Flexibility in Design

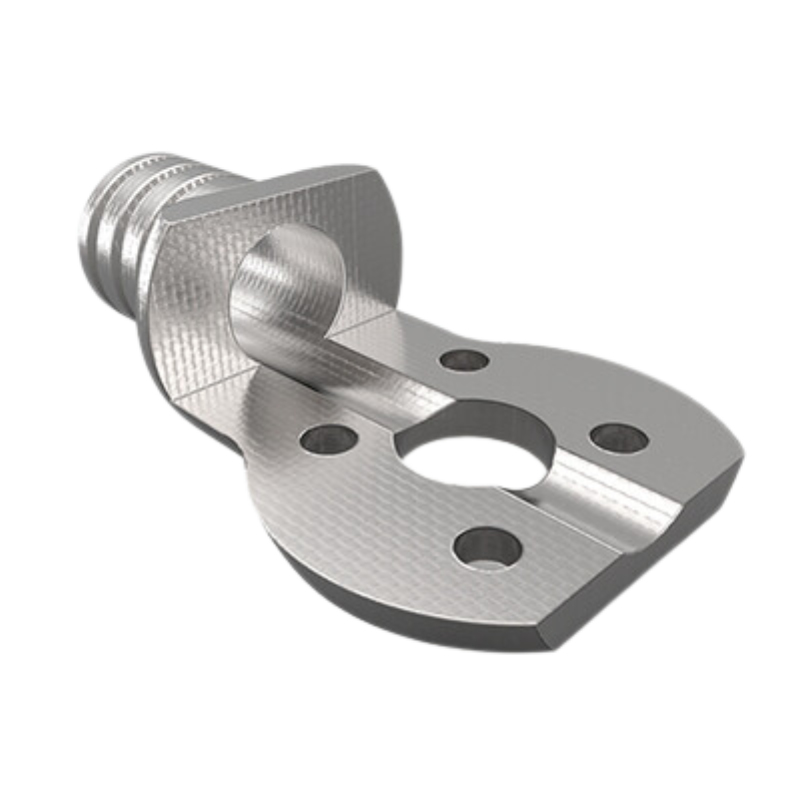

A 3 axis CNC machine can produce a wide array of parts, ranging from simple to complex designs. This technology handles most geometries and straightforward components efficiently, making it ideal for a variety of manufacturing needs. For example, it can effectively create parts like gears, brackets, and engine components with relative ease.

Fine Detail and Precision

Due to their automated nature, 3 axis CNC machines can produce highly accurate parts which reduces the chance of human error. The machine cuts along the X, Y, and Z axes, allowing for extremely precise control over the milling process. But that’s not all, this level of precision makes it perfect for creating components for industries that require high accuracy, like aerospace or medical devices.

Wide Range of Material Compatibility

The 3 axis CNC milling process can work with a vast array of materials, including metals like aluminum and steel, as well as plastics, wood, and composites. I can vouch that whether the need is to machine robust metal parts or intricate plastic pieces, Suproto provides versatility.