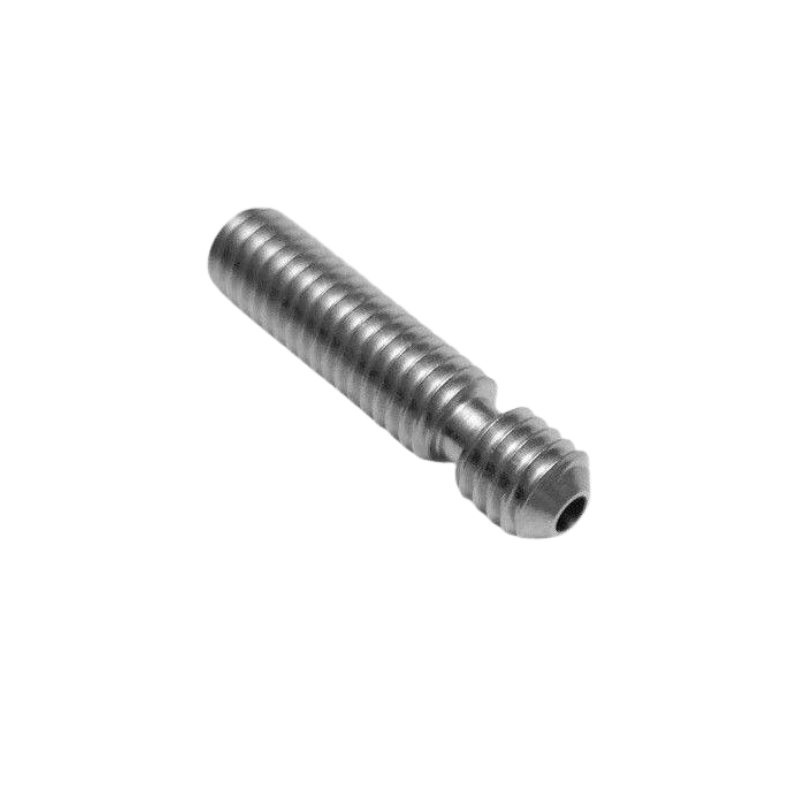

#2 Technology Used for Printing

Data Bridge Market Research analyses that the 3D printing metals market will witness a CAGR of 30.77% for the forecast period of 2021-2028. With this significant growth of 3D printing, technology used by the service plays a pivotal role. Some examples of techniques are Powder Bed Fusion, Directed Energy Deposition, and Binder Jetting are common in the industry.

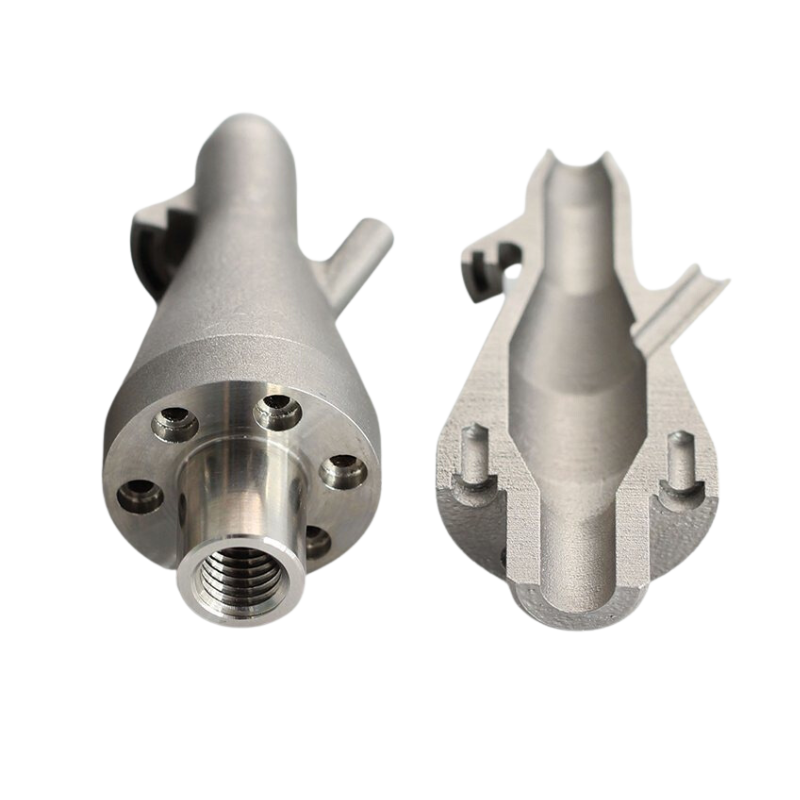

#3 Accuracy and Resolution

The precision of a 3D printing service determines how closely the final product will match the original design. High-resolution printing is especially important when creating intricate designs or components that need to fit together precisely. Having worked extensively with precision tasks, I can’t stress enough the importance of a meticulous and detail-oriented approach to ensure the highest degree of accuracy.

