The EDM wire market size is expected to reach US$ 3,450.17 million by 2028 with CAGR of 6.6% from 2022 to 2028 as reported by Global News Wire, demonstrating the industry’s continuous growth and the increasing reliance on these services. When exploring the potential of wire EDM for every manufacturing process, here are the several considerations that come into play:

#1 Material Compatibility

Not all materials are suitable for wire EDM machining. The material must be electrically conductive for the process to work. Always ensure that the wire EDM service provider can effectively handle the specific material of production parts.

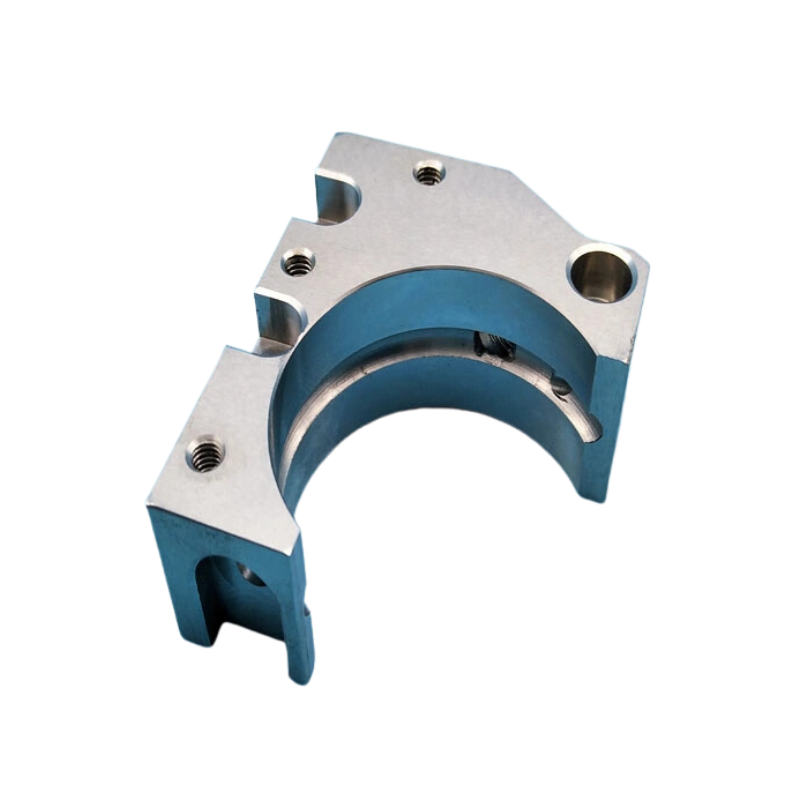

#2 Level of Precision Required

Wire EDM services offer high precision, but the level of precision can vary between providers. Consider the tolerance requirements of the project and ensure the service can meet these needs. For instance, the aerospace and medical industries typically require exceptionally high precision.

#3 Production Volume

Consider the volume of parts needed to produce to cater the business needs. While wire EDM is highly accurate, it’s not the fastest machining method. However, for low to medium volumes, or for prototyping, it’s an excellent option. In my view, it’s like the steady tortoise in the fable—may not be the fastest, but it sure gets the job done flawlessly.

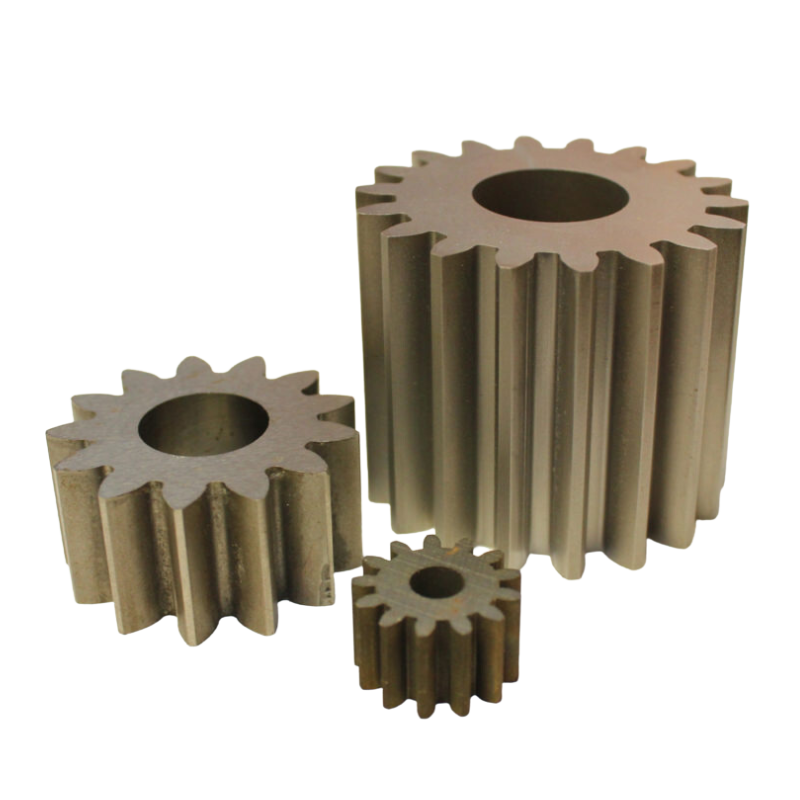

#4 Complexity of the Parts

Wire EDM shines when creating complex, intricate parts that other machining methods struggle with. Consider the complexity of the design when deciding on a service. More complex designs may benefit more from wire EDM.

#5 Reputation and Experience

Look at the provider’s track record, expertise, and customer reviews. These attributes can help business owners to determine whether they run in this industry in a timely and precise manner. A reputable provider of EDM wire services like Suproto can ensure high-quality output and reliable services.