Simplified Machining

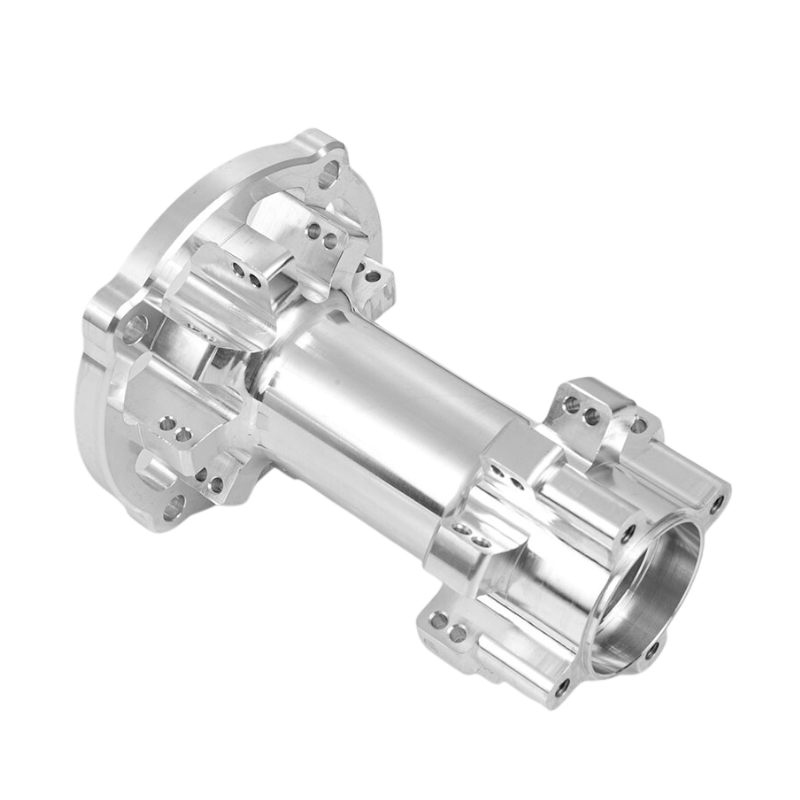

Here’s something we can both agree on, the primary advantage of 5 axis CNC machining is its ability to easily handle complex parts. By rotating on five different axes simultaneously, these machines can reach every angle of the workpiece, making the machining process much simpler and more efficient.

Reduction in Setup Time

5 axis CNC machining drastically reduces the setup time by eliminating the need for multiple setups. As a result, this allows for faster production times and reduced labor costs. Additionally, with 5 axis machining, the cutting tool can access the part in five directions instead of three, which enables machining up to 5 faces in just one operation, saving time and money

Increased Tool Life

By constantly maintaining an optimal cutting position, 5 axis CNC machines reduce tool wear, thus increasing the life of the tool and reducing maintenance costs. This method also enables low cycle times by eliminating more material each time the tool passes, ensuring faster, more accurate, and more cost-effective results