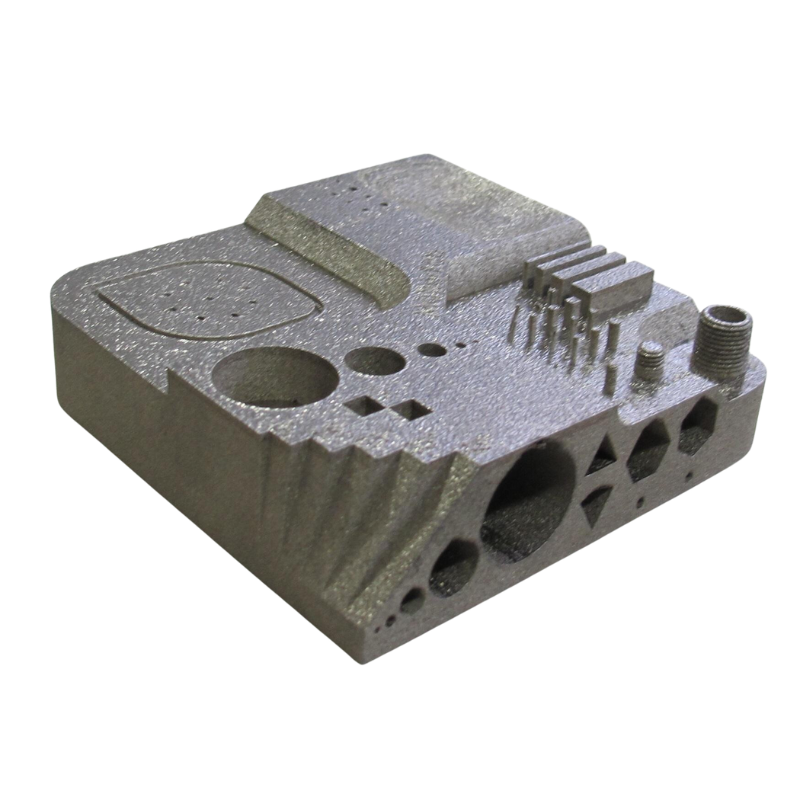

Understanding Requirements

It’s crucial to understand the projects needs and how the service can cater to them. For example, the scope of the project, the level of detail in the designs, the materials anyone intends to use, and the quantity of parts needed are all essential factors to consider. It’s also vital to establish whether it requires end-use parts or prototypes, as this will influence the choice of technology and materials.

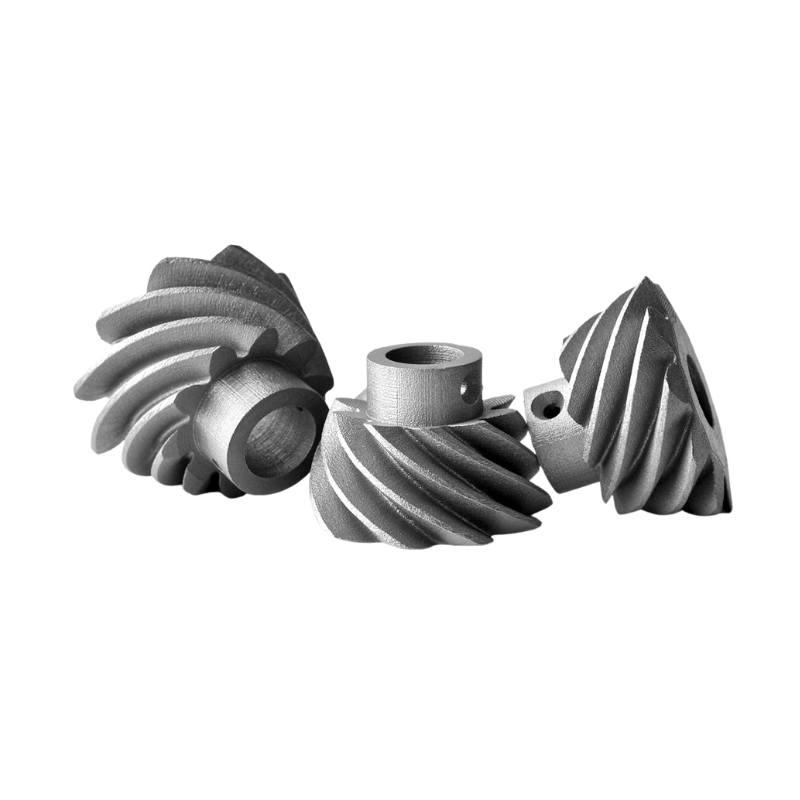

Expertise and Capabilities

When searching for a metal 3D printing service, the provider’s expertise and capabilities should align with the project’s requirements. I suggest investigating the range of technologies and materials they offer, their experience in the specific industry, and their track record of delivering high-quality, and reliable products.

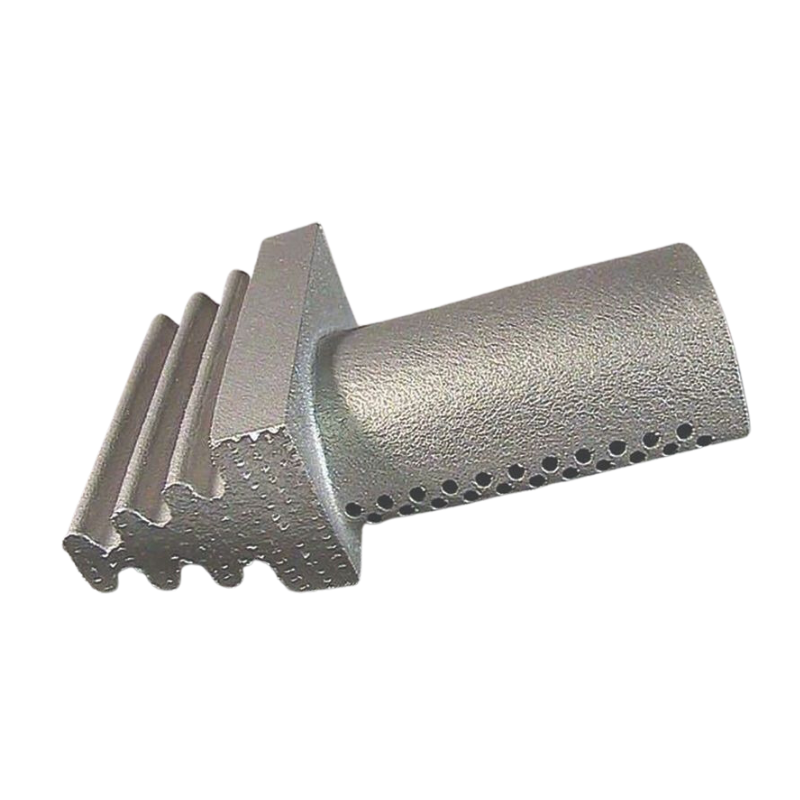

Quality Assurance and Standards

According to AMFG, quality assurance (QA) is arguably the most important and yet one of the most challenging steps in 3D printing. Ensure that the provider operates under recognized standards like Sheet Metal Fabrication ISO 9001 or AS9100 and that they have robust quality control procedures in place. This includes part inspection methods and the ability to provide full traceability of materials and processes.

Turnaround Time and Cost

Time and cost efficiency is a significant factor when selecting a metal 3D printing service. Understanding the service provider’s turnaround times and how they align with the project’s timelines is essential. Suproto, with its reputation for prompt delivery and competitive pricing, positions itself as a worthy consideration in this regard.