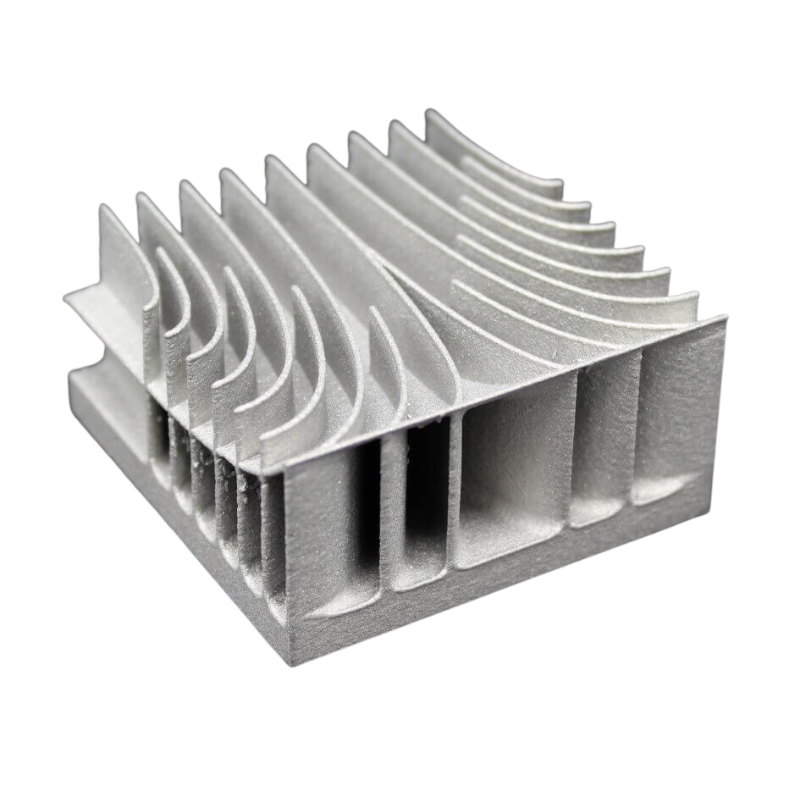

#1 Selection and Compatibility

When selecting a 3D printing service, it’s critical to ensure that they offer materials compatible with the specific applications. Different materials have various properties such as strength, flexibility, and temperature resistance, which must be considered based on the project requirements.

#2 Volume and Scalability

It’s important to evaluate the production capacity of the 3D printing service provider. For large-scale manufacturing, I believe there’s a need for a service that can handle high volumes of production without compromising on quality or lead times.

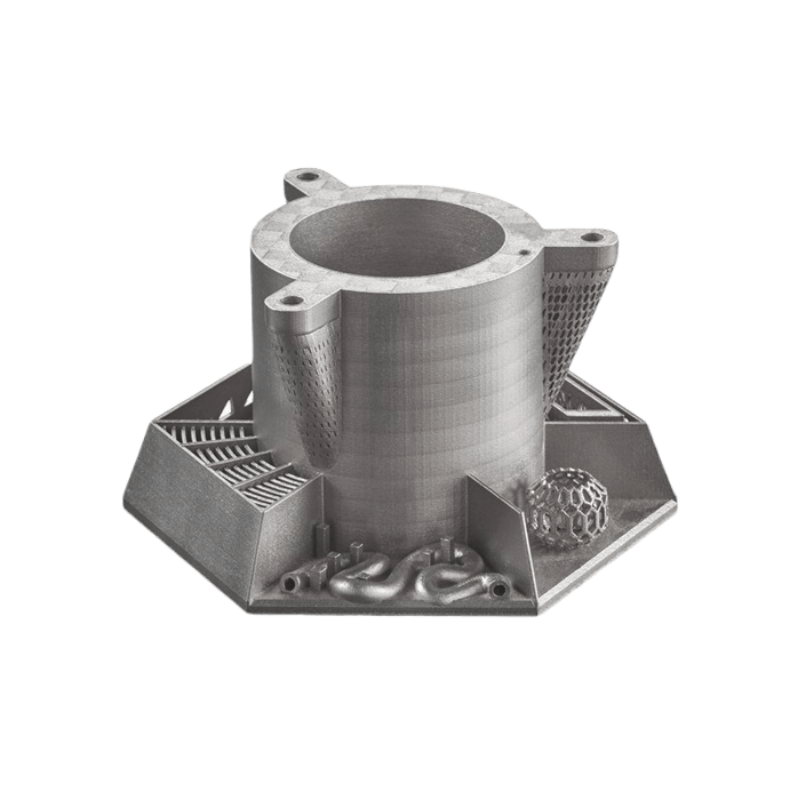

#3 In-House Expertise

In evaluating the in-house expertise of a 3D printing service provider, it is important to ascertain that experts can offer insights and support throughout the 3D printing process, which is fundamental for the success of the project. For example, experts can assist in identifying strategic opportunities, optimizing design, and streamlining processes are particularly beneficial for businesses.

