Statista Research Department shows the demand forecast for injection molded plastics in the United States from 2019 to 2025. It is forecasted that the U.S. demand for polypropylene (PP) injection molded plastics will amount to some 11.5 million tons in 2025. Choosing an injection molding USA can be a key choice that has a big impact on the project’s success. Here are the top 5 things to think about:

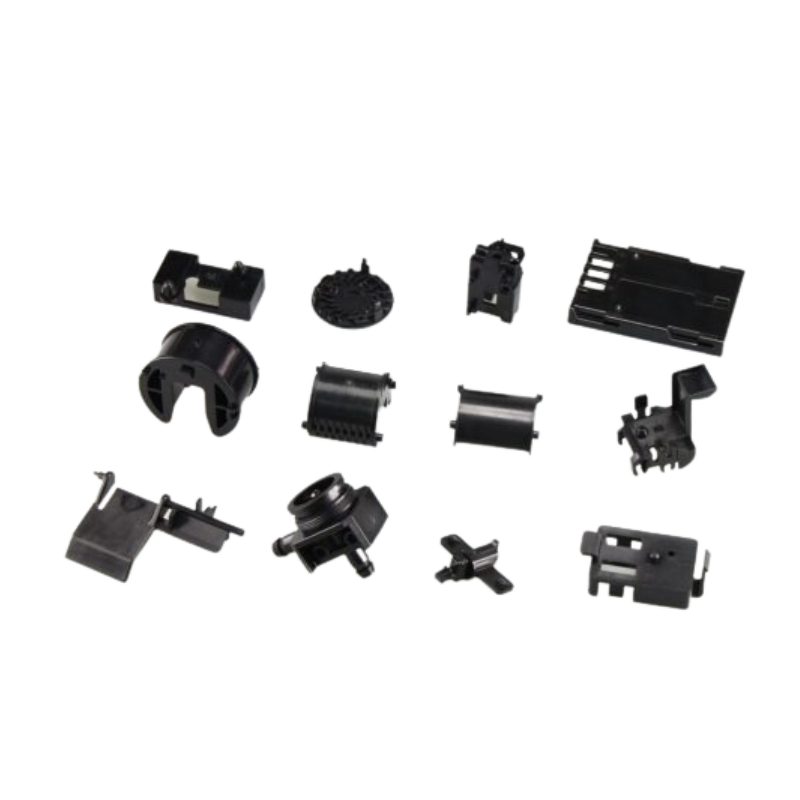

#1 Material Properties

When opting for injection molding, it is crucial to understand the properties of the materials the clients are working with. Different materials behave differently under certain conditions. For example, in making a heat-resistant component, a high-performance thermoplastic would be a suitable choice.