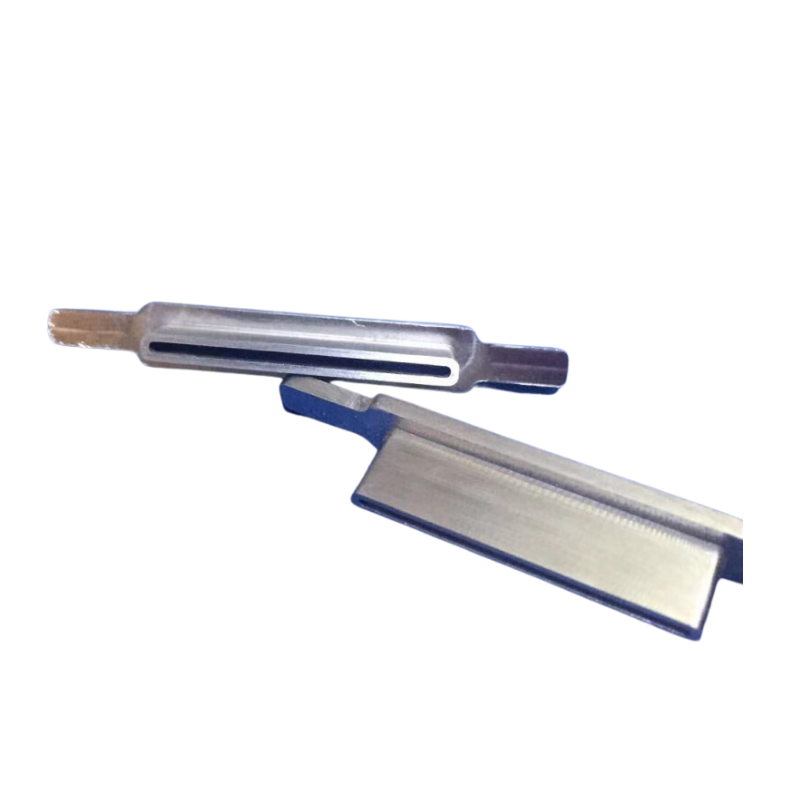

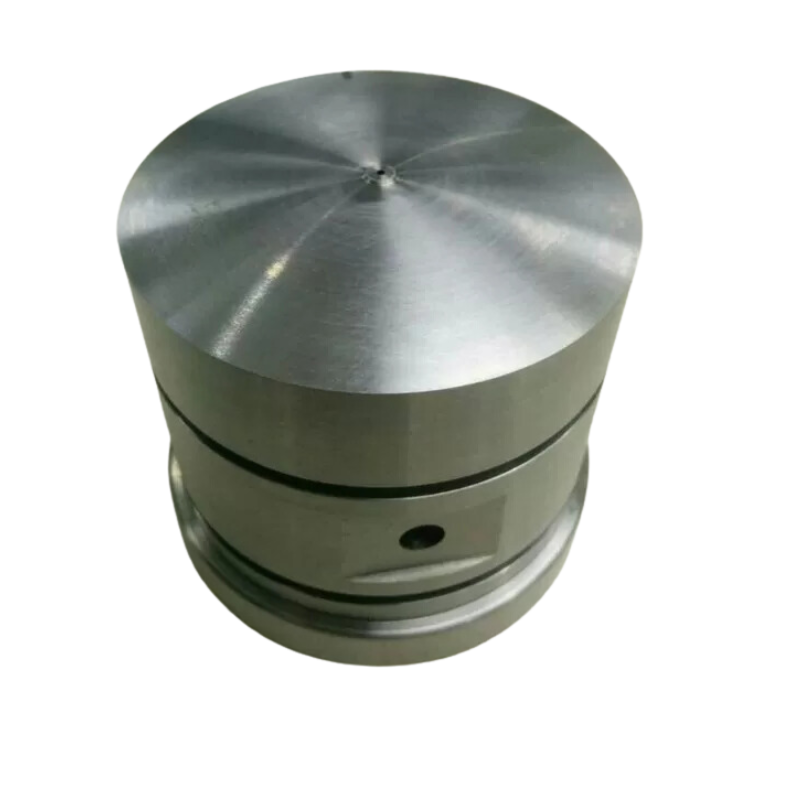

#4 Post-Processing Services

Post-processing can dramatically affect the appearance, strength, and functionality of a 3D printed part. These steps might include heat treatments, surface finishing, or even additional machining. A manufacturer like Suproto provides comprehensive post-processing options allows more flexibility and control over the final product’s characteristics.

#5 Cost and Turnaround Time

While cost-effectiveness is a significant advantage of stainless steel 3D printing, businesses should understand the factors that contribute to the overall cost, such as setup fees, material costs, and post-processing charges. Turnaround time, too, is a vital aspect to consider as it directly impacts project timelines.