#1 Quality of Material

According to Kash Flow, striking the balance between quality and efficiency is, arguably, one of the most difficult challenges of doing business. The first and foremost aspect to consider when seeking sheet metal fabrication services is the quality of the material. The metal used should be of high caliber to guarantee durability, functionality, and optimal performance of the finished product.

#2 Technical Capabilities

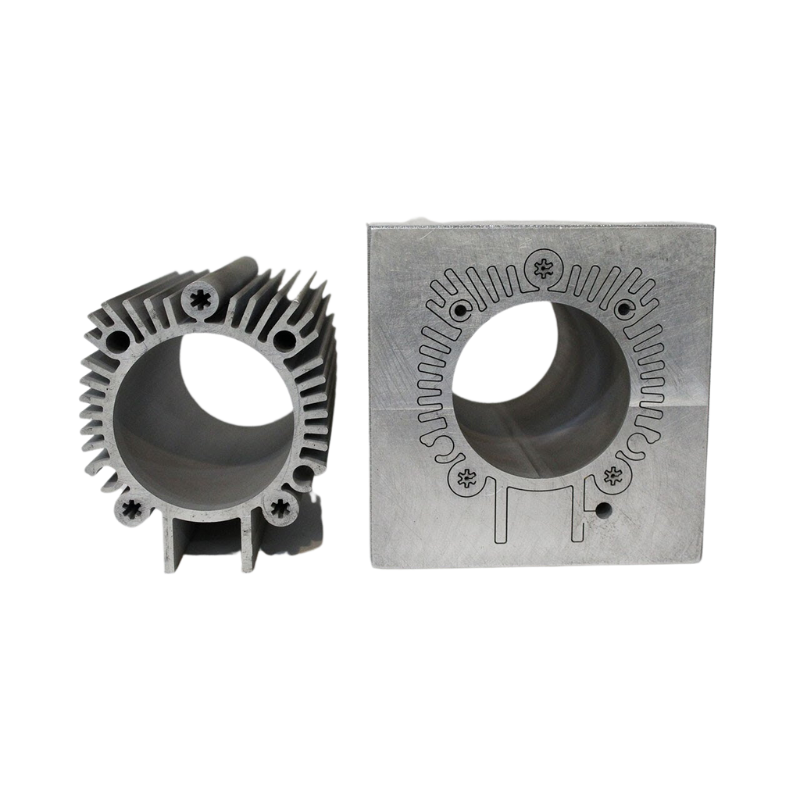

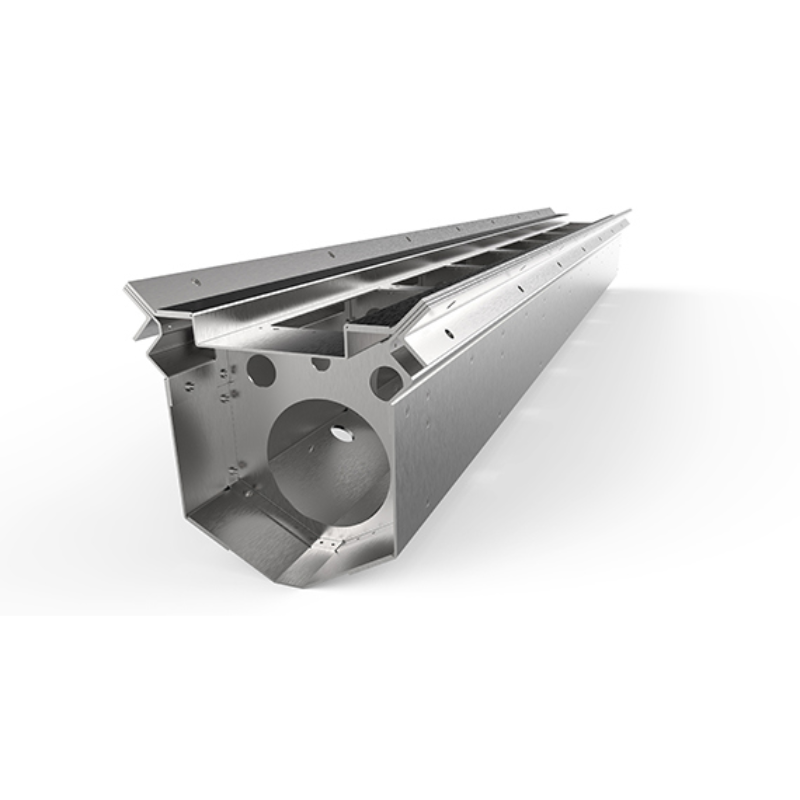

Another essential factor to weigh is the technical prowess of the fabricator. The fabrication company should have a broad spectrum of capabilities to handle the wide variety of requirements that the projects might entail. At Suproto, our team is adept at various fabrication methods, such as bending, cutting, punching, and welding.

#3 Delivery Time

Timeliness of delivery is a significant consideration that often weighs heavily on decision-making. The ability to meet deadlines is a testament to a fabricator’s reliability and operational efficiency. For instance, delayed orders can disrupt business operations, leading to potential losses. Therefore, it is critical to choose a fabricator that respects the importance of time.

#4 Cost Effectiveness

The aspect of cost-effectiveness comes into play. While it’s important to find a fabricator that offers competitive pricing, this should not come at the expense of quality. For example, the cheapest option is not always the best one, especially if it means compromising on the quality, durability, or performance of the product. Striking the right balance between cost and quality can lead to higher returns in the long term.