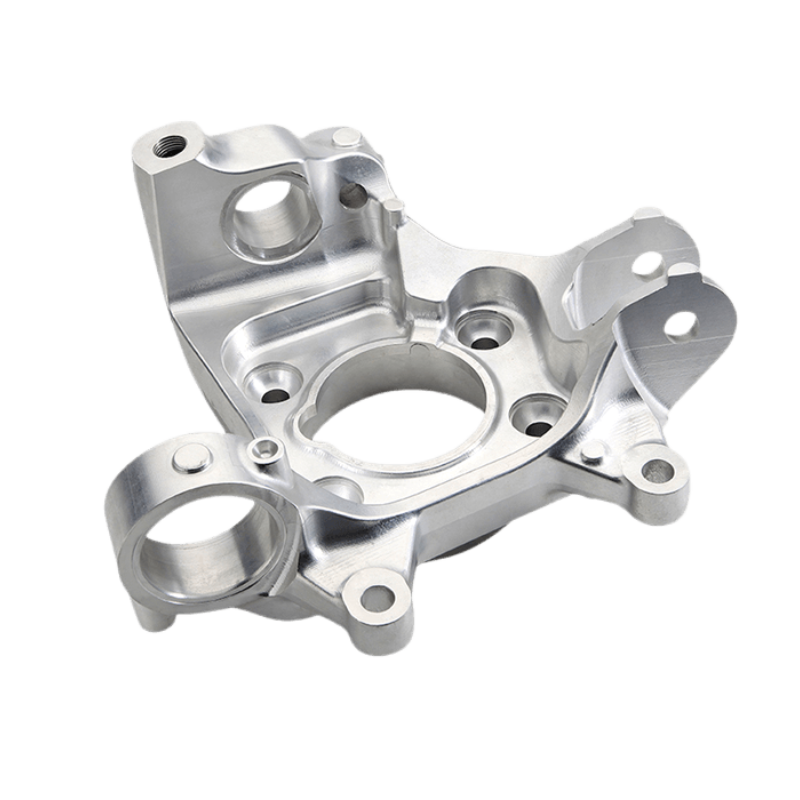

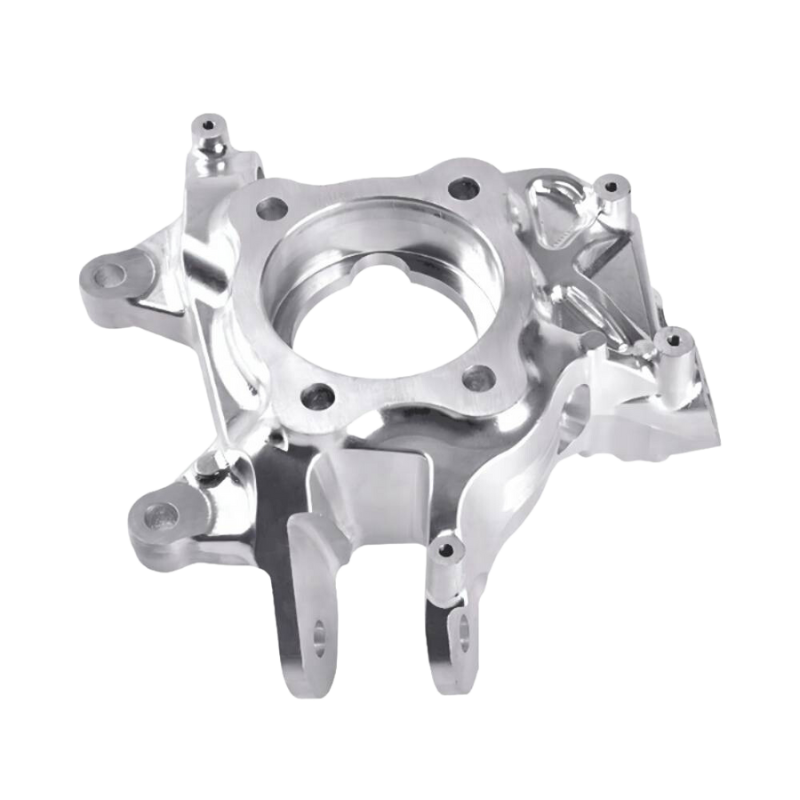

#1 Quality of Material

The quality of the material used in the production of CNC milled parts can significantly impact the performance and longevity of the parts. We at Suproto understand that it is essential to ensure the use of high-quality materials for our CNC milling operations.

#2 Precision and Tolerance

When sourcing CNC milled parts, attention must be given to the level of precision and tolerance the parts provide. For example, ensure that the supplier can deliver parts with the tight tolerances and accuracy that the applications require.

#3 Finishing Choices

The finishing of the milled parts impacts both aesthetics and performance. An “as machined” finish may be sufficient for some applications, but it’s important to understand that this may leave tool marks and result in a surface roughness of approximately 3.2 μm. If a smoother finish is required, additional finishing processes such as bead blasting or powder coating could be considered.

#4 Cooling System

One critical consideration when buying CNC milled parts is the cooling system employed during the machining process. A study compared different cooling systems and found liquid nitrogen-based cryogenic cooling to be a cleaner substitute for the traditional flood cooling system. Thus, understanding the cooling method used in the production of CNC milled parts can provide insights into their quality and durability.

#5 MQL Parameters

Another crucial consideration is the Minimum Quantity Lubrication (MQL) parameters used during the CNC milling process. The MQL parameters, such as flow rate, nozzle angle, and air pressure, significantly affect the overall quality of the finished parts. Understanding these parameters can provide a more comprehensive view of the manufacturing process.