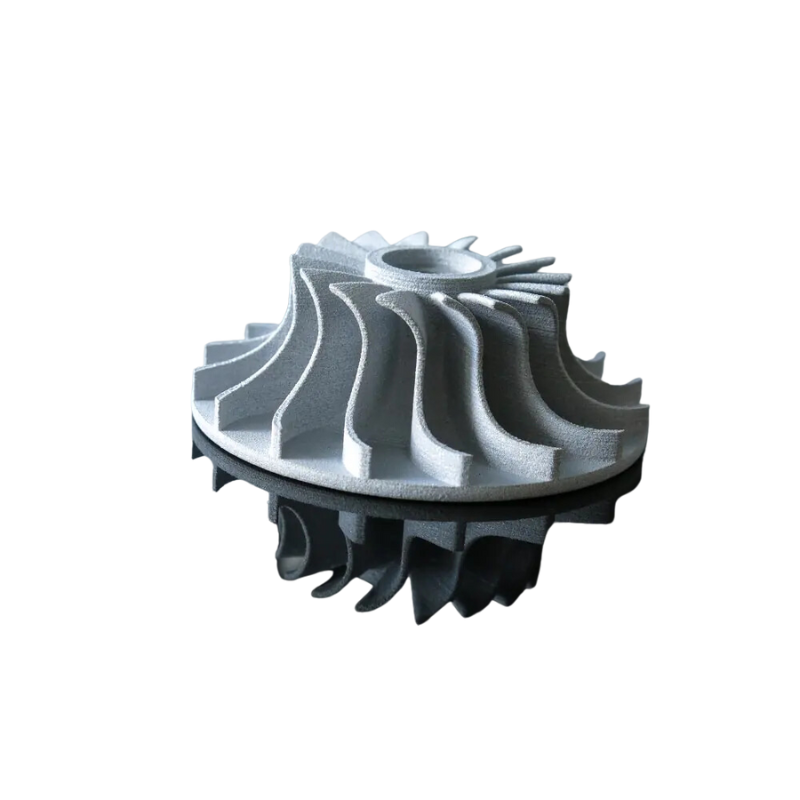

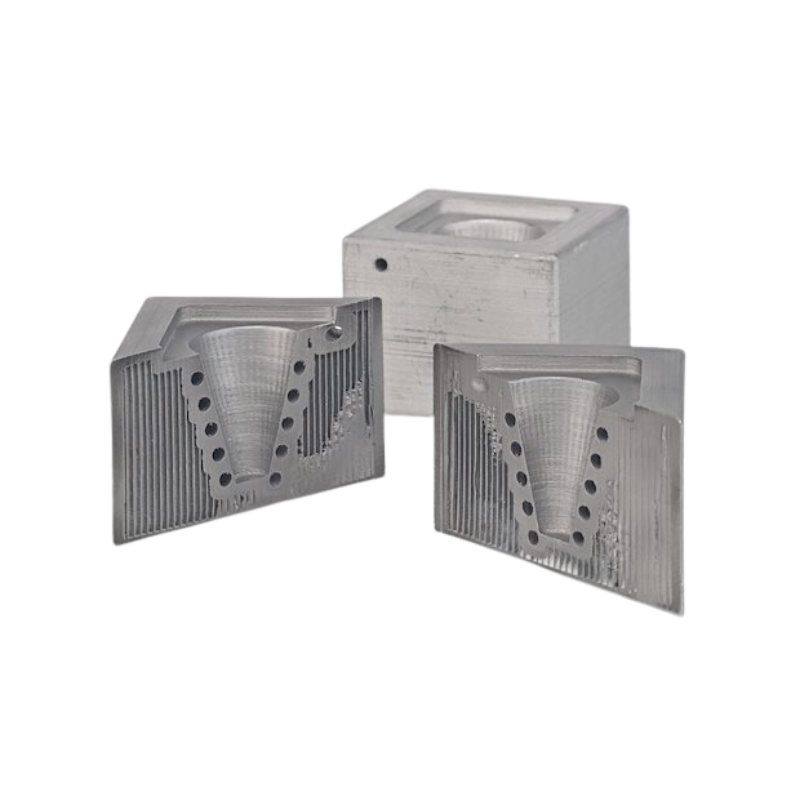

#4 Integration of Existing Methods

It’s essential that the 3D printing service is capable of integrating the printed components with existing manufacturing methods, ensuring that the final products meet the required specifications and quality standards like Suproto.

#5 Return on Investment

Analyze the cost structures of different 3D printing services and weigh them against the potential return on investment. The service should not only be affordable but also bring value to the business through quality, efficiency, and innovation.