Given that the sheet metal market size is valued at USD 408.31 billion by 2028 and is expected to grow at a rate of 4.70% for the period of 2021 to 2028 according to Data Bridge Market Research. Several considerations are essential to ensure the chosen partner aligns with the company’s values, manufacturing needs, and business goals. Below are the ff:

#1 Capabilities

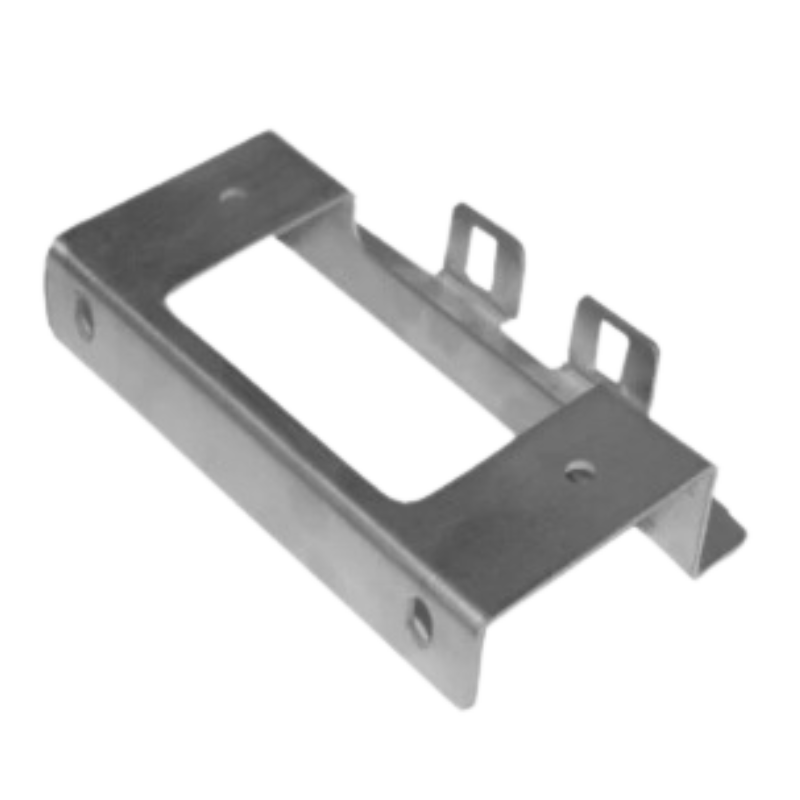

Consider the full range of services offered by sheet metal fabricators in Monterrey, Mexico, or any other region. Fabricators should provide a comprehensive range of services, from basic cutting and bending to complex assembly and system integration. This will ensure they can meet the current and future project needs, enhancing efficiency and reducing the need to use multiple vendors.

#2 Quality Assurance

This includes adherence to international quality standards, regular audits, and a strong track record of quality. Ask for certifications. Examples are ISO 9001 or AS9100 to ensure the fabricator adheres to globally recognized quality standards. I’ve found that a commitment to quality assurance not only protects the integrity of the product but also instills confidence in all stakeholders involved in a project.

#3 Technological Advancements

The use of advanced technologies can significantly enhance the precision and efficiency of sheet metal fabrication. Ensure that the chosen sheet metal fabricators in Monterrey, Mexico, use state-of-the-art technology, such as CNC machines, laser cutters, and automated systems. Technological advancements can provide high precision, reduce waste, and improve production speed.

#4 Workforce Skills and Experience

Consider fabricators with a well-trained and experienced workforce, capable of handling complex projects and meeting tight deadlines. These skills ensure the project is completed to the highest standards and delivered on time. With a partner like Suproto, anyone can ensure quality, timeliness, and cost-effectiveness in the sheet metal fabrication projects.