#1 Performance and Quality

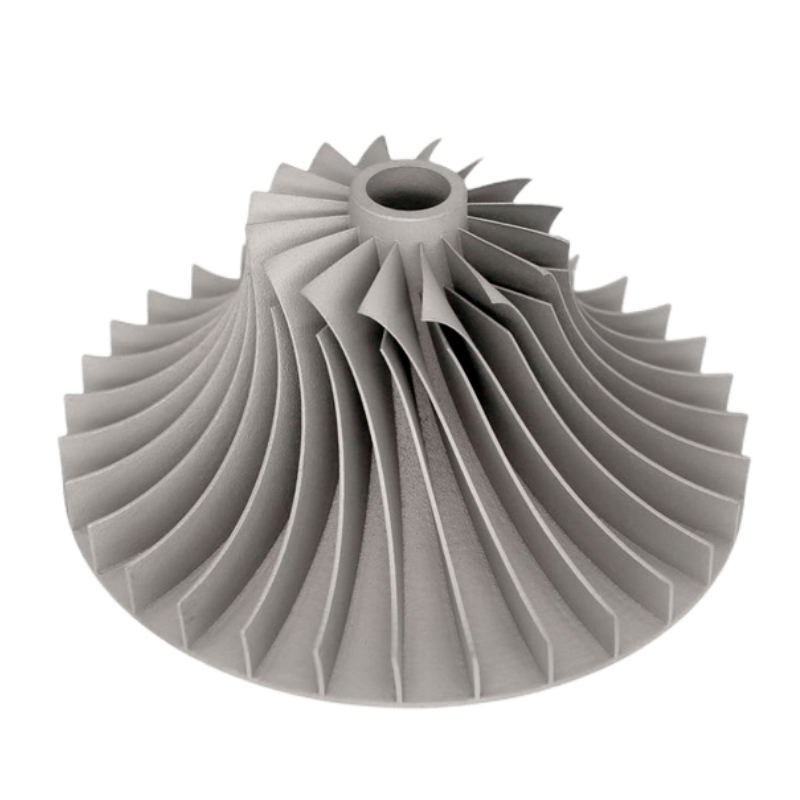

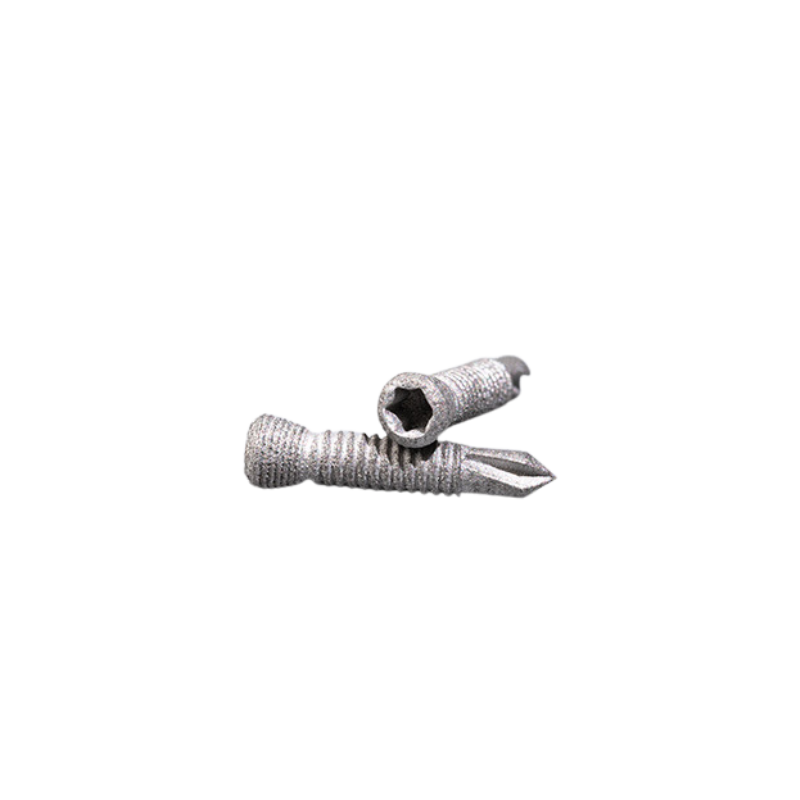

The quality of the final product is a critical consideration when purchasing a Selective Laser Melting (SLM) printer. According to ScienceDirect, SLM is capable of producing fully dense near-net-shape components without the need for post-processing compared to conventional manufacturing methods. Also, it can produce complicated and exquisite workpieces via CAD.

#2 Material Compatibility

When choosing an SLM printer, it’s necessary to consider its material compatibility. This includes the types of metal powders the printer can process effectively and the quality of the resultant parts. SLM technology has shown excellent results with various metal and non-metallic materials. Depending on the specific requirements, for example, it’s crucial to select an SLM printer that is compatible with the materials plan.

#3 Printing Speed

The speed at which an SLM printer can produce parts is a key consideration. Suproto knows that it is particularly important for businesses aiming to meet high demand and reduce lead times. I believe SLM technology, in general, can process metal powder quickly to obtain the necessary parts faster compared to traditional manufacturing methods.

#4 Cost-Effectiveness

Cost-effectiveness is a vital factor to consider when purchasing an SLM printer. This not only includes the initial investment for the machine but also the ongoing costs associated with materials, maintenance, and energy consumption. A research study found that SLM technology can help reduce costs by eliminating the need for molds, thus decreasing production time.

#5 EHS Compliance

Environmental, health, and safety compliance are paramount when investing in an SLM printer. Since the process involves the use of high-power lasers and potentially hazardous materials, it’s essential to ensure that the machine adheres to all relevant safety and environmental regulations.