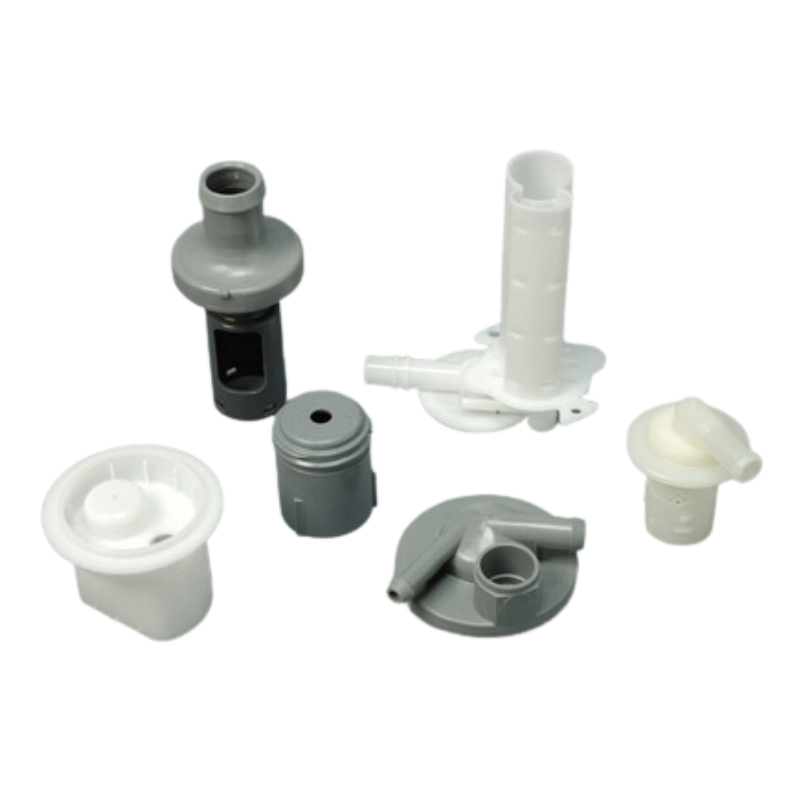

#2 Mold Design

The complexity of every product design influences the mold design. It’s vital to work closely with the manufacturer to ensure that the mold design is optimized for the injection molding process. I believe automotive parts often have intricate designs that require precision molds.

#3 Production Volume

At Suproto, we understand that the scale of business production is vital. For large-scale production, injection molding is cost-effective. However, for smaller quantities, alternative methods might be more economical. For instance, it is a start-up company producing a limited number of prototype parts.

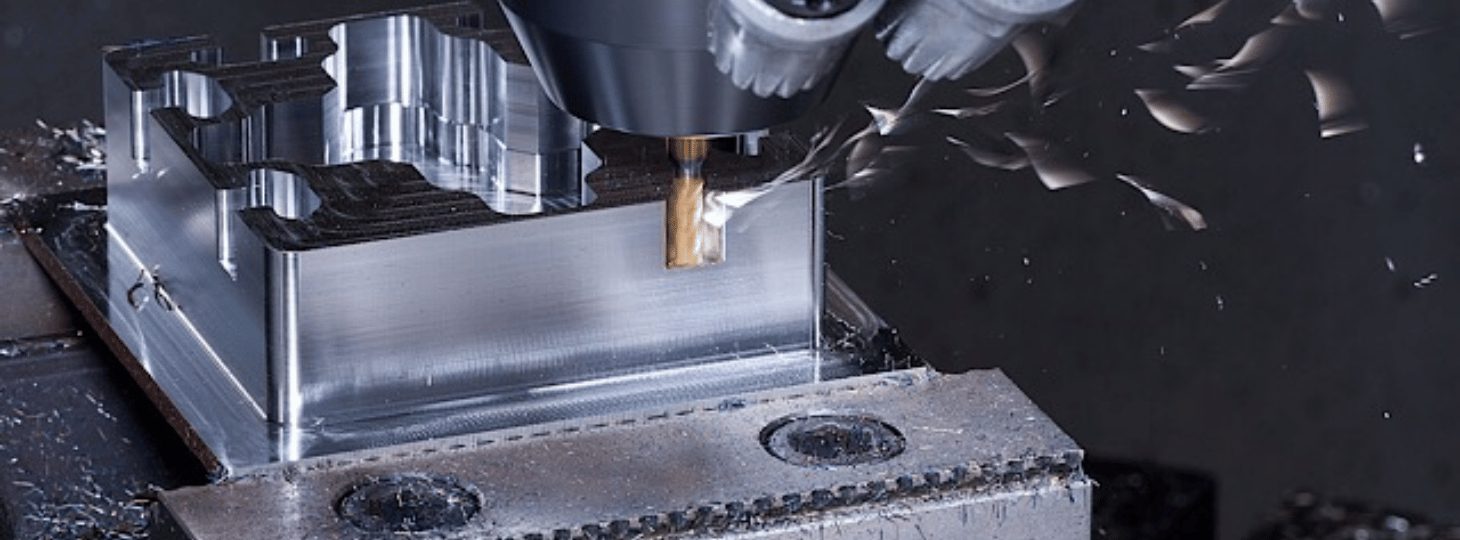

#4 Project Timeline

The time it takes from the initial design phase to final production is crucial, especially in a competitive market. Understanding and planning around the lead times of injection molding services, which can be slow due to custom tooling requirements, is imperative.

#5 Location and Logistics

Considering the location of the injection molding company can have a significant impact on logistics and costs. Choosing a company in a strategic location can reduce transportation costs and lead times. For example, a business located in the Midwest might benefit from partnering with a local injection molding company for faster turnaround times and lower transportation costs.