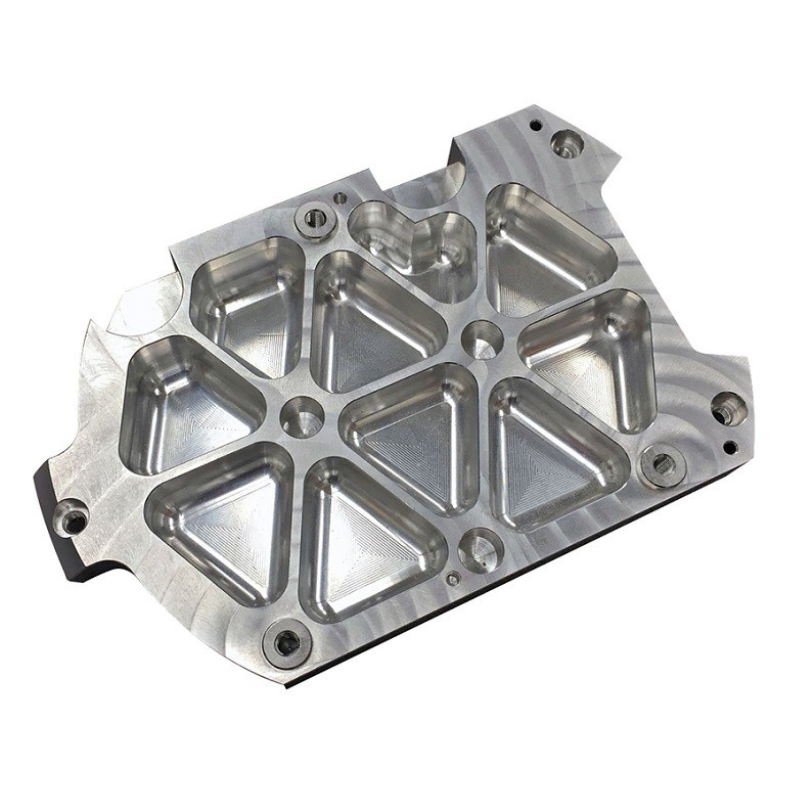

High Precision and Accuracy

Aerospace CNC machining allows for highly precise and accurate manufacturing of parts. This feature is pivotal given the stringent requirements in the aerospace industry, where any inconsistency or flaw can have far-reaching, negative effects. Through computer-directed cutting operations, every part produced exhibits extreme exactness in its dimensions.

Speed and Efficiency

Aerospace CNC machining significantly increases the speed of production by enabling multiple machine setups to produce the same part simultaneously. This feature reduces the opportunities for errors and enhances production efficiency.

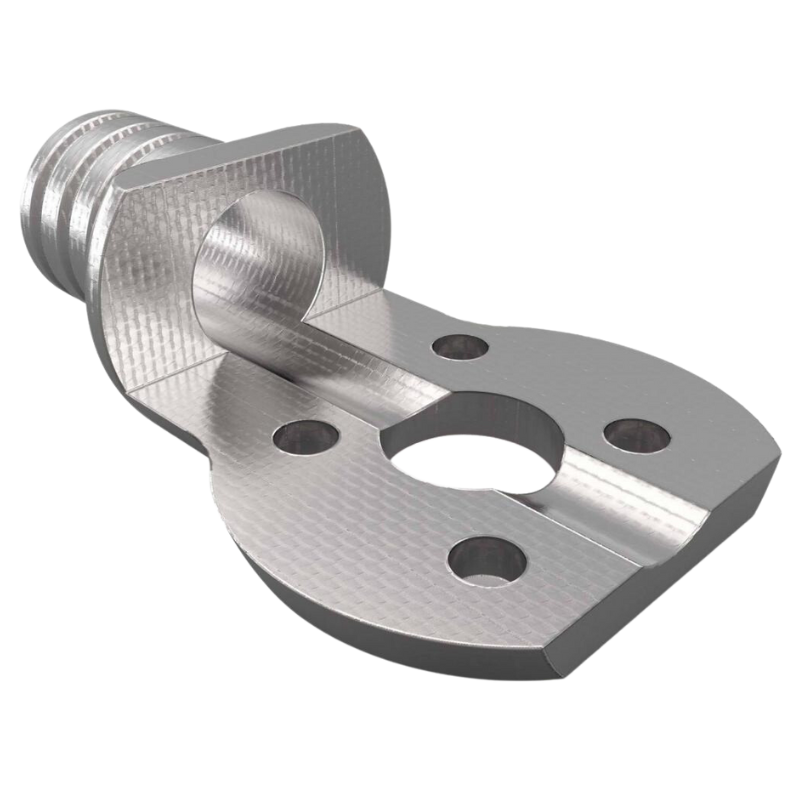

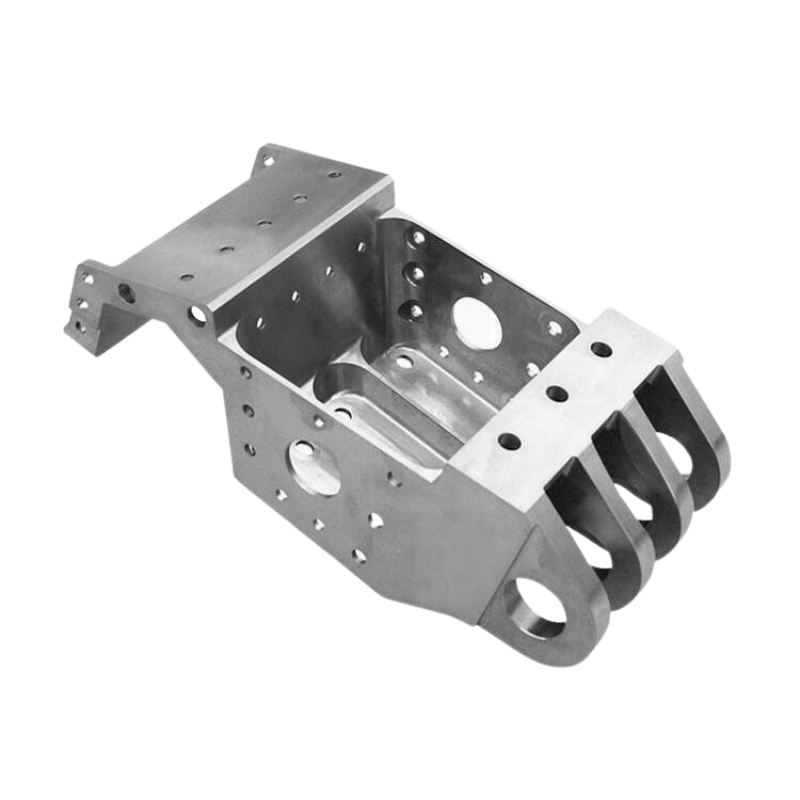

Capability to Handle Complex Geometries

CNC machining can effectively manage intricate designs and complex geometries, a common attribute of aircraft components. For example, consider the case of a complex turbine blade, wherein the precision and consistency provided by CNC machining aerospace parts enables the production of such intricate components with minimal error, even on a large scale.

Consistency in Production

The nature of CNC machining ensures consistency across all manufactured parts. Given computer-directed operations, there is minimal room for human error, resulting in uniform and reliable parts across large production scales.

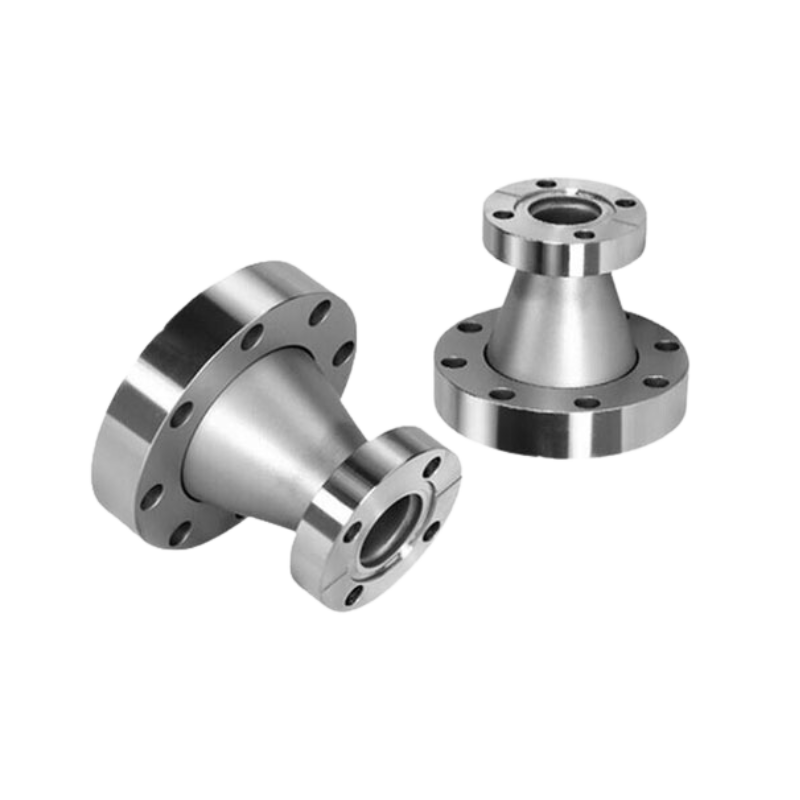

Broad Material Tolerance

Aerospace CNC machining, Suproto, is renowned for its advanced technology and innovation, is capable of broad material tolerance, offering aerospace CNC machining services for a vast range of both plastic and metal materials to meet the rigorous specifications of each unique part.